Electronic water heater

A water heater and electronic technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of unreasonable design of power component circuit heating coils and water channels, endangering the personal safety of users, and low thermal efficiency of water heaters. Achieve the effect of easy mastering and large-scale production, long working hours and strong driving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

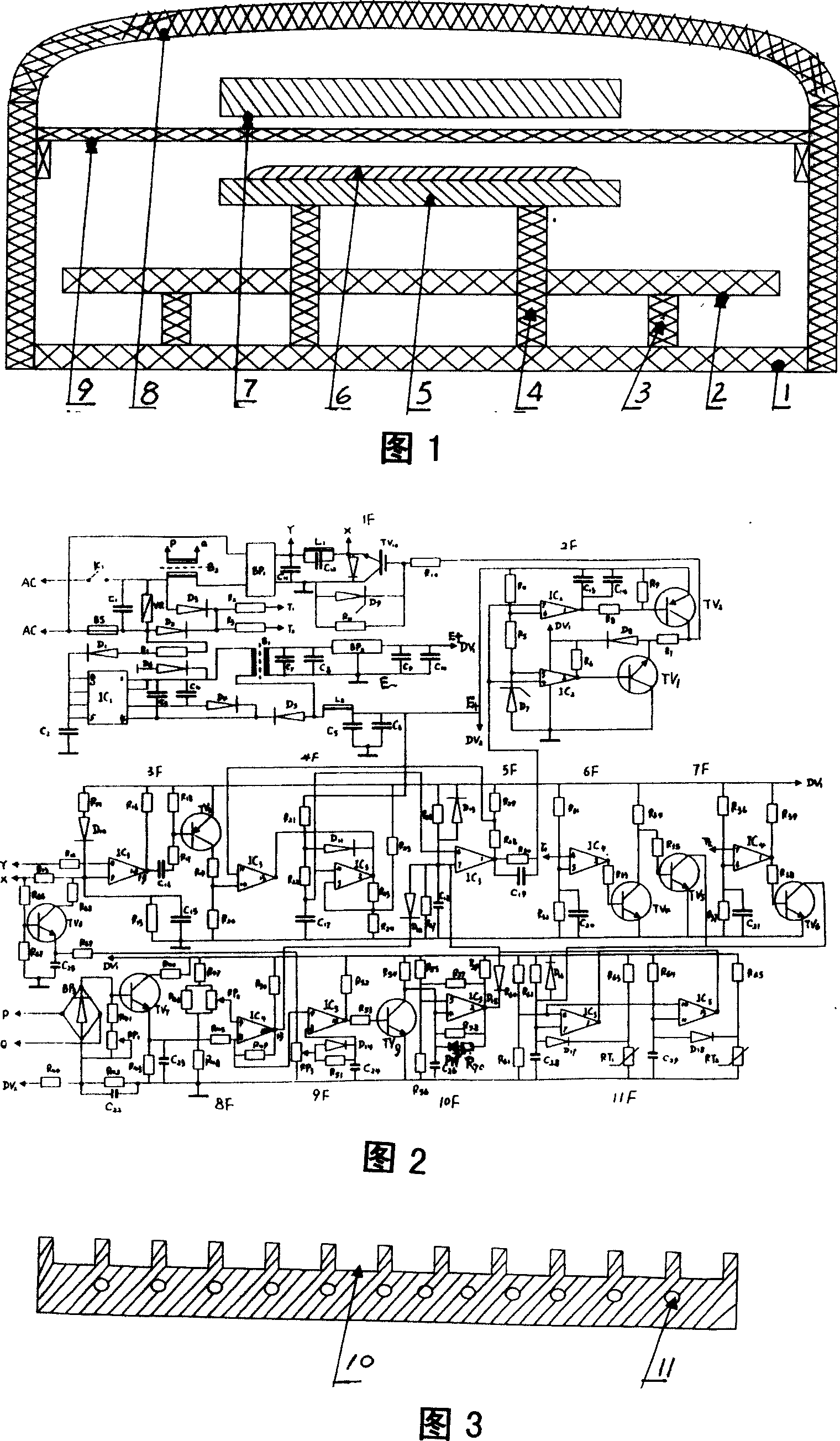

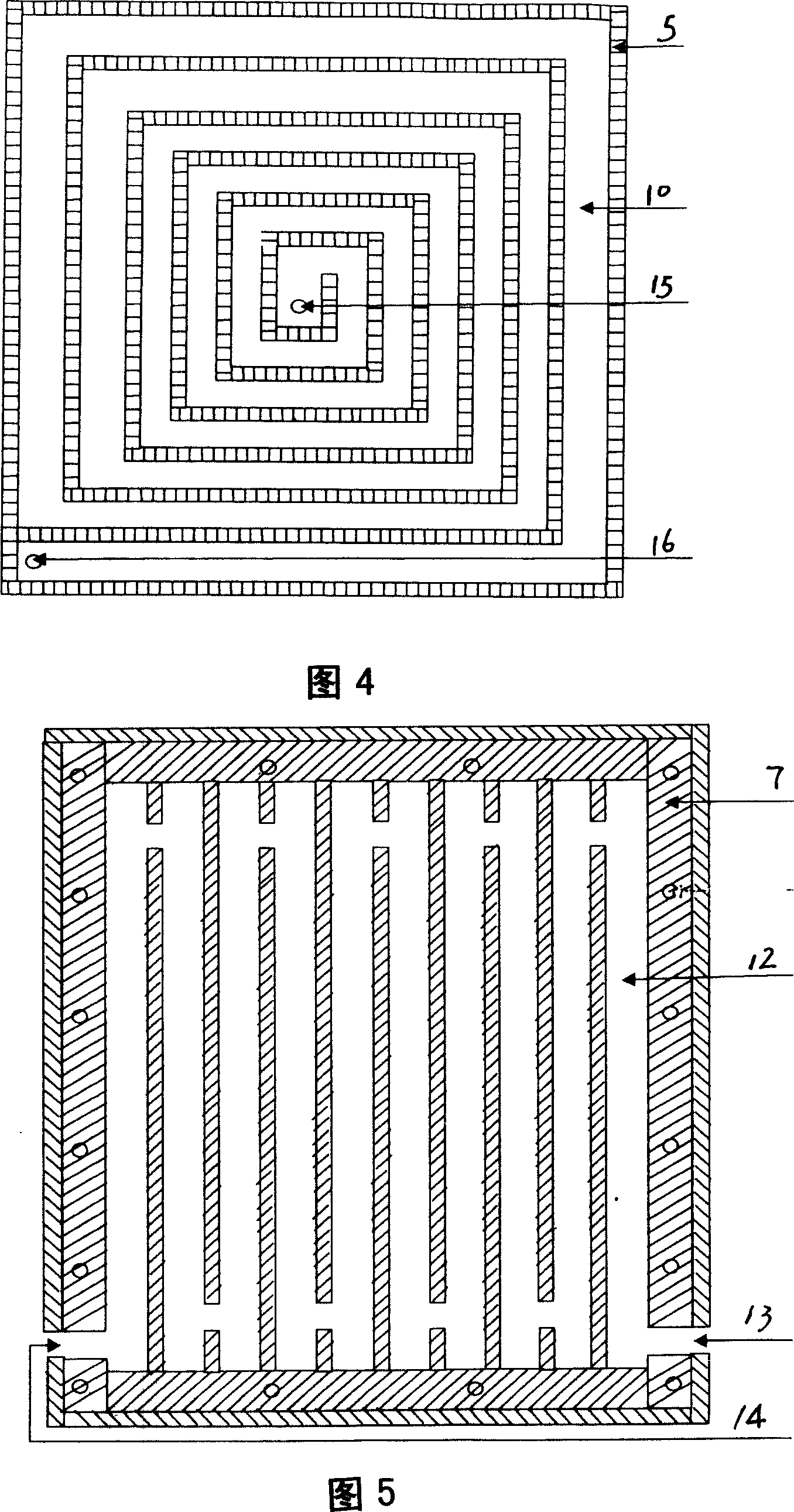

[0014] Embodiment 1, as shown in Figures 1, 2, 3, 4, 5, a water heater shell cover 8 is designed, the shell bottom plate 1 is fixedly connected to the base plate 2, the support column of the induction coil tray 5 components, and the other end of the support column is connected to the circuit substrate 2 And the induction coil tray assembly 5 is fixedly connected, the number of support columns is set according to the needs, the present invention selects 4 substrate support columns 3 and 3 induction coil tray assembly support columns 4, and the upper half of the induction coil tray is provided with an embedded induction coil 6 The circulation slot 10 is provided with an induction coil wire inlet hole 15 and a wire outlet hole 16 in the middle and sides, and a circulation cooling water channel 11 is provided in the lower half. The corresponding part of the inductance coil tray assembly is provided with a flat plate circulating water tank 7, which is provided with a folded water ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com