Sweeping apparatus workable at condition of electrification in high voltage

A cleaning device and high-voltage electrified technology, which is applied in the direction of cable installation device, cable installation, electrical components, etc., can solve the problems such as cleaning cannot be realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

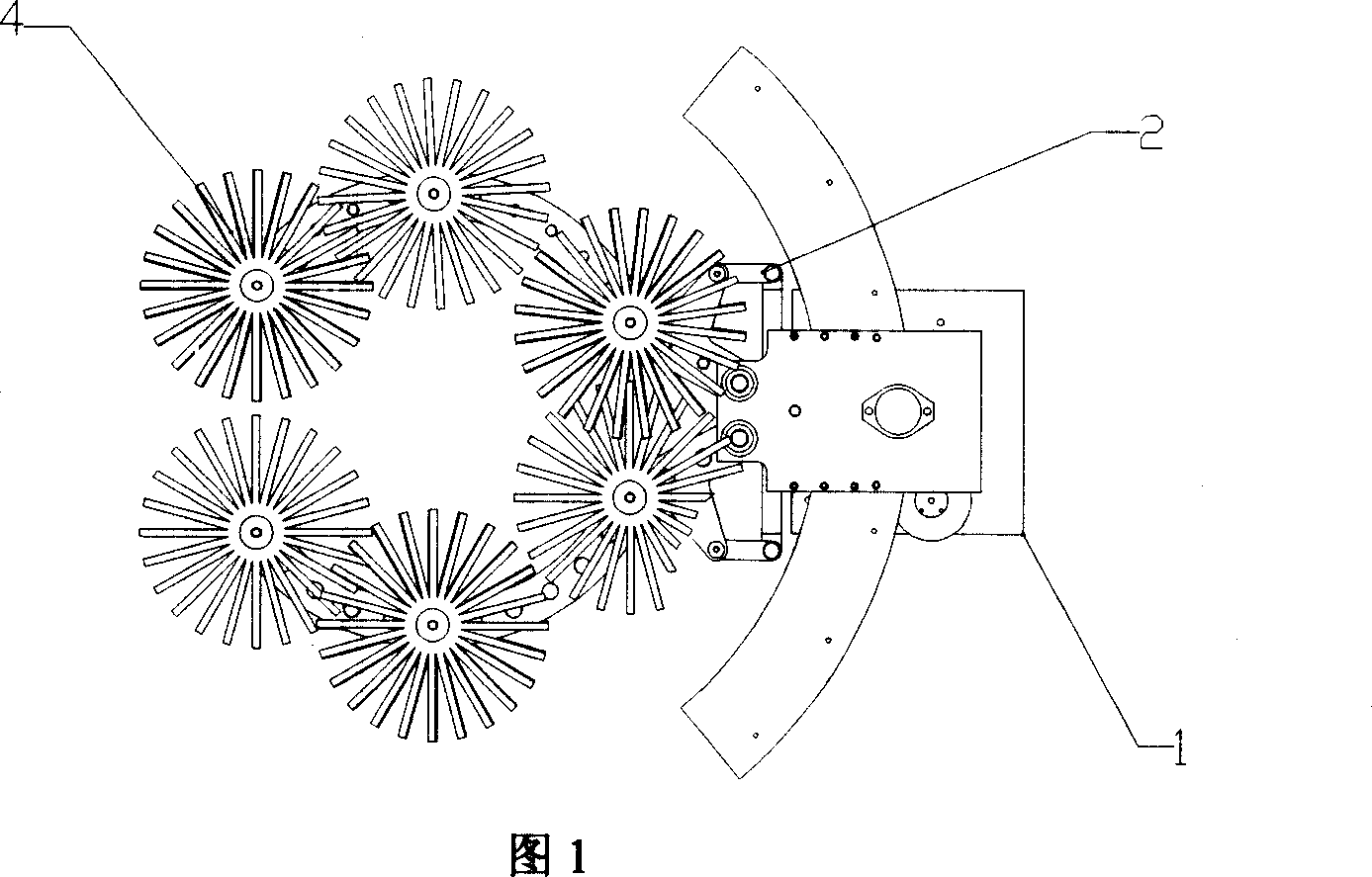

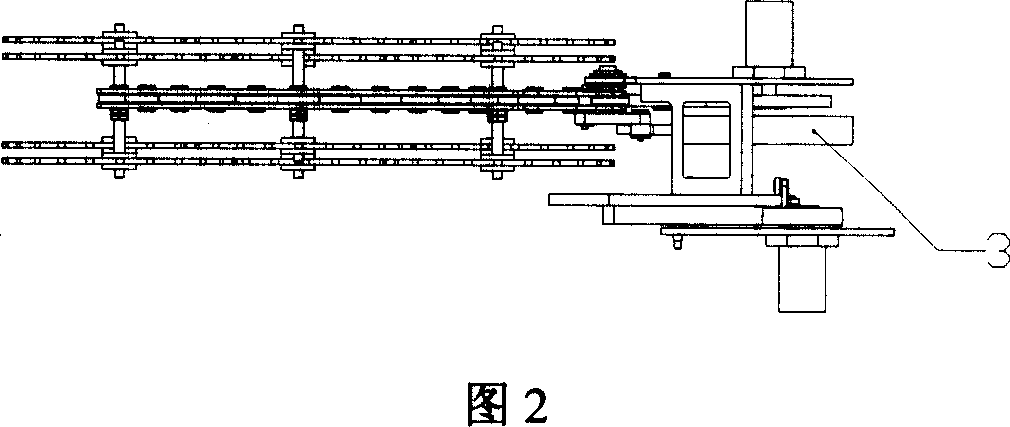

[0018] As shown in Figures 1 and 2, this embodiment includes: a rotary table 1, an opening and closing push rod 2, a linear oil cylinder 3, and a cleaning arm 4. The linear oil cylinder 3 is arranged on the cleaning arm 4, and one end of the opening and closing push rod 2 is connected to the linear oil cylinder 3 are