Brake for towline of elevator

A rope brake, elevator traction technology, applied in the direction of the hoisting device, etc., can solve the problems of different force of the lock hook, uncertainty of the safety control of the lock hook, etc., to improve stability, overcome uncertain factors, and improve safety and reliability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

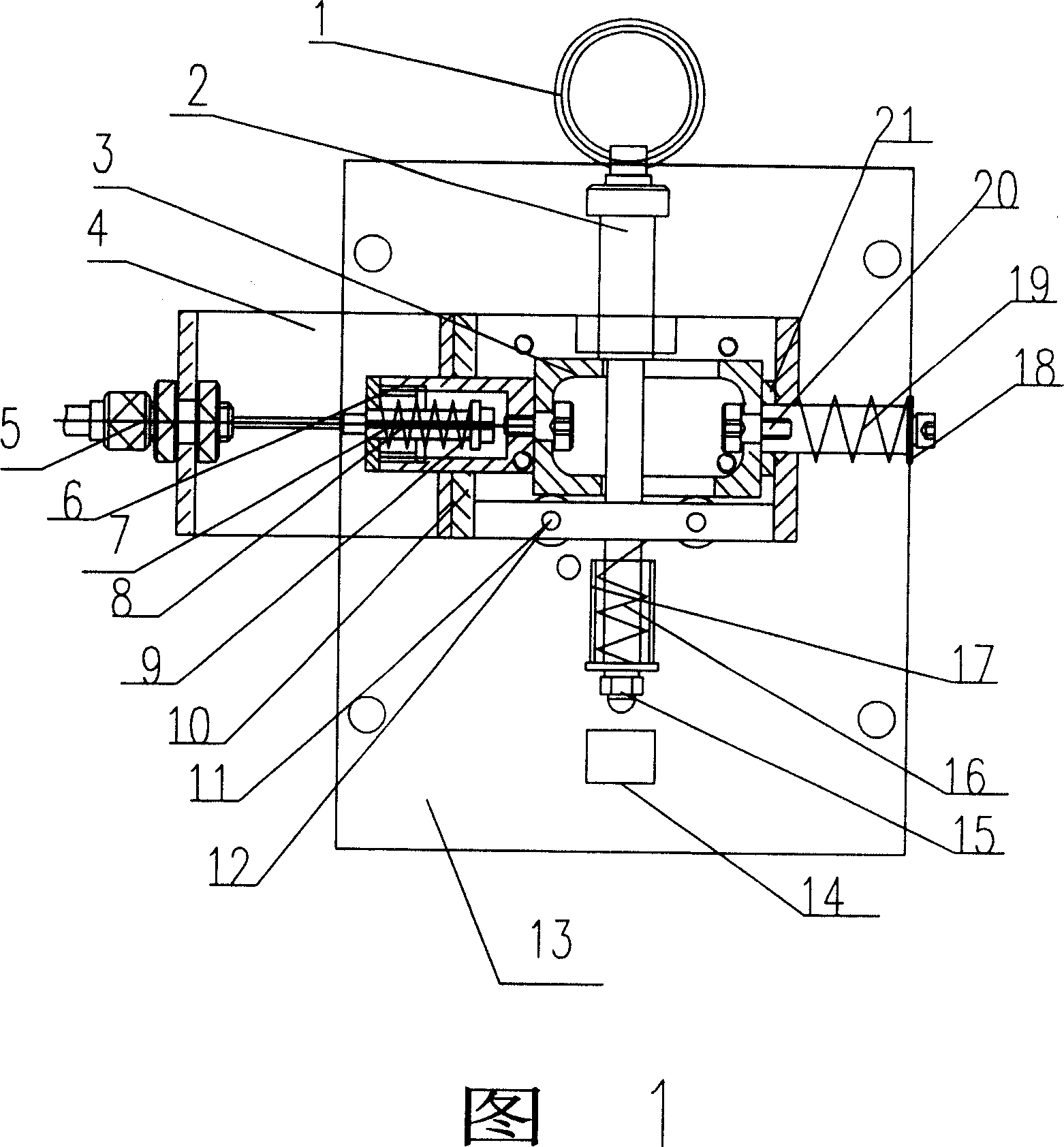

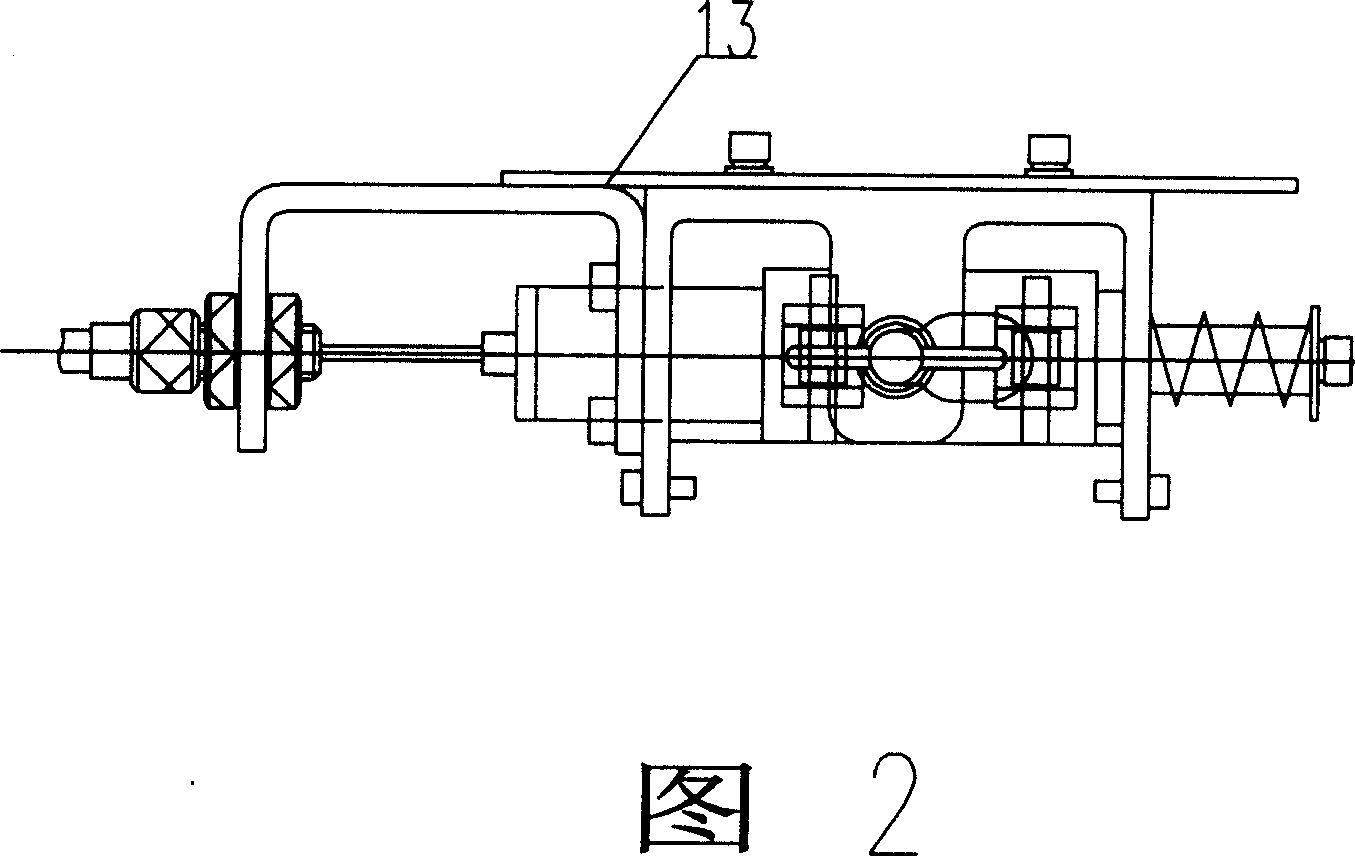

[0022] Embodiment 1: As shown in Figures 1, 2, and 5, the mechanical trigger mechanism is composed of an impact assembly 31, a brake line assembly 32, a reset assembly 33 and a bearing assembly 12. The impact assembly 31 is pressed against the bearing assembly 12 by the impact spring 16. The pull plate 3 on the top, the brake line assembly 32 is fixedly connected with the pull plate 3 on the bearing assembly 12 through screws, the brake wire 5 is driven by external force, pulls the pull plate 3 to slide to one end, and makes the impact assembly 31 lose its support and move downward. And under the action of the impact spring 16, the impact is realized, the reset assembly 33 is fixedly connected with the pull plate 3, and the pull plate 3 is pushed back by the reset spring 19.

[0023] The impact assembly 31 is composed of a pull ring 1, a guide post 2, a spacer 8, an impact spring 16, and a top screw 15. The pull ring 1 is rotatably installed on one end of the guide post 2, and ...

