Electro-hydraulic manifold assembly with mounted pressure sensors

A technology for manifolds and assemblies, applied in the field of manifold assemblies, can solve the problems of increasing assembly complexity, size and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

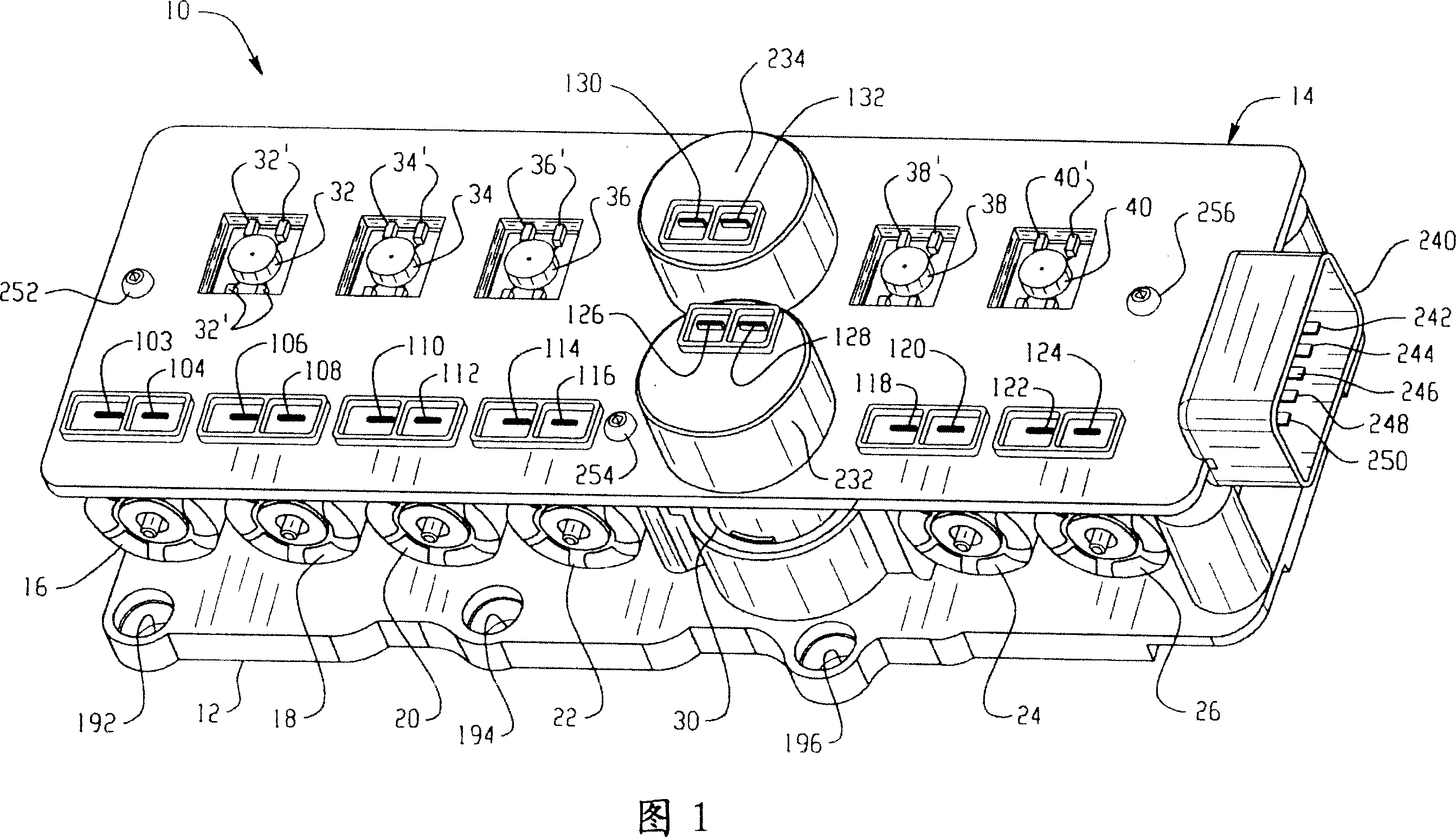

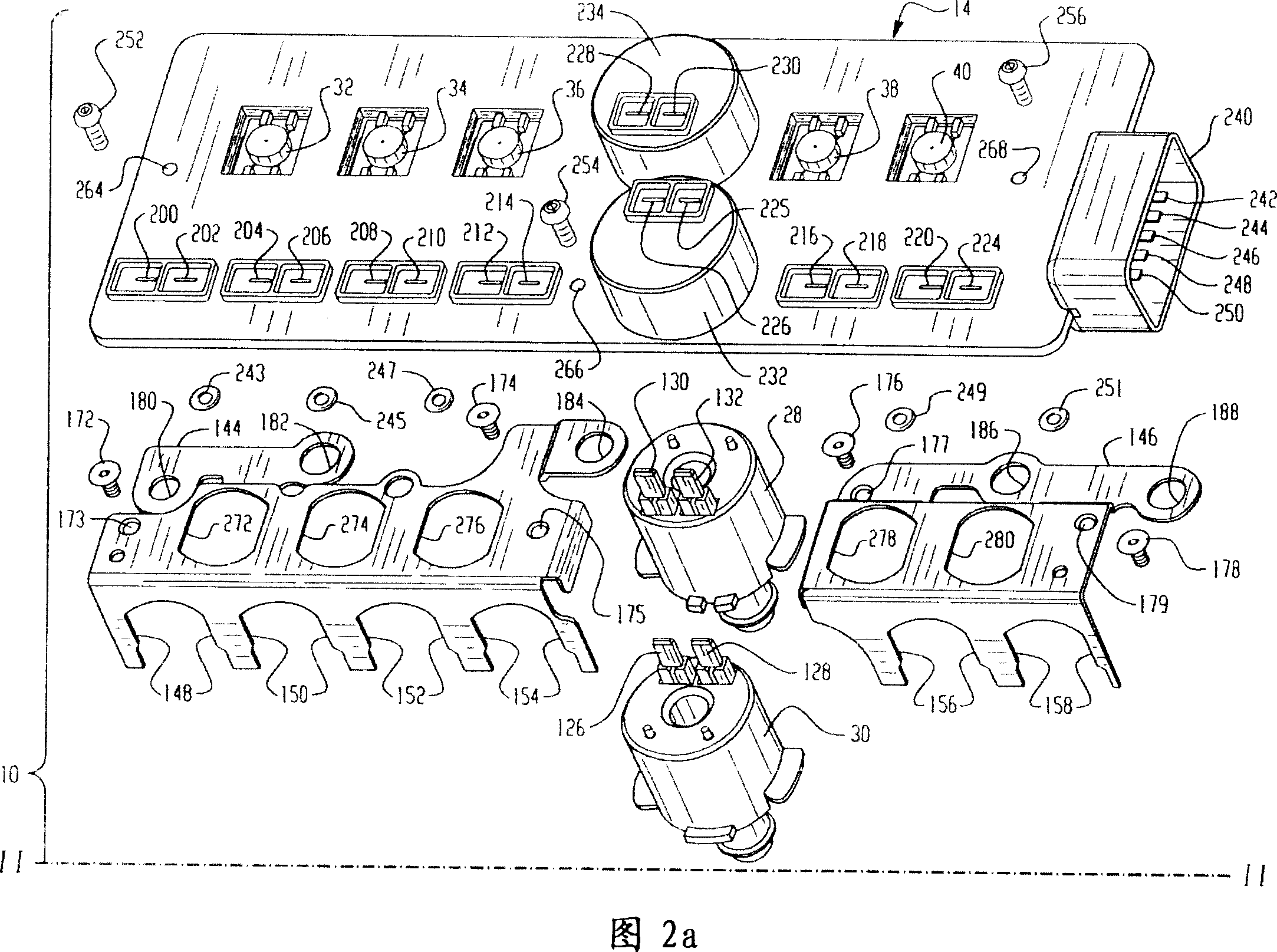

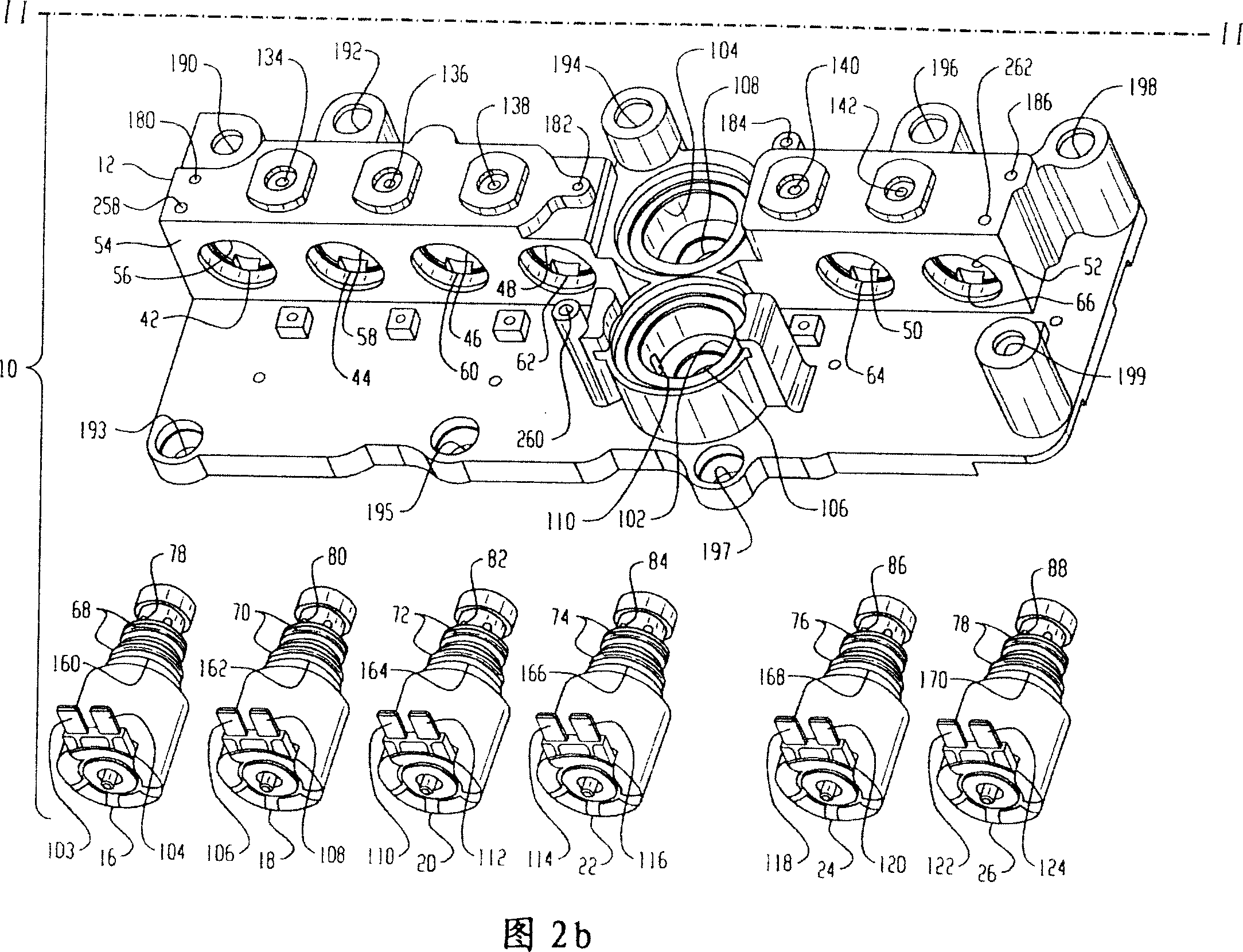

[0017] 1 to 5, one embodiment of the present invention is indicated generally at 10 and includes a manifold body 12, an electrical interface generally indicated at 14 and a plurality of solenoid valves 16, 18, 20, 22, 24, 26, 28, 30. Although these figures show a lead frame as the interface 14, the interface 14 can be any structure that distributes communication signals and power, such as fiber optic cables, plated traces, flex circuits, wiring, wireless interfaces, etc., as will be described below. Explain in more detail.

[0018] Interface 14 includes a plurality of pressure transducers or transducers 32, 34, 36, 38, 40, each having leads secured or connected to conductive strips indicated by primed transducer reference numerals respectively .

[0019] The manifold body 12 has a plurality of valve chambers 42, 44, 46, 48, 50, 52 formed horizontally in a vertically extending side 54 of the manifold body 12, each valve chamber having a valve chamber 56, 58, 60, 62, 64, 66 r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com