Circuit breaker

A circuit breaker and moving contact technology, applied in the direction of protection switch operation/release mechanism, etc., can solve the problems of grid plate setting space and configuration block number limitation, circuit breaker breaking performance impact, stop pin breakage and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

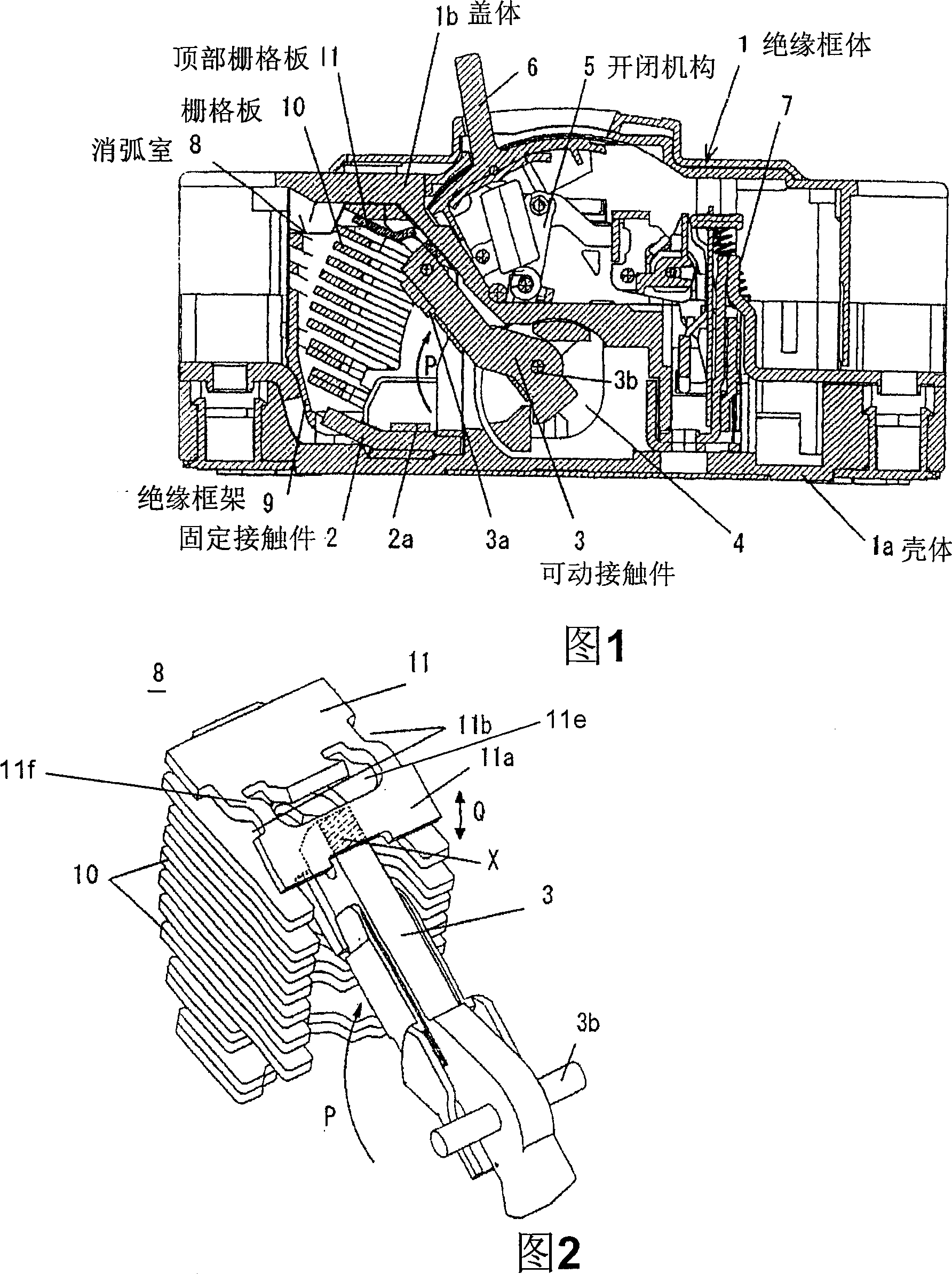

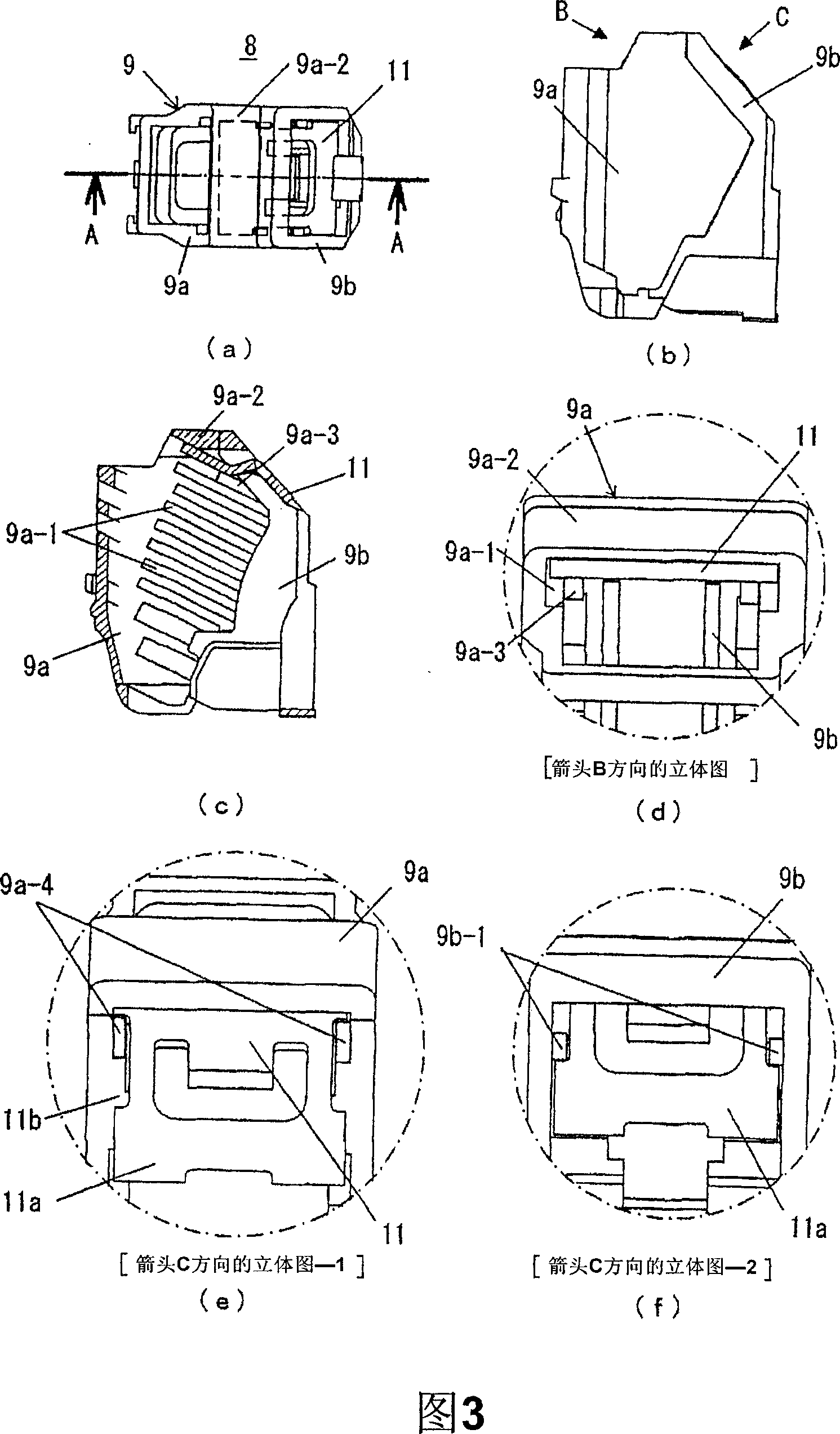

[0031] In Figs. 1 to 4, reference numeral 1 indicates the insulating frame (resin molded housing) of the circuit breaker composed of two separate structures of the housing 1a and the cover 1b, and the reference numeral 2 indicates the power supply side. The fixed contact piece of the main circuit terminal, the label 2a indicates the fixed contact, the label 3 indicates the rotary movable contact, the label 3a indicates the movable contact, and the label 3b indicates the rotation of the movable contact 3 The fulcrum, the symbol 4 represents the contact seat that holds the movable contact 3, the symbol 5 represents the toggle link type (togglering) opening and closing mechanism connected to the contact seat 4, and the symbol 6 represents the opening and closing mechanism. Close the operating handle, the number 7 indicates the thermal overcurrent drawing device, and the number 8 indicates the arc suppression chamber arranged in front of the movable contact 3 along the opening and ...