Embodiment 2

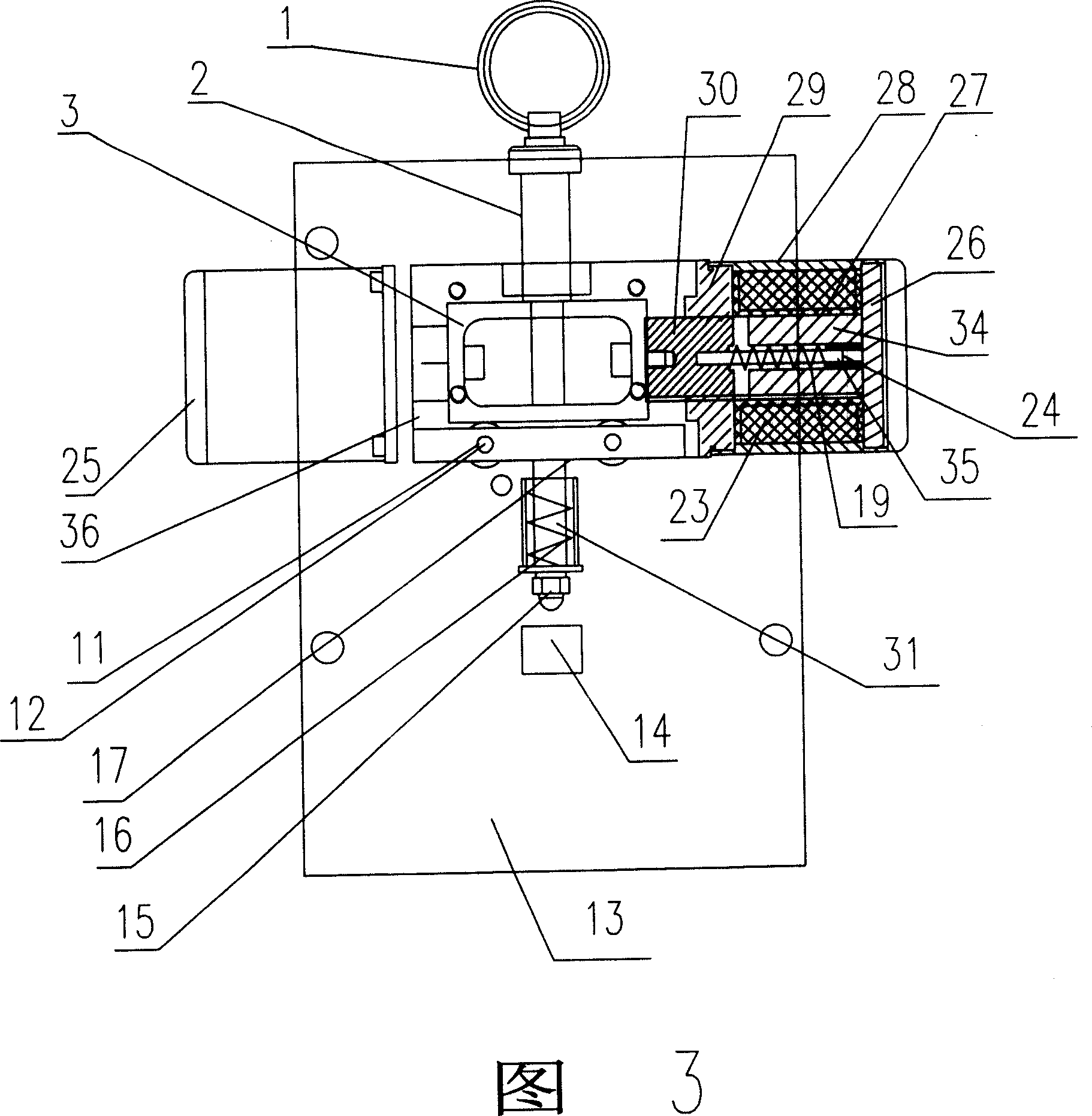

[0028] Embodiment 2: As shown in Figures 3, 4, and 6, the electromagnetic trigger mechanism is composed of an impact assembly 31, an electromagnet assembly 24, a wiring assembly 25, and a bearing assembly 12. The impact assembly 31 is pressed on the bearing assembly 12 by an impact spring. The pull plate 3 is supported by the pull plate 3, and the armature 30 of the electromagnet assembly 24 is fixedly connected with the pull plate 3 through screws. When the electromagnet 34 generates electromagnetic force in the energized state, the electromagnetic force makes the pull plate 3 move to one end , open the lock hook 14 to realize impact.

[0029] The impact assembly 31 is composed of a pull ring 1, a guide post 2, a spacer 17, an impact spring 16, and a top screw 15. The pull ring 1 is rotatably installed on one end of the guide post 2, and the guide post 2 extends into the shock spring 16, and the spacer 17 is sleeved outside the shock spring 16, and the spacer 17 and the guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com