Method for research carbocoal constriction performance in pyrogenation processing of coal

A technology of shrinkage characteristics and coal pyrolysis, applied in the fields of coal science and coal chemical industry, can solve the problems of unresolved shrinkage characteristics of semi-coke, and achieve the effect of improving production efficiency and product quality, and avoiding delayed coking discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach I

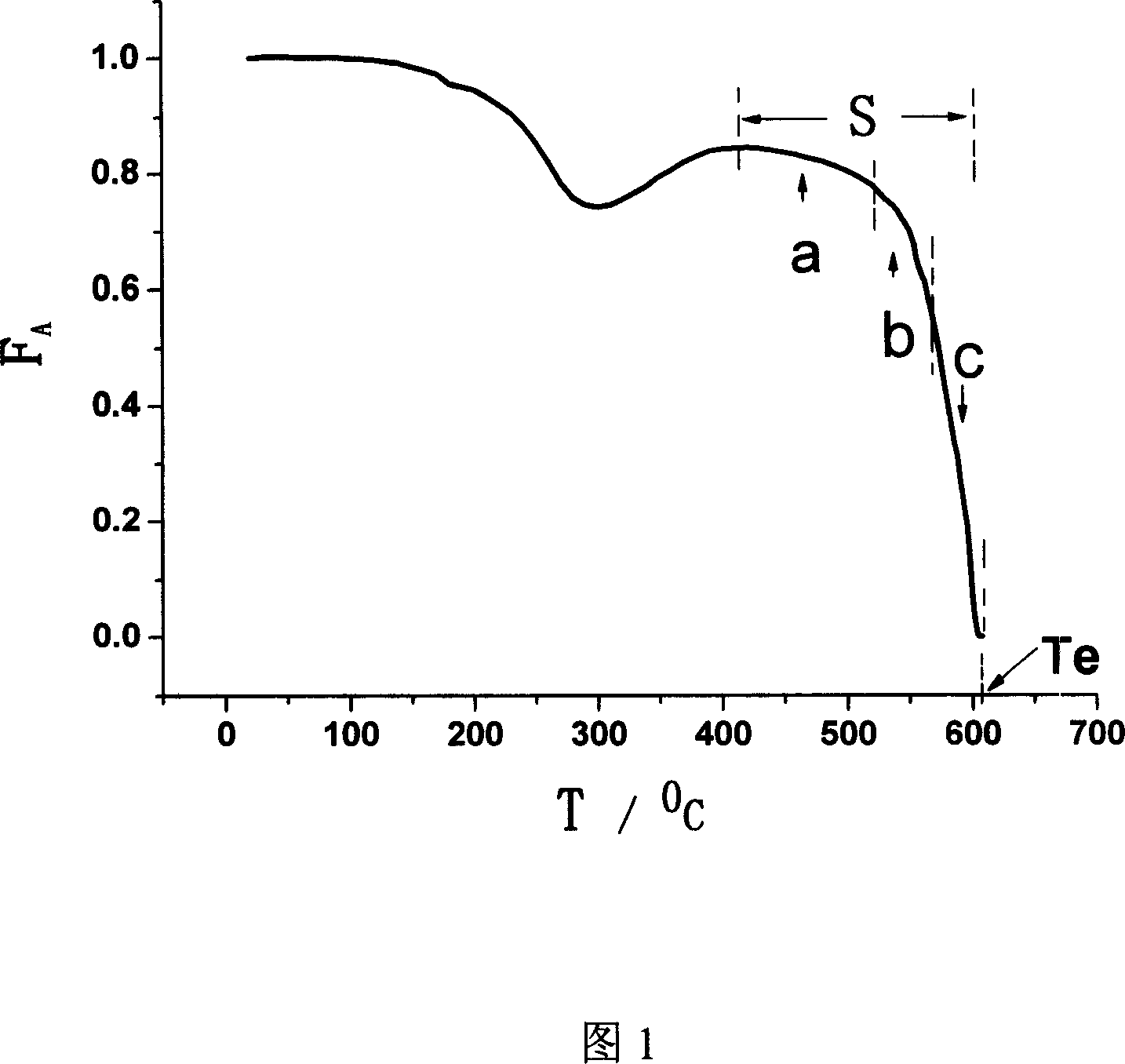

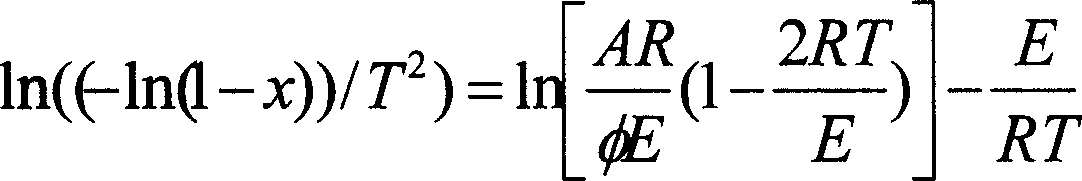

[0018] Sampling with a capillary tube to ensure that the research on each sample is comparable. Put the coal sample horizontally in the sample pool, and each sample has the same thickness. Adjust the light intensity of the microscope to 10, turn the hot stage into N 2 (The flow rate is 120mL / min), turn on the circulating cooling water, start the temperature rise and temperature control program, and heat from room temperature to the final temperature when the temperature rise rate is 5K / min; use the image analysis software configured by the microscope system, select the exposure time 51.5ms, gain 2.1, white balance 49, 2.90, 16 to make the image quality the best, every certain temperature is synchronously collected microscopic pictures by digital camera and saved for image analysis. The thermal decomposition of coal particles shrinks both horizontally and vertically, which is manifested in the reduction of the area of coal particles on the micrograph. The micrographs collect...

specific Embodiment approach II

[0029] Place the platinum crucible containing Shendong raw coal particles in a micro-heating stage, the temperature rise rate is 10K / min, and the others are the same as the specific embodiment I. The end temperature of the semi-coke shrinkage of this sample is 650°C, and the calculation results of the kinetic parameters of the three stages during the semi-coke shrinkage process are shown in Table 3:

[0030]Table 3 Kinetic parameters of Shendong raw coal semi-coke shrinkage process at 10K / min

[0031]

specific Embodiment approach III

[0033] Place the platinum crucible with the Pingshuo vitrinite particles on a micro-heating stage with a heating rate of 20K / min, and the others are the same as in Embodiment 1. The end temperature of the semi-coke shrinkage of this sample is 790°C, and the calculation results of the kinetic parameters of the three stages during the semi-coke shrinkage process are shown in Table 4:

[0034] Table 4 Kinetic parameters of the semi-focus contraction process of Pingshuo vitrinite at 20K / min

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com