Construction machine

A technology for construction machinery and engines, applied in construction, earthmoving machines/shovels, etc., can solve problems such as unfavorable work efficiency, disturbing operators, dangers, etc., to improve safety and work efficiency, improve work efficiency, eliminate underpowered effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

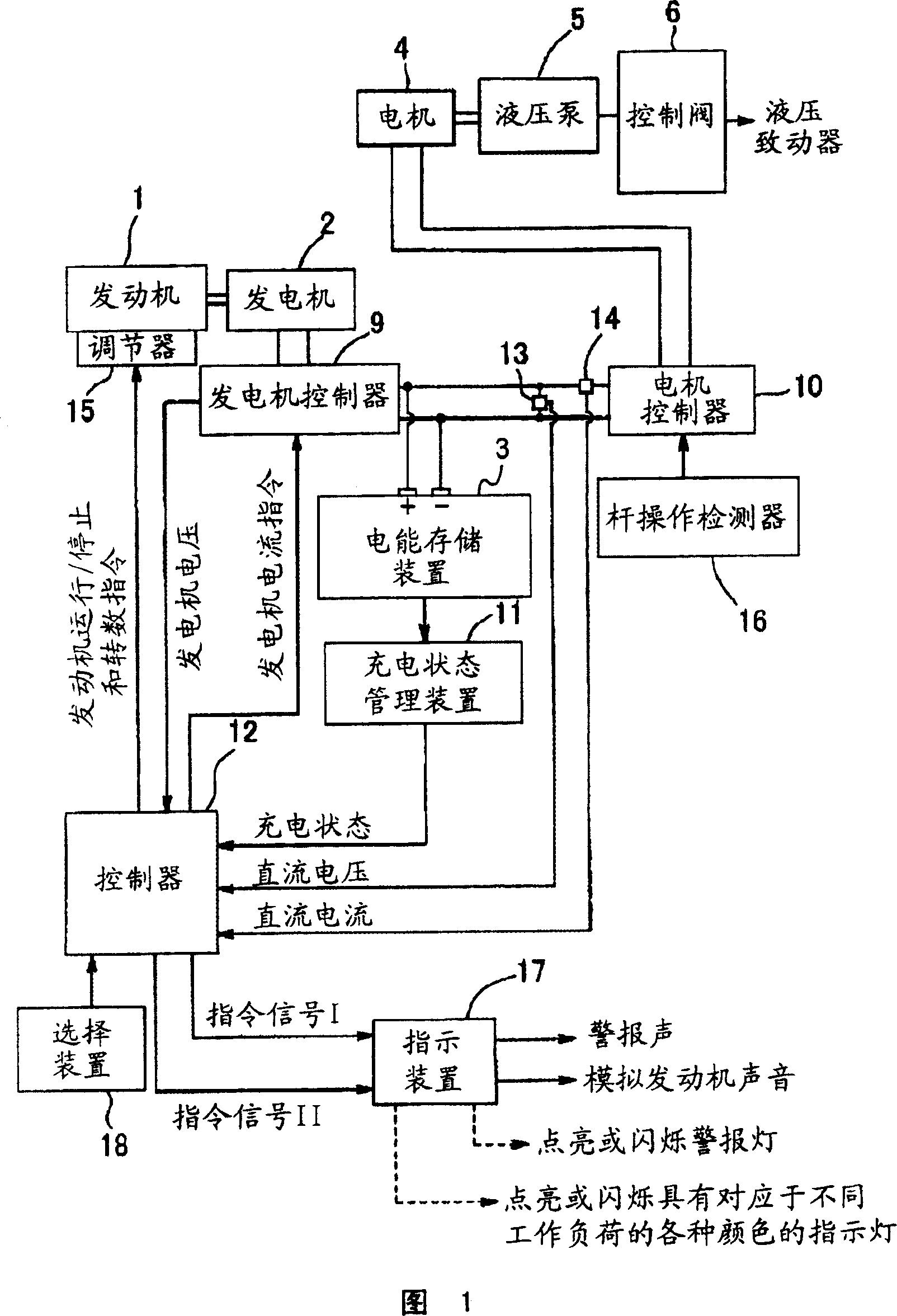

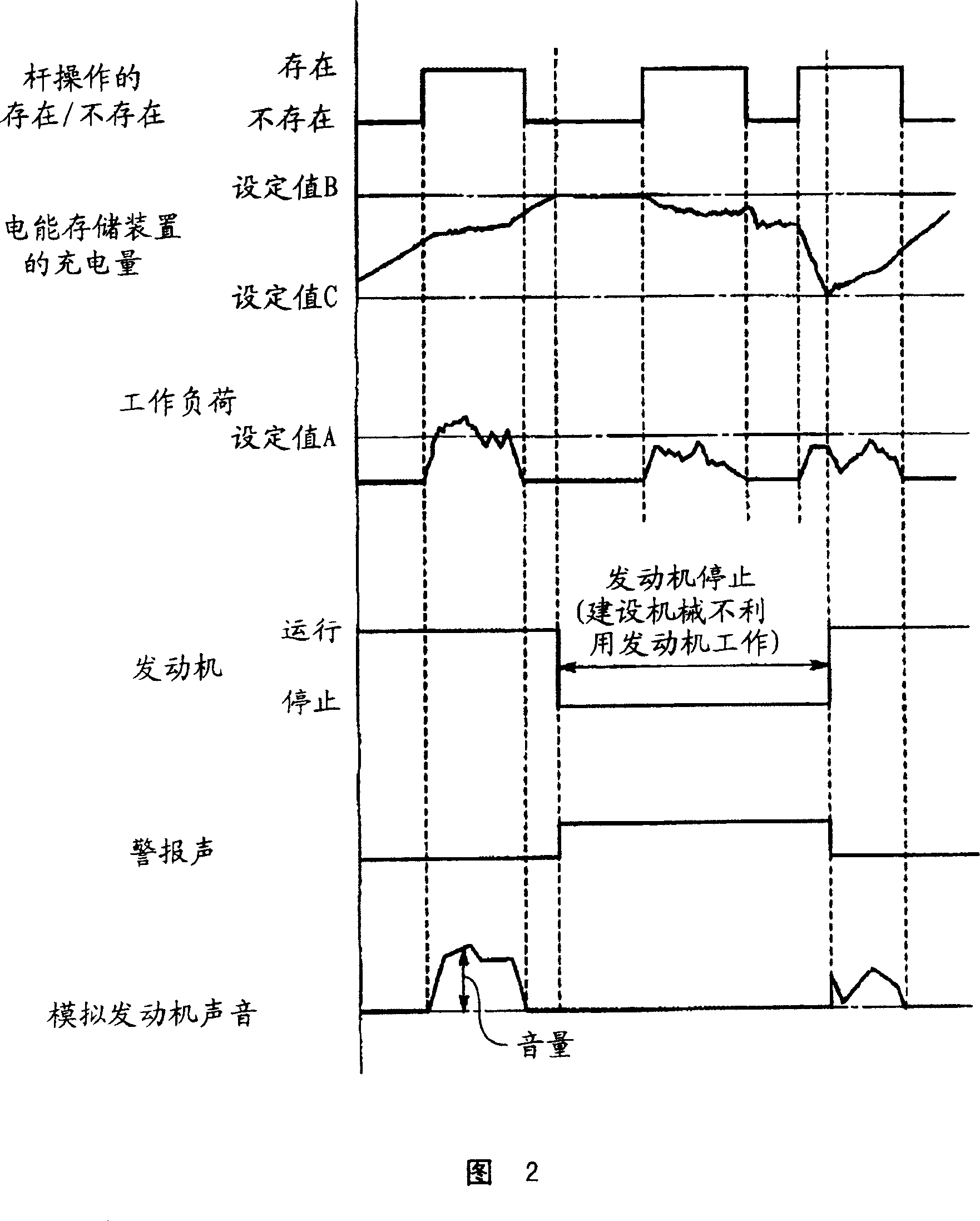

[0049] First embodiment (refer to Fig. 1 and 2)

[0050] The construction machine of the first embodiment is a tandem type.

[0051] In the first embodiment and other embodiments of the present invention (to be described later), the same parts as those in FIGS. 7 and 8 are denoted by the same reference numerals, and thus their descriptions are omitted to avoid repetition.

[0052] As shown in FIG. 1 , in a series system, the output of the generator 2 is transmitted to the electrical energy storage device 3 through the generator controller 9 .

[0053] In addition, the outputs of the generator 2 and the electric energy storage device 3 are transmitted to the motor 4 through the motor controller 10 , whereby the motor 4 rotates to drive the hydraulic pump 5 .

[0054] The charging amount of the electric energy storage device 3 is detected by the charging state management device 11 and transmitted to the controller 12 .

[0055] In addition to the amount of charge input to the ...