connected, one end is connected with the cleaning arm 4, the linear cylinder 3 drives the opening and closing push rod 2, and the opening and closing push rod 2 drives the cleaning arm 4 to rotate, and drives the hydraulic motor of the rotary table 1 to transmit the rotating power to the connected brush , the brush rotates to clean the dust on the porcelain bottle.

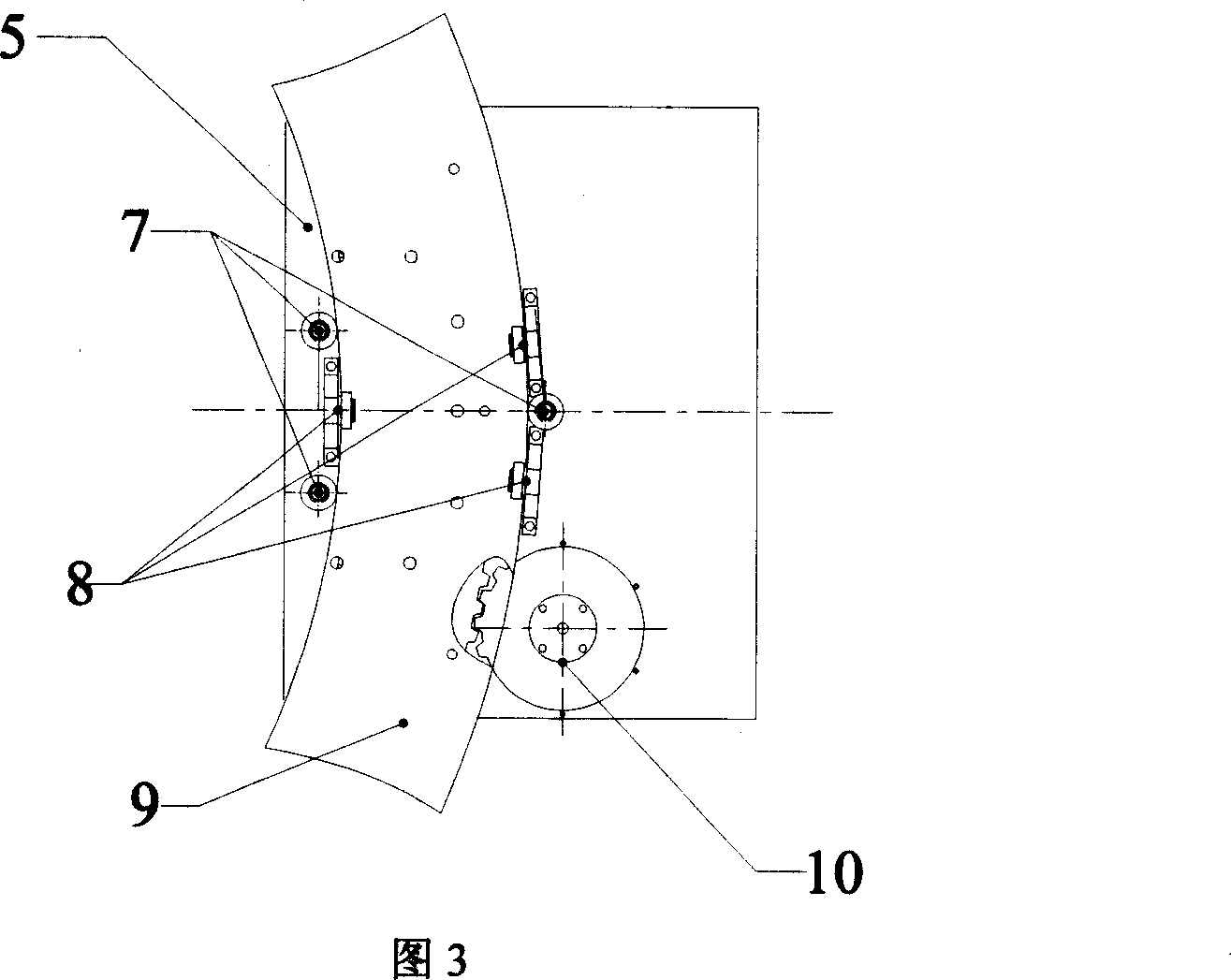

[0019] As shown in FIGS. 3 and 4 , the rotary table 1 includes: a bottom plate 5 , a lower bearing support 6 , a side bearing support 7 , an upper pressure bearing 8 , a rotating platform 9 , and a power transmission mechanism 10 .

[0020] Base plate 5, as the support of the whole device;

[0021] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com