Shell structure of water meter

A shell structure and shell technology, used in liquid/fluid solid measurement, measuring devices, instruments, etc., can solve the problems of short service life, complex structure, poor corrosion resistance, etc., and achieve long service life and good structural strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

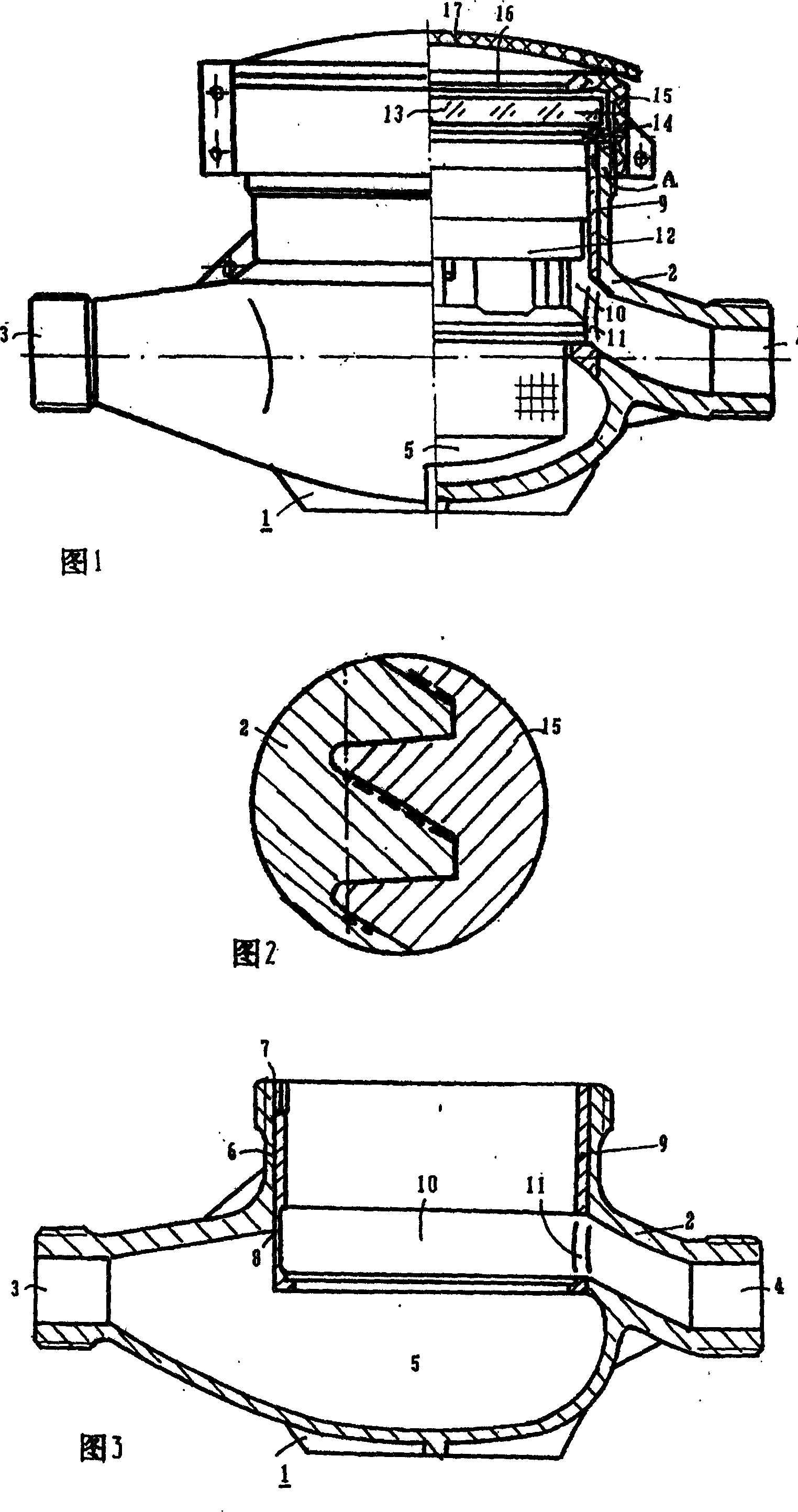

[0009] Please refer to the figure, a housing structure of a water meter. The housing 1 is composed of a housing and a water ring tank. The housing 2 has a fluid inlet 3 and an outlet 4 at both ends of the housing, a movement cavity 5 and a cylindrical water tank. Ring groove chamber 6, the upper mouth of water ring groove chamber is greater than lower mouth, and water ring groove body 9 is cylindrical, and its inner periphery has the water ring groove 10 that is the ring of opening, and the outer periphery of water ring groove body and water ring The inner circumference of the groove cavity 6 is in a sealed fit, and the water ring groove body 9 is embedded in the water ring groove cavity 6 of the shell 2, so that the opening 11 of the water ring groove communicates with the outlet 4 of the shell to form a shell 1. A water meter movement 12 is housed in the body, the lower part of the movement is placed in the movement cavity 5, the upper part of the movement cooperates with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com