Adjustable clearance guide rail of pre stressed stand in large scale forging pump press

A hydraulic press and prestressing technology, applied in the direction of presses, forging/pressing/hammering machines, forging/pressing/hammer devices, etc., can solve the problems of reduced reliability and service life of columns, large thermal deformation of components, and decreased accuracy of hydraulic presses, etc. problem, to achieve the effect of improving reliability and anti-eccentric moment ability, high dimensional and shape accuracy, and improving fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

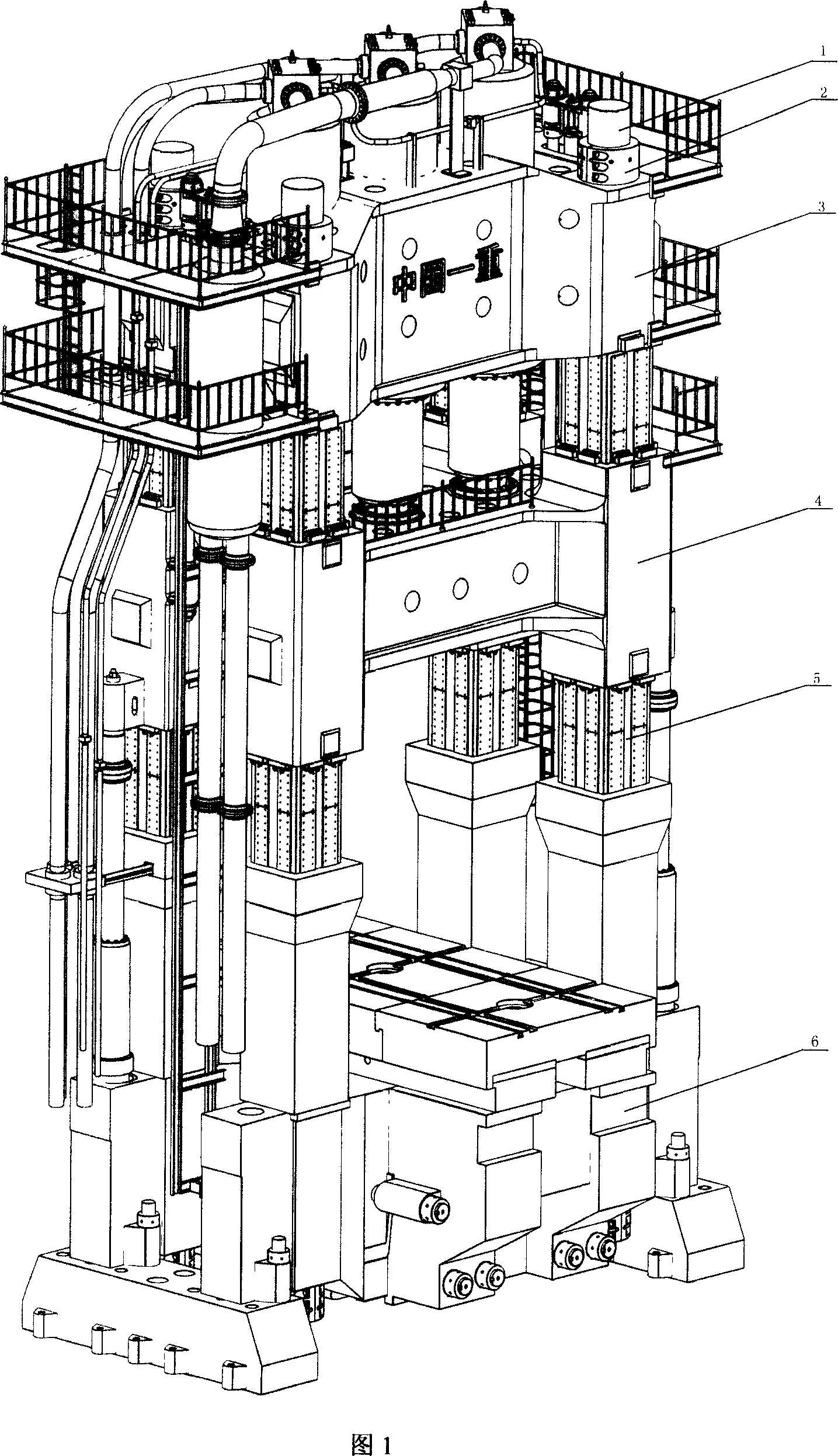

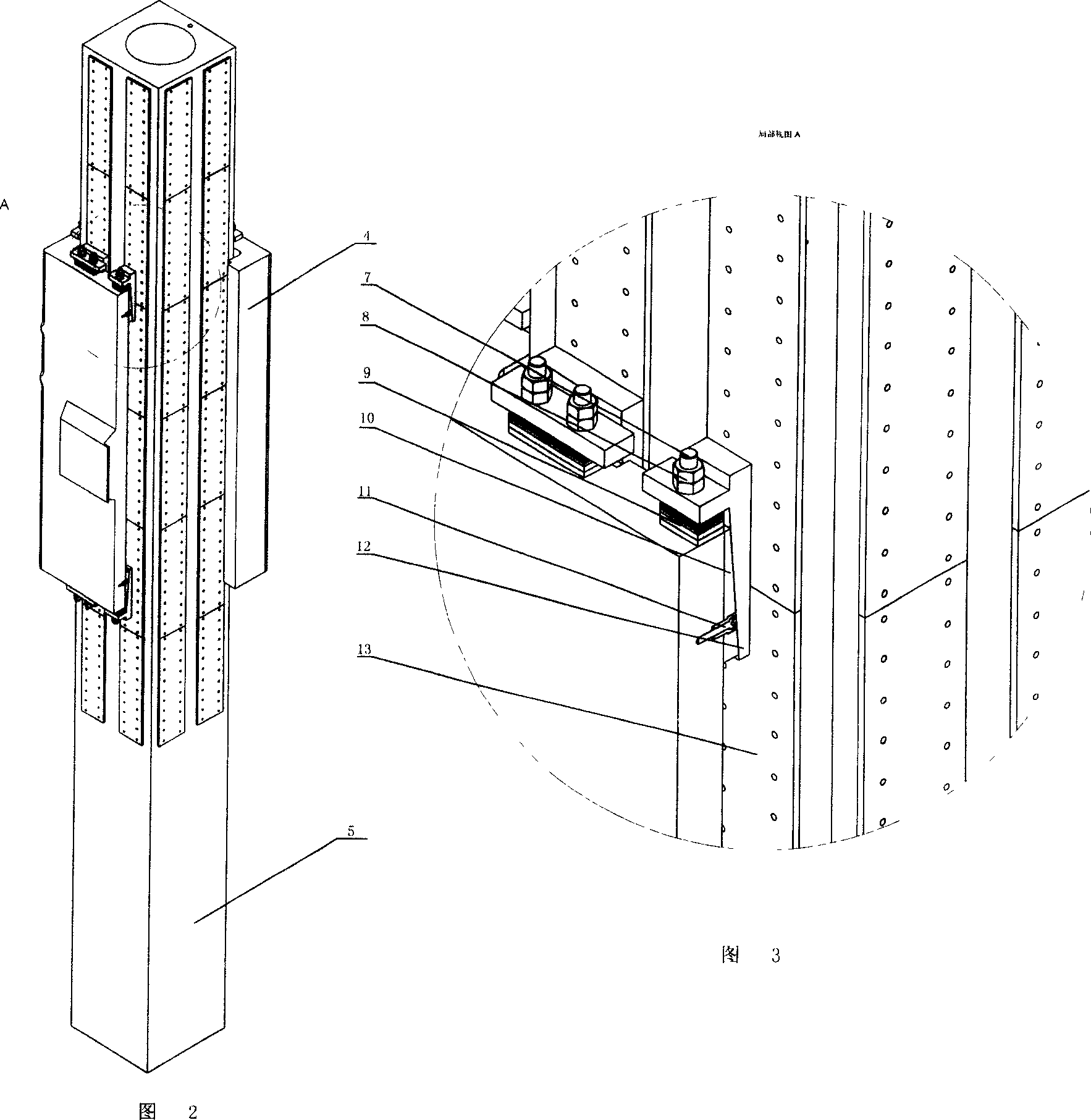

[0011] In the embodiment shown in Fig. 1-Fig. 3, the column (5) is made into a square shape, the slide plate (13) is fastened on the column (5) by screws, and the tension bolt (1) connects the upper cross beam through the nut (2). (3) and the lower beam (6) are pre-tightened on the column (5), and the column (5) is fixed between the upper beam (3) and the lower beam (6); the movable beam (4) is sleeved on the column (5) on the surface of the slide plate (13), the movable crossbeam (4) is close to the upper and lower surfaces of the slide plate (13) to install wedge backing plates (10), which are fixed by the wedge backing plate fixing bolts (11); the movable crossbeam (4) is close to the slide plate (13) Bolts (7) are screwed into the upper and lower facades of the upper and lower facades, and the wedge-shaped guide plate (12) is inserted between the wedge backing plate (10) and the slide plate (13). 7), the adjusting gasket (9) is sleeved on the bolt (7), between the façade o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com