Automatic detecting method of elevator and elevator control device

A point inspection and elevator technology, which is applied in the field of elevator control devices, can solve problems such as undetectable and long time for point inspection, and achieve the effect of efficient automatic point inspection operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

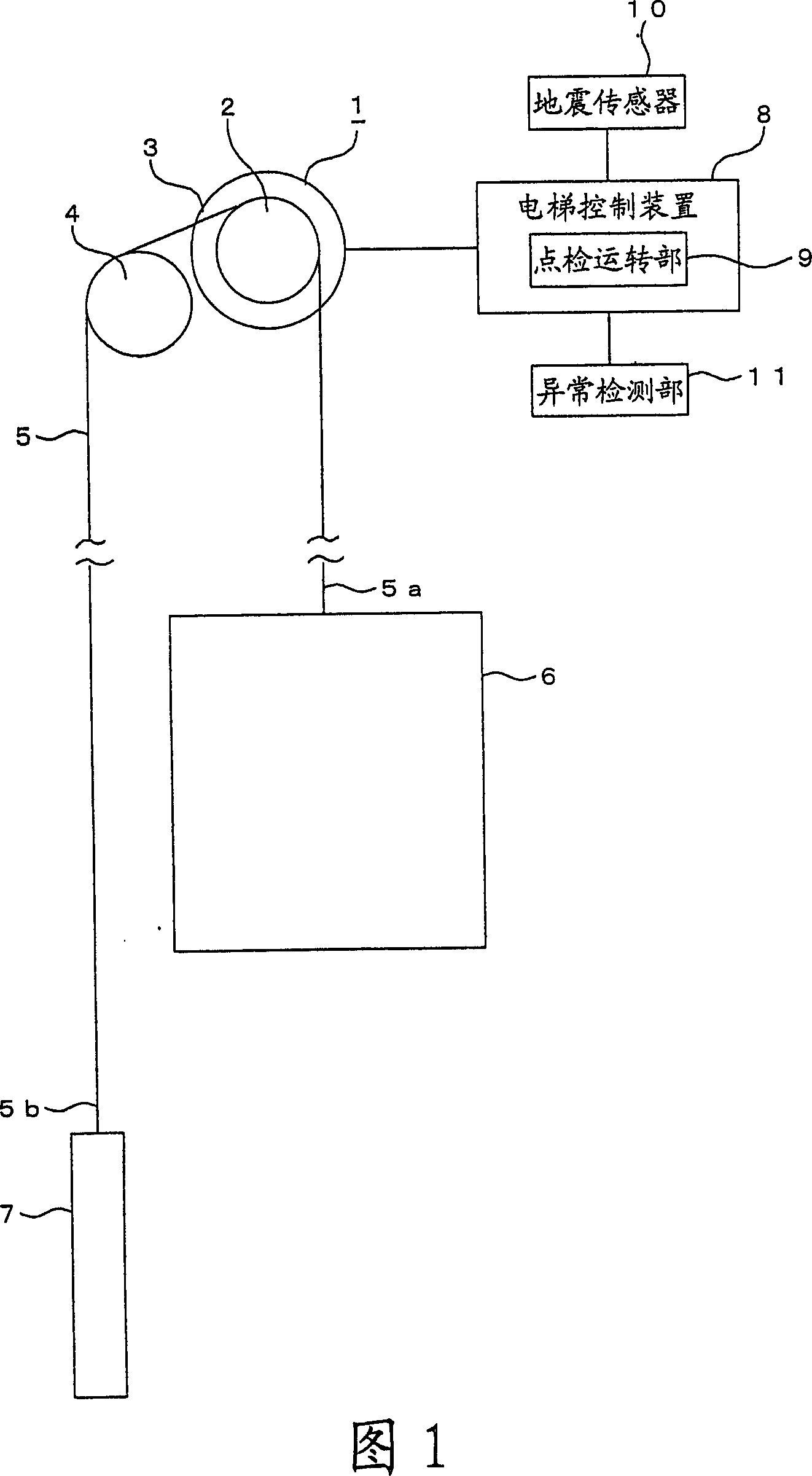

[0012] Fig. 1 is a block diagram showing an elevator apparatus according to Embodiment 1 of the present invention. In the drawing, a driving device (hoist) 1 is provided on the upper part of the hoistway. The drive device 1 has a drive pulley 2 and a drive device main body 3 . The driving device main body 3 has a motor unit that rotates the driving pulley 2 and a braking unit that brakes the rotation of the driving pulley 2 .

[0013] In the vicinity of the drive device 1 there are deflector wheels 4 . A plurality of (only one is shown in the figure) main ropes 5 are wound around the drive pulley 2 and the deflection pulley 4 . The main cable 5 has first and second end portions 5a, 5b. The car 6 is connected to the first end portion 5 a of the main rope 5 . A counterweight 7 is connected to the second end portion 5 b of the main cable 5 . That is, the car 6 and the counterweight 7 are suspended in the hoistway by the main rope 5, and are raised and lowered in the hoistway...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com