Iterative control method for bottle cap image acquisition

An image acquisition and iterative control technology, applied in the field of control, can solve the problems of inaccurate bottle cap image acquisition and the sensing error of a camera mounted boom sensor, and achieve the effect of overcoming uncertain interference and accurate photographing acquisition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in more detail and complete below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention.

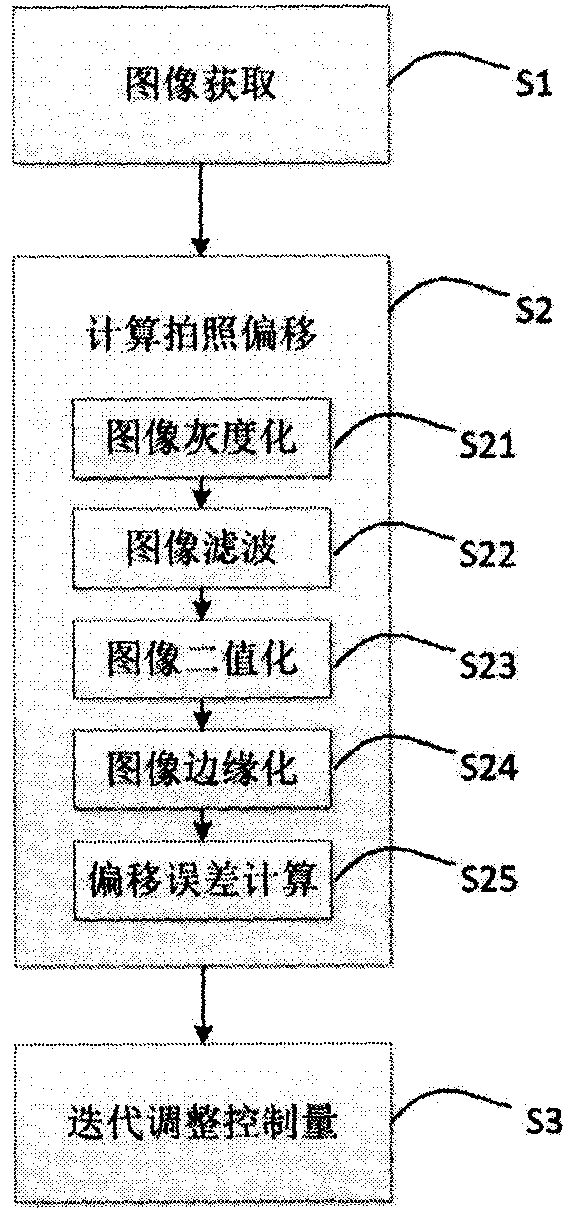

[0013] refer to figure 1 , an iterative control method for bottle cap image acquisition according to an embodiment of the present invention, the method comprising:

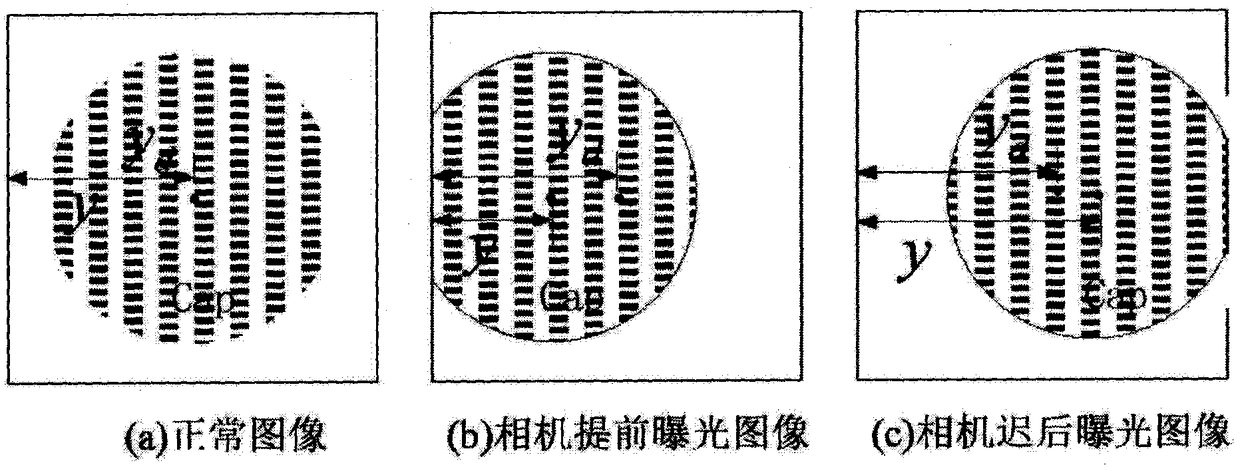

[0014] S1 image acquisition, when the bottle cap moves to the infrared receiver, the infrared receiver is triggered and sends an instruction to the control unit, the control unit prolongs the appropriate length of time, and then sends an instruction to trigger the exposure of the camera, and at the same time trigger the flash of the light source to acquire the image.

[0015] S2 calculates the photographing offset, performs image processing on the acquired bottle cap image, obtains the distance between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com