High efficient cathode assembly

A cathode assembly and cathode technology, applied in the field of cathode assembly and high-efficiency cathode assembly, can solve the problems of high working temperature and high heating power, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

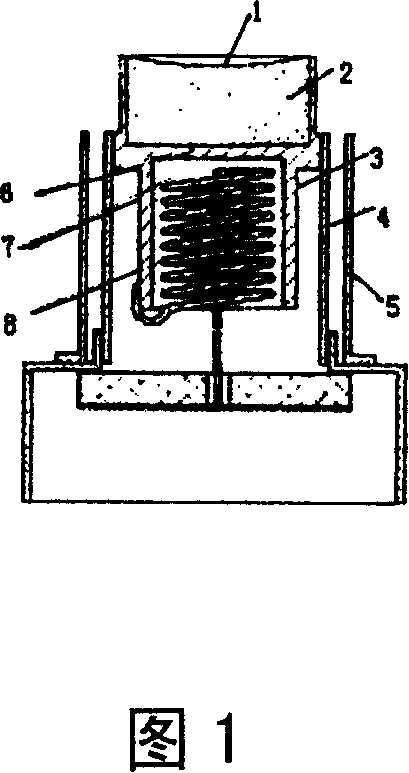

[0010] The structure of the cathode assembly is shown in Figure 1, which is basically a conventional structure, consisting of a cathode, a cathode cylinder 3, a cathode support cylinder 4, a cathode heat shield 5, a baffle 6, and a heater 8. The cathode includes a cathode surface 1 and a cathode base 2 Alumina 7 is filled between the cathode cylinder 3 and the heater 8, and a cylindrical cathode heat shield 5 is provided on the periphery of the cathode support cylinder 4, so that the cathode support cylinder 4 and the cathode heat shield 5 form a two-layer heat shield structure.

[0011] The heater 8 adopts a thermal subassembly structure, and the thermal subassembly is to bury the heating body (usually W wire or W-Re wire) in an insulating medium (usually Al 2 o 3 ), thus on the one hand avoiding the thermal short circuit caused by vibration, etc., and improving the reliability of the thermal 8, on the other hand, the heating of the cathode by the thermal 8 is changed from he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com