Defect distinguish based on three-dimensional finite element NN and quantified appraisal method

A neural network and quantitative evaluation technology, applied in the field of non-destructive testing, can solve problems such as slow speed and large amount of calculation, and achieve the effects of fast speed, high calculation accuracy and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

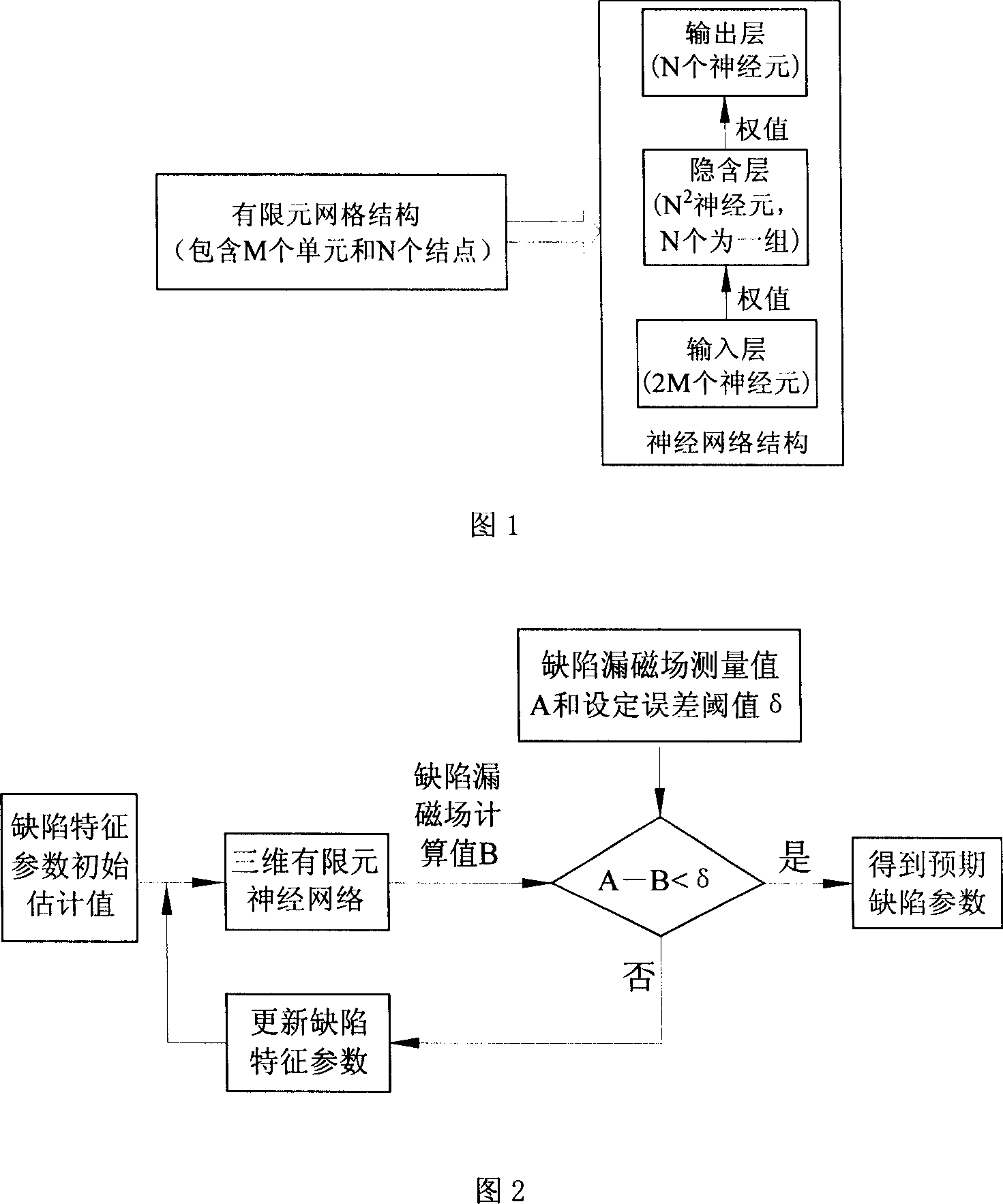

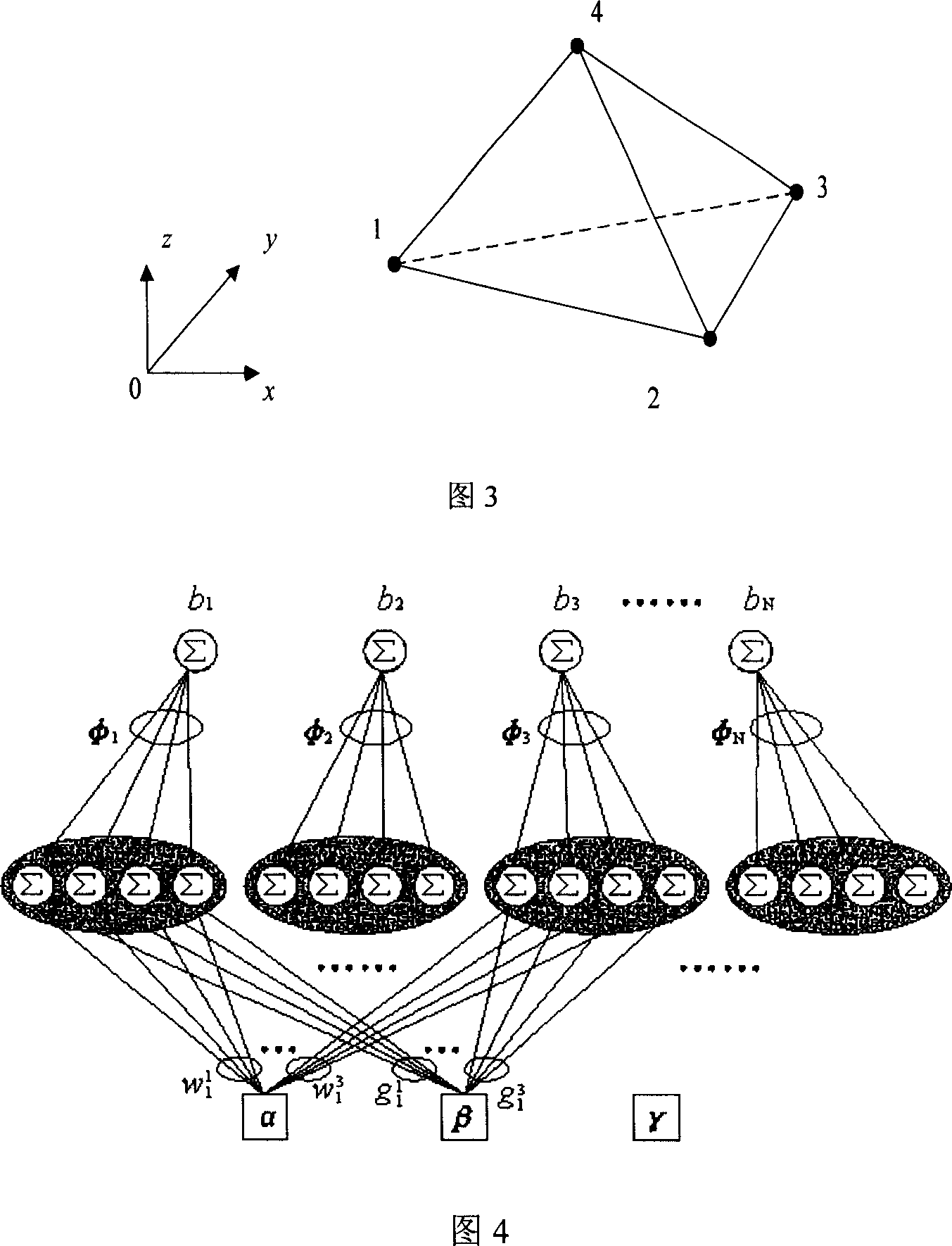

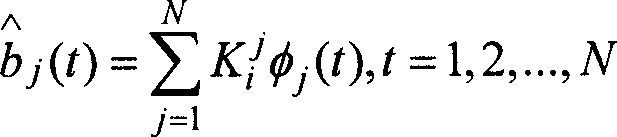

[0015] The defect identification and quantitative evaluation method based on the 3D finite element neural network mainly includes the following three basic steps: 1) Construct a 3D finite element neural network according to the 3D finite element calculation model of the defect leakage magnetic field; 2) Measure and extract the defect leakage magnetic field eigenvalue, set the threshold condition of the error between the measured value and the calculated value of the defect leakage magnetic field; 3) given the initial estimated value of the defect characteristic parameter, use the three-dimensional finite element neural network to perform iterative calculation, and compare the calculated value of the measured leakage magnetic field The error between the defect and the eigenvalue is used to realize the identification and quantitative evaluation of the geometric feature of the defect.

[0016] Below in conjunction with accompanying drawing, above-mentioned each step is described f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com