Variable focus lens

A focus lens and lens technology, applied in the direction of lenses, optics, instruments, etc., can solve the problems of high voltage and impracticality, and achieve the effect of large zoom factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

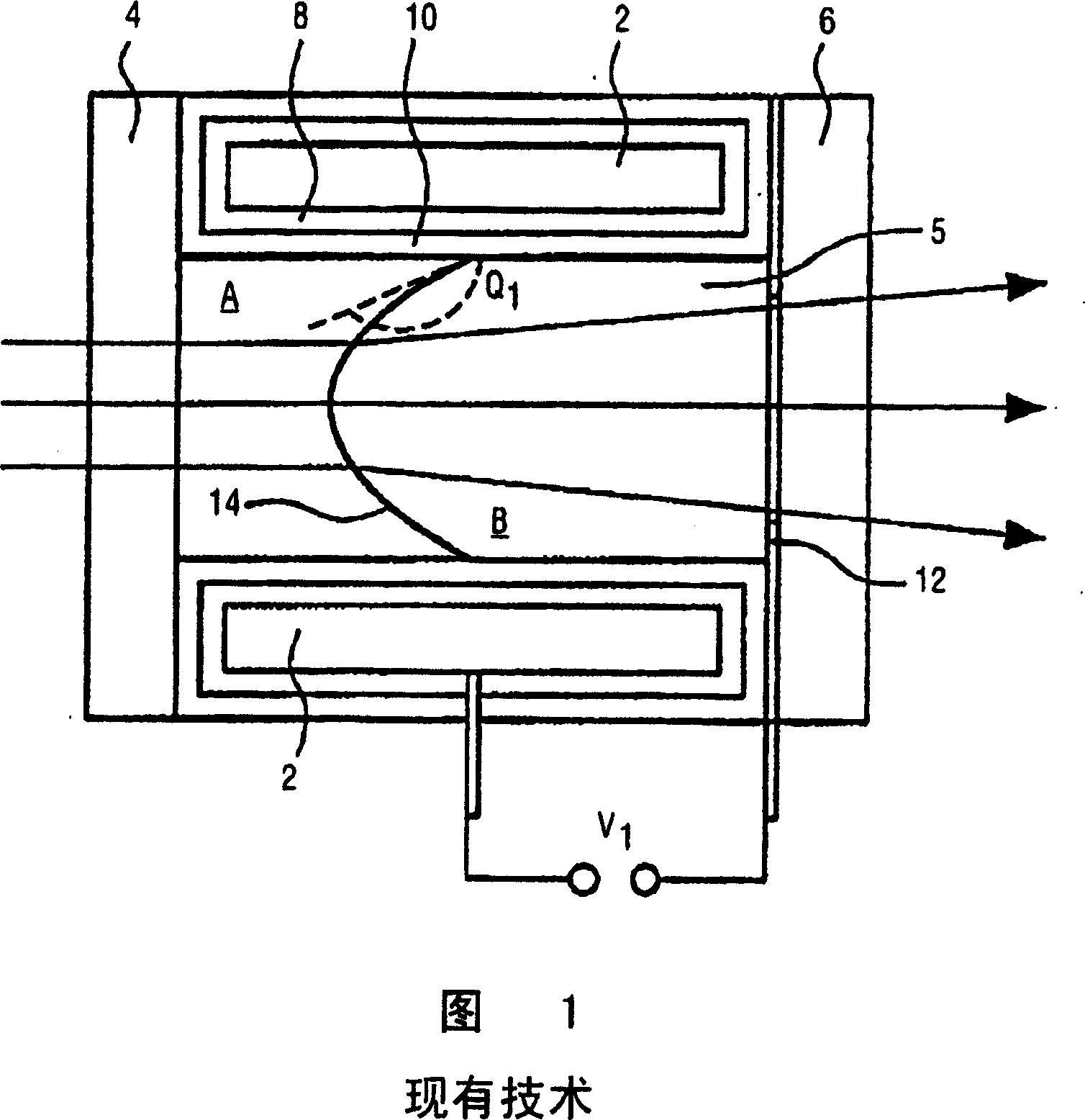

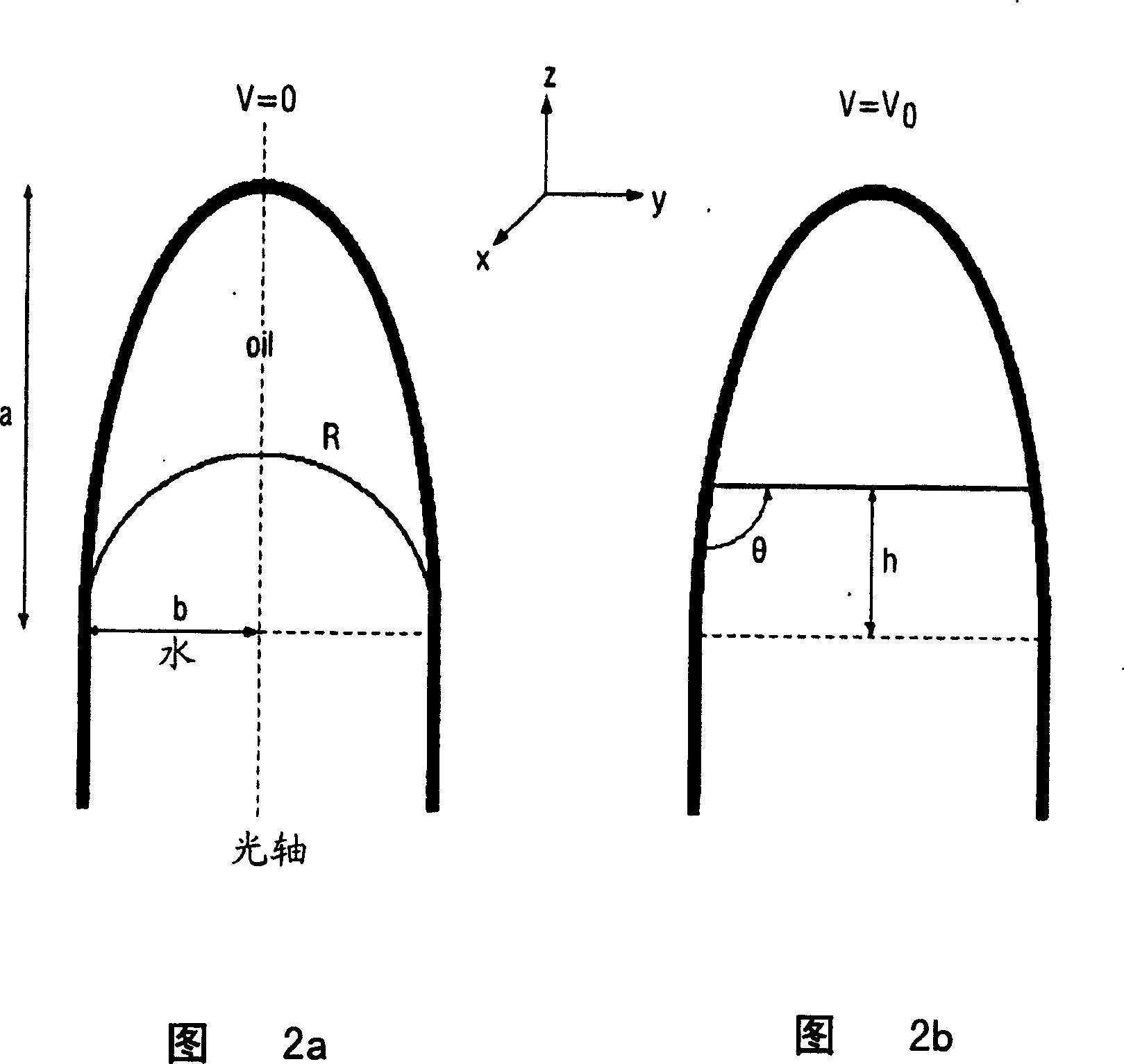

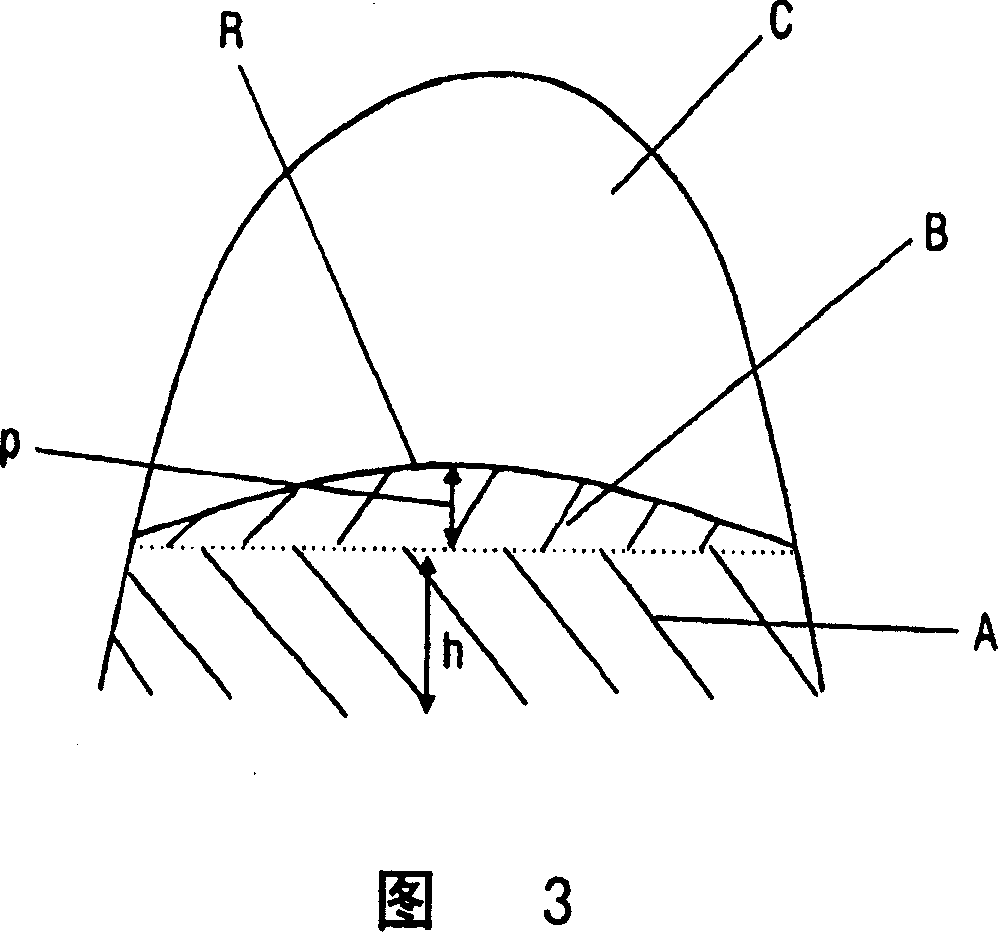

[0022] In order to understand the operation of embodiments of the present invention, it is instructive to review the operation of the prior art electrowetting lens shown in FIG. 1 . Such lenses are described in detail in WO 03 / 069380, and reference is made to this publication for a general understanding of the operation and construction of such lenses.

[0023] For the purposes of the present invention, the following brief description will suffice.

[0024] The lens shown in Figure 1 comprises a cylindrical first electrode 2 forming a capillary, which is sealed by means of a transparent front group 4 and a transparent rear group 6, forming a fluid chamber 5 containing two fluids. Electrode 2 may be a conductive coating applied to the inner wall of the tube.

[0025] Two fluids are composed of two immiscible liquids, namely an electrically insulating first liquid A (such as silicone oil or alkane, referred to herein as "oil") and a conductive second liquid B (such as containin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com