Centrifugally activated bobbin coupling

A coupling and bobbin technology, applied in textiles and papermaking, etc., can solve the problems of damage, wear, high cost of manufacturing and assembly, and achieve the effects of easy manufacturing, low cost, and strong wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

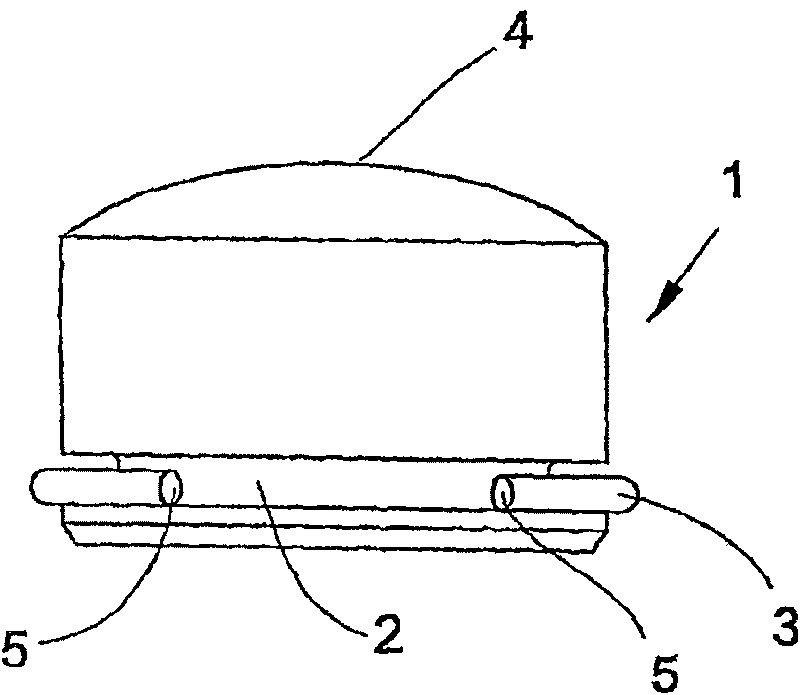

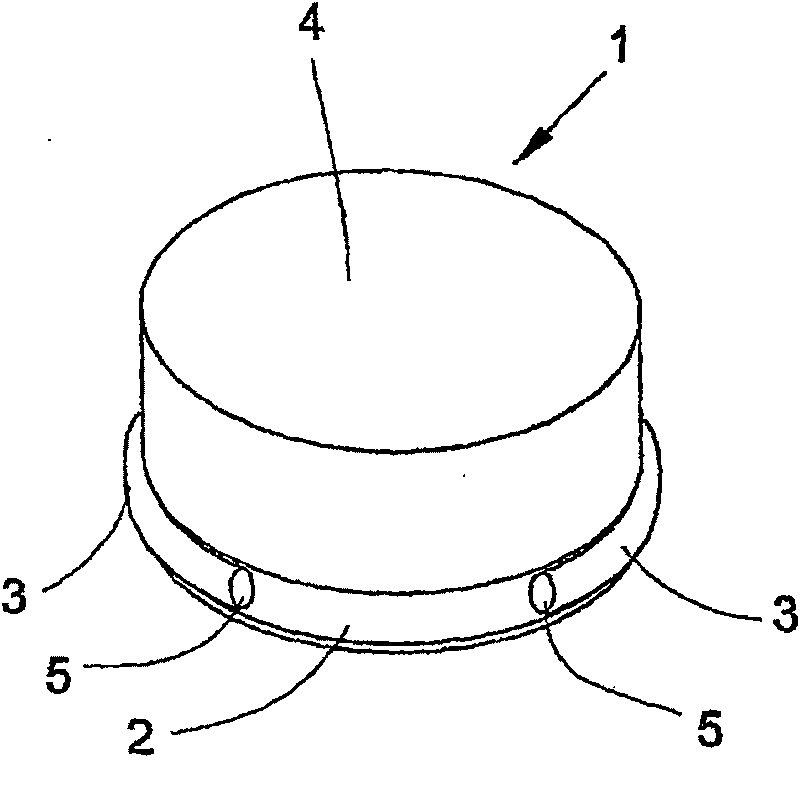

[0025] figure 1 The shown pre-assembled module comprises a coupling button 1 as well as a spring element 3. The coupling button 1 has a groove 2 in which the spring element 3 formed as a split ring is placed. The coupling button 1 is located opposite the groove 2. Convex curved joint surface at the end 4.

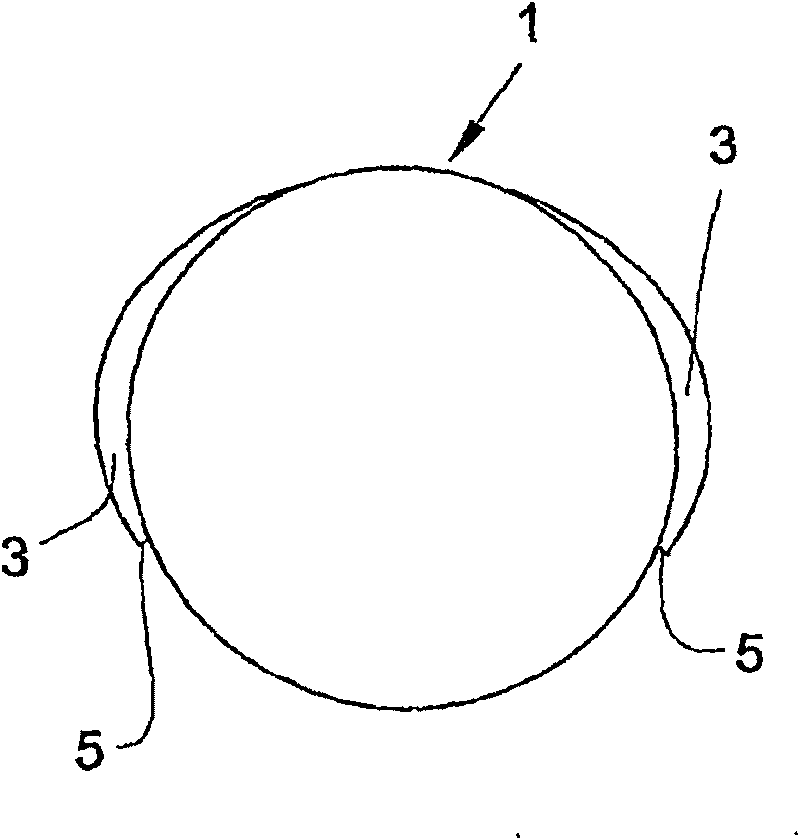

[0026] exist figure 2 The oval shape of the ring can be seen in the plan view of the coupling button 1 . The ring is open between free ends 5 which are completely separated from each other. Such as figure 2 view of and image 3 The free end 5 of the ring is located in the groove 2 as shown in the perspective view of . The part of the ring opposite the open part is completely in the groove 2 . The shape of the ring together with the groove 2 results in a firm hold on the coupling button 1 .

[0027] Figure 4 The coupling button 1 is shown during insertion into the hole 6 of the spindle 7 . To this end, the pre-assembled module comprising the coupling button 1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com