Automatic bubble counting system based on photoelectric technology

A technology of automatic counting and photoelectric technology, applied to counting mechanisms/items, by detecting the appearance of fluid at leak points, instruments, etc., it can solve the problems of manpower consumption, errors, and difficulty in accurate counting, and achieve simple structure and accurate counting , The effect of wide effective measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

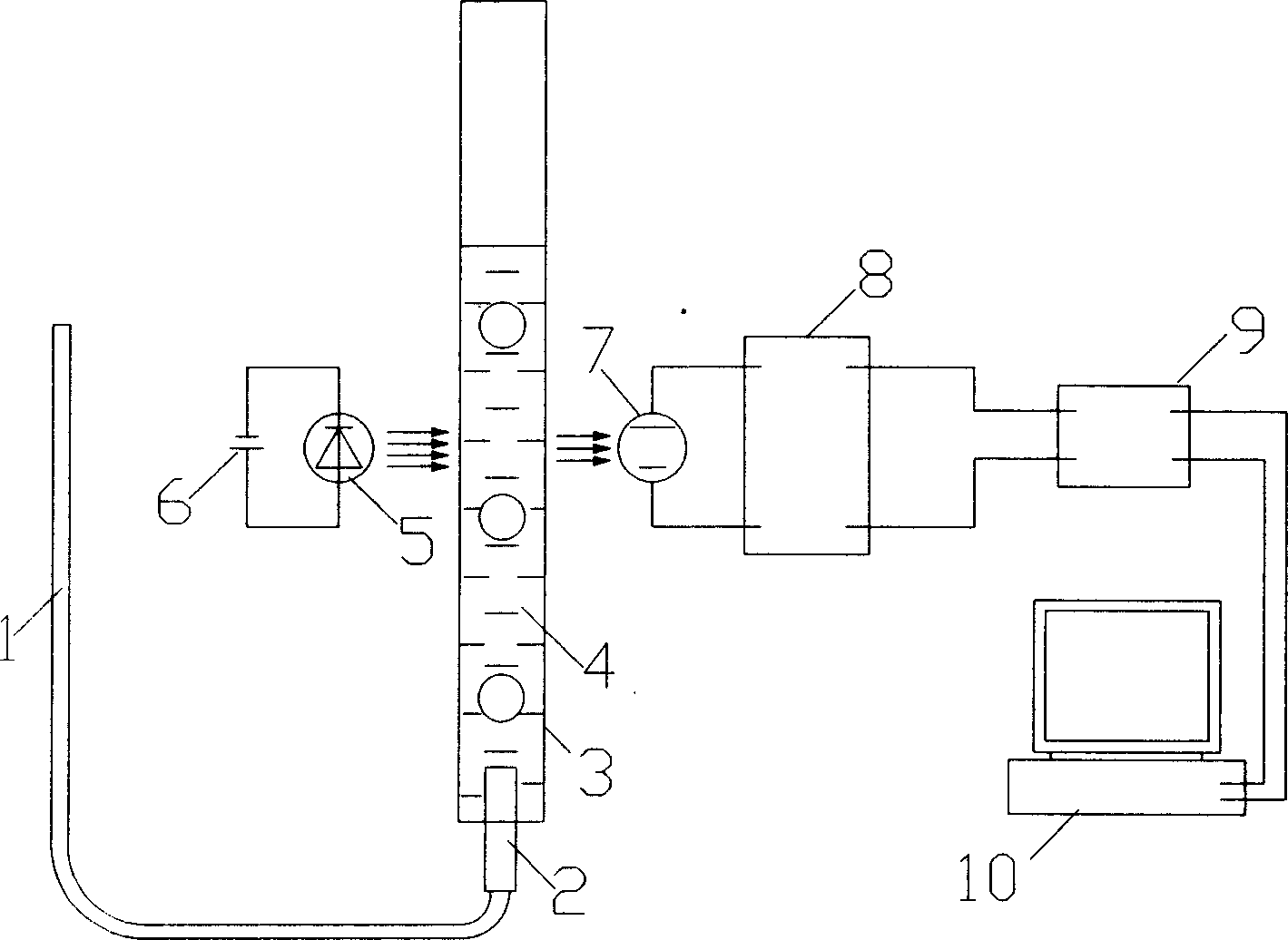

[0007] As shown in the figure, the bubble automatic counting system based on photoelectric technology includes an air inlet tube 1, a bubble tube 2, a glass measuring tube 3, a measuring agent 4, a light emitting diode 5, a DC constant voltage power supply 6, a silicon photocell 7, an amplifier circuit 8, Data acquisition card 9 and computer 10. The air inlet pipe is connected to the bottom of the glass measuring tube through the bubble tube. The two sides of the middle of the glass measuring tube are respectively equipped with light-emitting diodes and silicon photocells. The light-emitting diodes are connected to a DC constant voltage power supply. connect.

[0008] The gas inlet tube is used to lead the gas from the gas source to the bubble tube. One end of the bubble tube is connected to the inlet pipe, and the other end is inserted into the bottom of the glass measuring tube for bubbling. A certain amount of transparent liquid is filled in the glass measuring tube as th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap