Laser detecting apparatus

A detector and laser technology, applied in the field of laser detectors, can solve problems such as low precision and slow speed, and achieve the effect of slow speed, fast speed and high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention can be used for the detection of various shafts. In this specific embodiment, a PCB micro-drill detector is taken as an example for illustration.

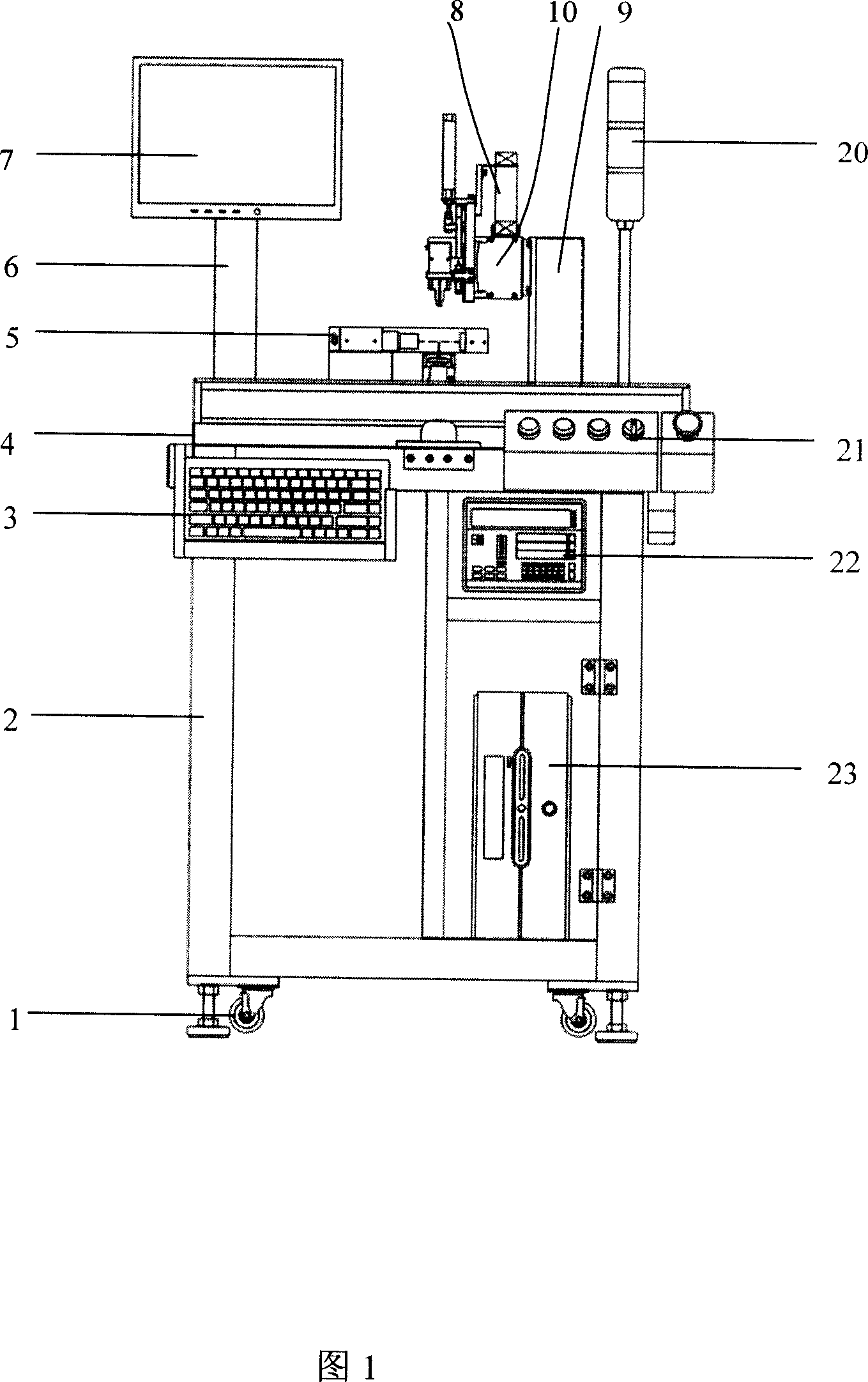

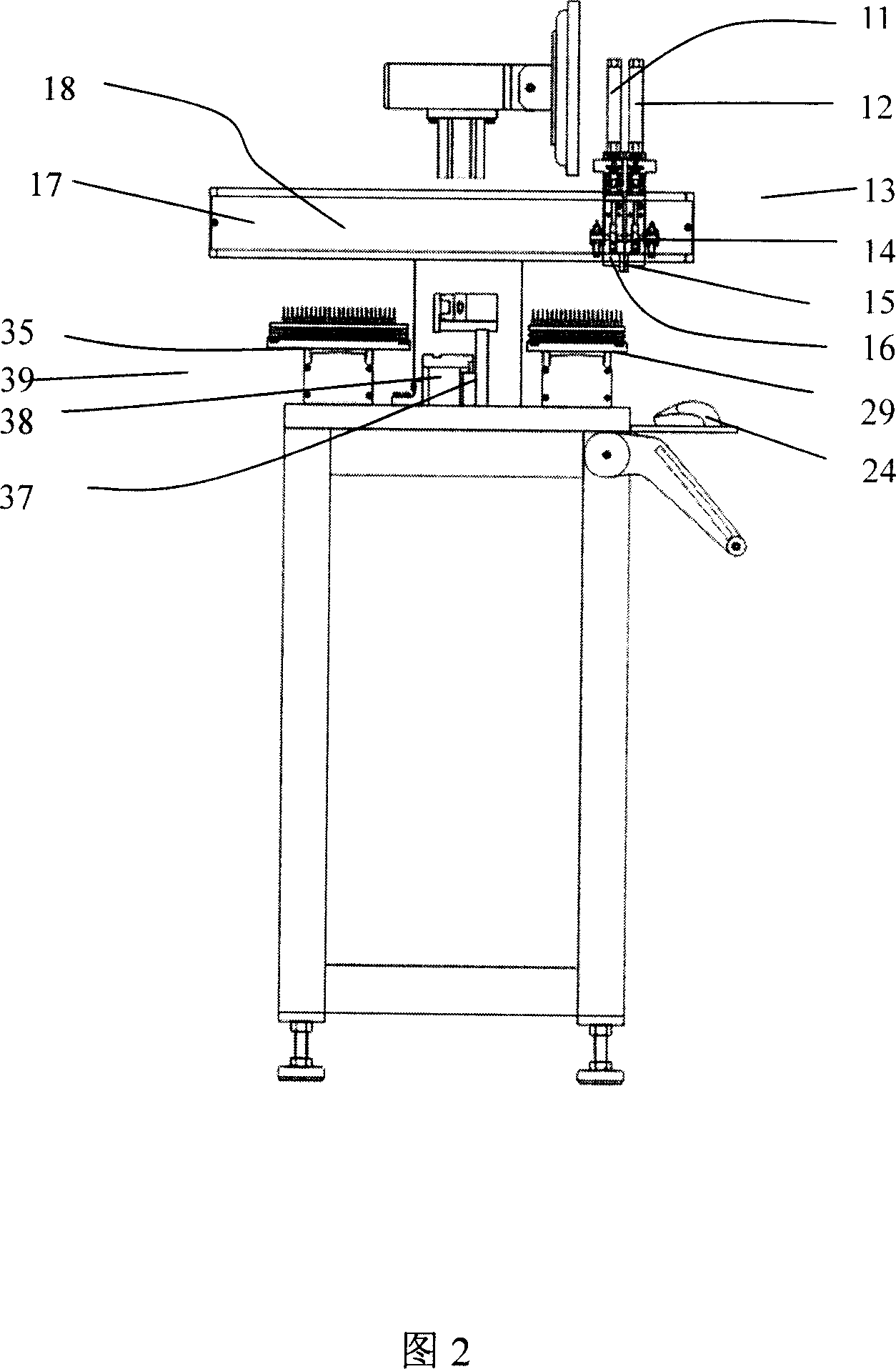

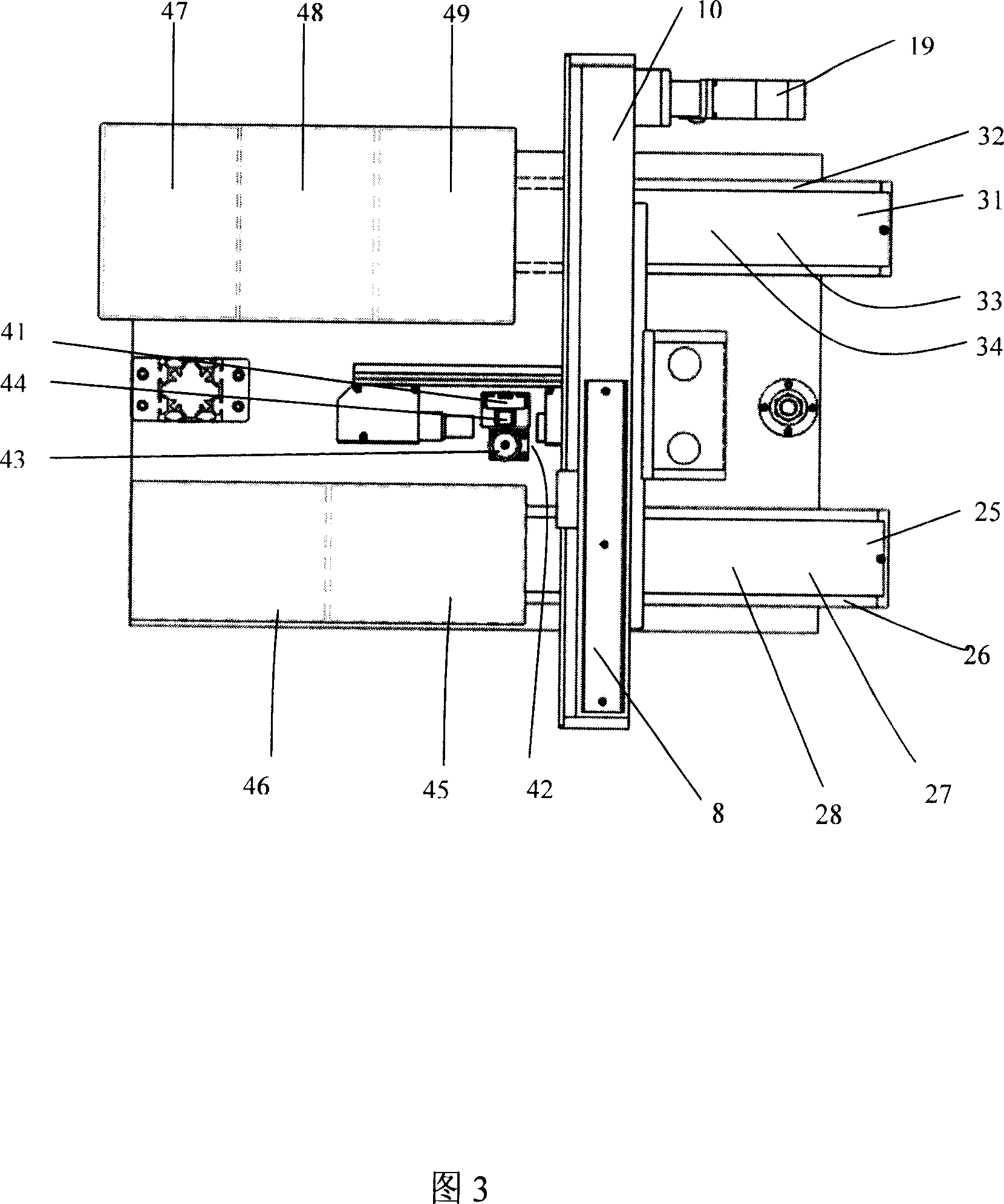

[0042] As shown in Fig. 1, Fig. 2, and Fig. 3, the laser microdrilling detector of the present embodiment is supported by the parts of the whole detection part and the whole control electric box by the body 2, and is arranged on the ground, by 4 casters and 4 feet cup 1 support; body 2 upper support plate 4 is provided with: a manipulator 8 that can slide freely on the main support plate 4 of the detection part, X1 axial feeding mechanism 25, X2 axial receiving mechanism 31, along the Z axis The non-contact laser head 5 that moves vertically and the display test data and the display 7 that is located on the display support frame 6 to display the software judgment result, the alarm indicator light 20 and the detection fixture when there is no material or abnormality.

[0043] In addition, the keyboard 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com