Automatic belt tightener with changeable rigidity

A tensioning device and variable stiffness technology, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of abnormal sound of belt system, belt span vibration, uncommon elastic stop technology, etc., to achieve a simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] A preferred embodiment of the present invention is described in detail as follows in conjunction with accompanying drawing:

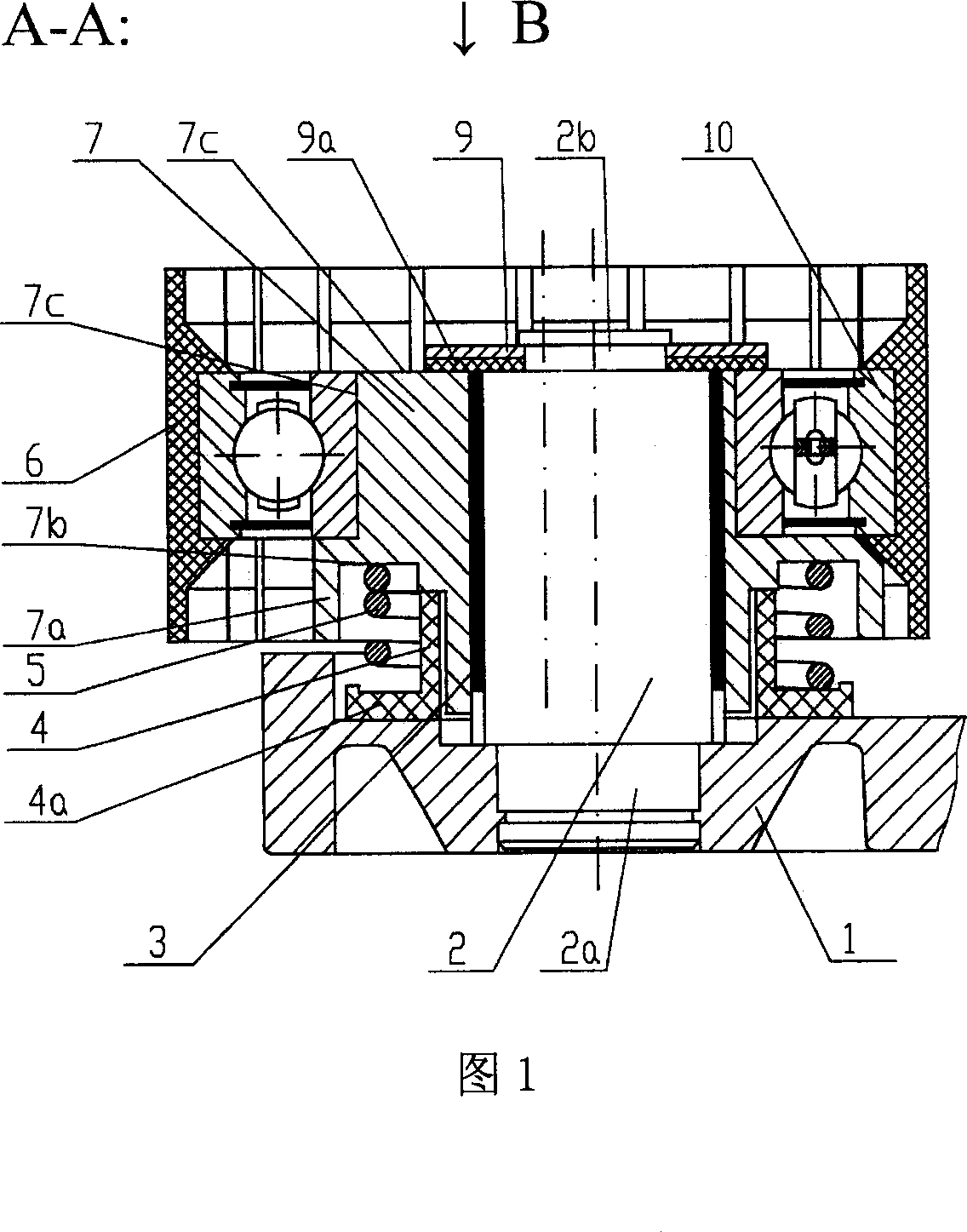

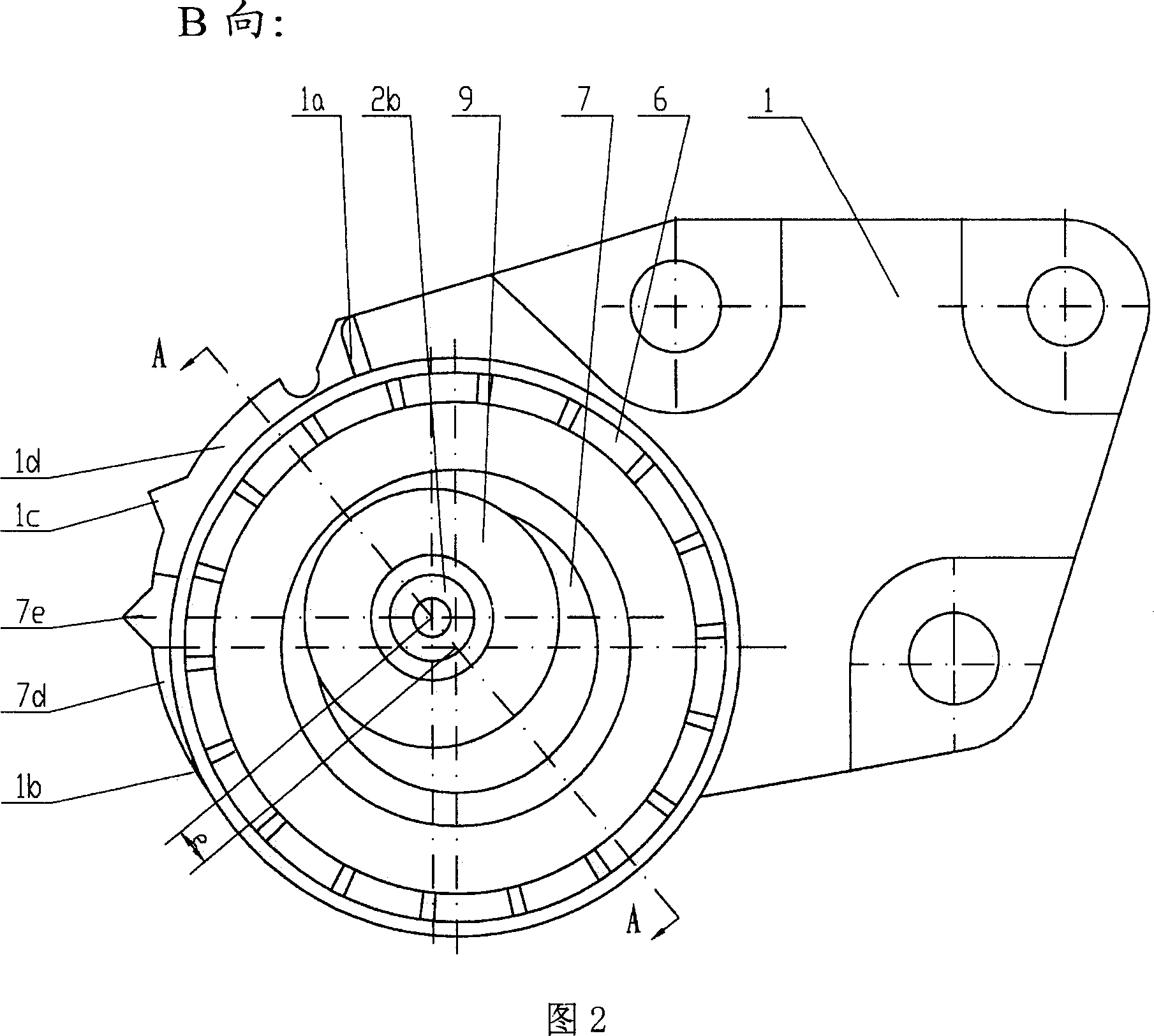

[0031] Referring to Fig. 1, this variable stiffness automatic belt tensioner includes a pulley 6, which is mounted on an eccentric wheel 7 through a rolling bearing 10. The inner ring of the bearing 10 is fixed on the outer circle 7c of the eccentric wheel. The eccentric wheel 7 is sleeved on a mandrel 2 through a shaft sleeve 3 . The shaft sleeve 3 and the eccentric wheel 7 adopt an interference fit, while the mandrel 2 adopts a clearance fit. The bushing 3 is made of friction material. The friction material can be made of nylon with good self-lubrication and wear resistance, and the shaft sleeve can also be made of plastic-bronze-steel multilayer composite material. The sleeve material is not limited to the above materials. One end 2a of the mandrel 2 is fixed on the bottom plate 1, and the other end 2b is equipped with a disc 9. The disc ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com