no. 2 example

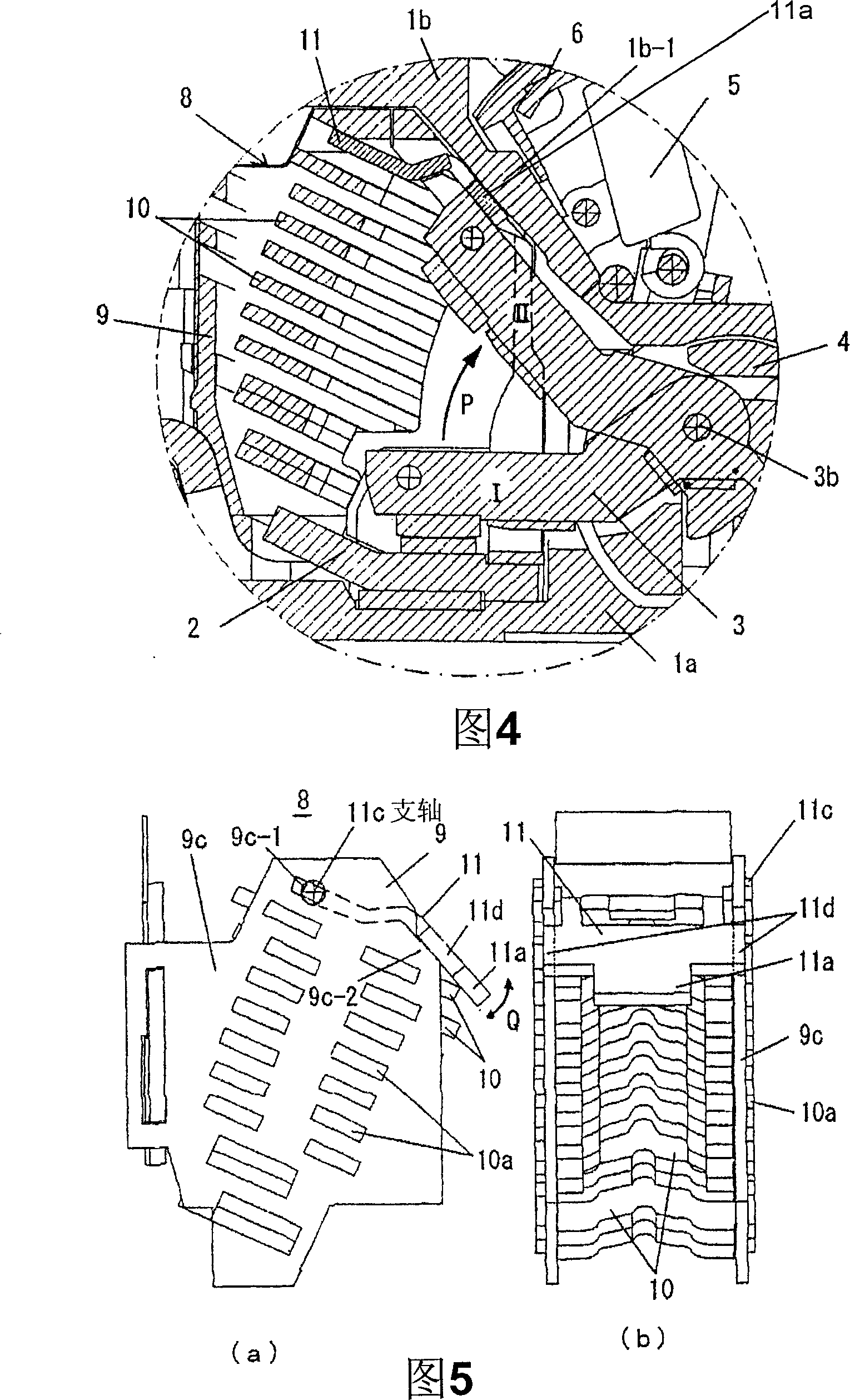

[0044] Next, an embodiment of the present invention will be described using Fig. 5(a) and (b). In this embodiment, for the top grid plate 11 held on the top of the insulating frame of the isolation chamber 8, a support shaft 11c protruding to the left and right sides is formed at the front end thereof, and a lateral support shaft 11c is formed at the rear side thereof. Engagement ears 11d whose edges protrude to the left and right sides. On the other hand, on the insulating frame side of the isolation chamber 8, on the top of the left and right side walls 9c, a bearing hole 9c-1 for inserting the above-mentioned support shaft 11c is formed through, and at the same time, the rear upper end surface of the side wall 9c is It is made as an inclined surface on which the ear portion 11d of the above-mentioned top grid plate 11 is sandwiched so that in this position, the collision portion 11a at the rear end protrudes from the back surface of the desolation chamber 8 . In addition, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com