no. 2 example

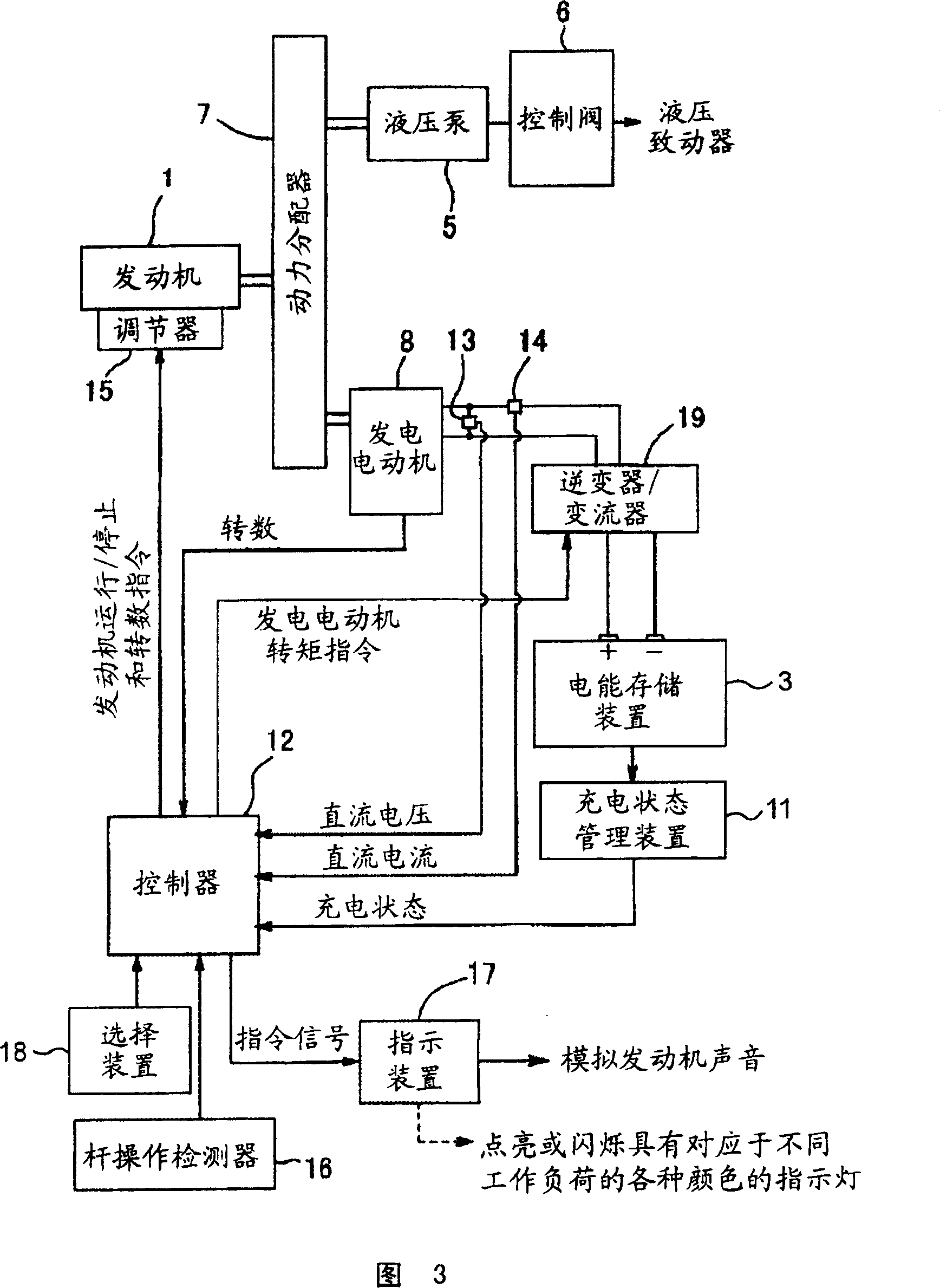

[0071] Second embodiment (refer to Fig. 3)

[0072] The construction machines of the second embodiment are of the parallel type. Only the differences between the second embodiment and the first embodiment are described here.

[0073] In the parallel system, the electric energy storage device 3 is connected to the generator motor 8 through the inverter / converter 19, and the charging / discharging of the electric energy storage device 3 is controlled in response to the shortage / excess of the generator output of the generator motor 8.

[0074] The inverter / converter 19 switches between the generator function and the motor function of the generator motor 8 based on instructions from the controller 12, and controls the generated output (the number of revolutions of the generator motor 8) and the rotation speed of the generator motor 8. moment control, and so on.

[0075] As described above, in the parallel system, the engine 1 is always on during operation, and there is no operatin...

no. 3 example

[0086] Third embodiment (refer to FIG. 4 )

[0087] Fig. 4 is a block diagram showing the constitution of a driving system and a control system of a tandem construction machine according to a third embodiment of the present invention. The same parts in FIG. 4 as those in FIG. 7 are denoted by the same reference numerals, and their descriptions are omitted to avoid repetition.

[0088] As shown in FIG. 4 , the output of the generator 2 is transmitted to the electrical energy storage device 3 through a generator controller 9 .

[0089] Also, the output of the generator 2 and the electric energy storage device 3 is transmitted to the motor 4 through the motor controller 10 , whereby the motor 4 rotates to drive the hydraulic pump 5 .

[0090] The charging state management device 11 detects the charging amount of the electric energy storage device 3 and transmits the detection result to the controller 12 .

[0091] In addition to the amount of charge, the input to the controller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com