A plasma display plate with cross structure of opening at the grid hole of aperture mask

A technology of plasma and mesh holes, which is applied in the direction of tube structure parts, solid cathode parts, gas discharge tubes/containers, etc., and can solve the problems of low luminous brightness and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

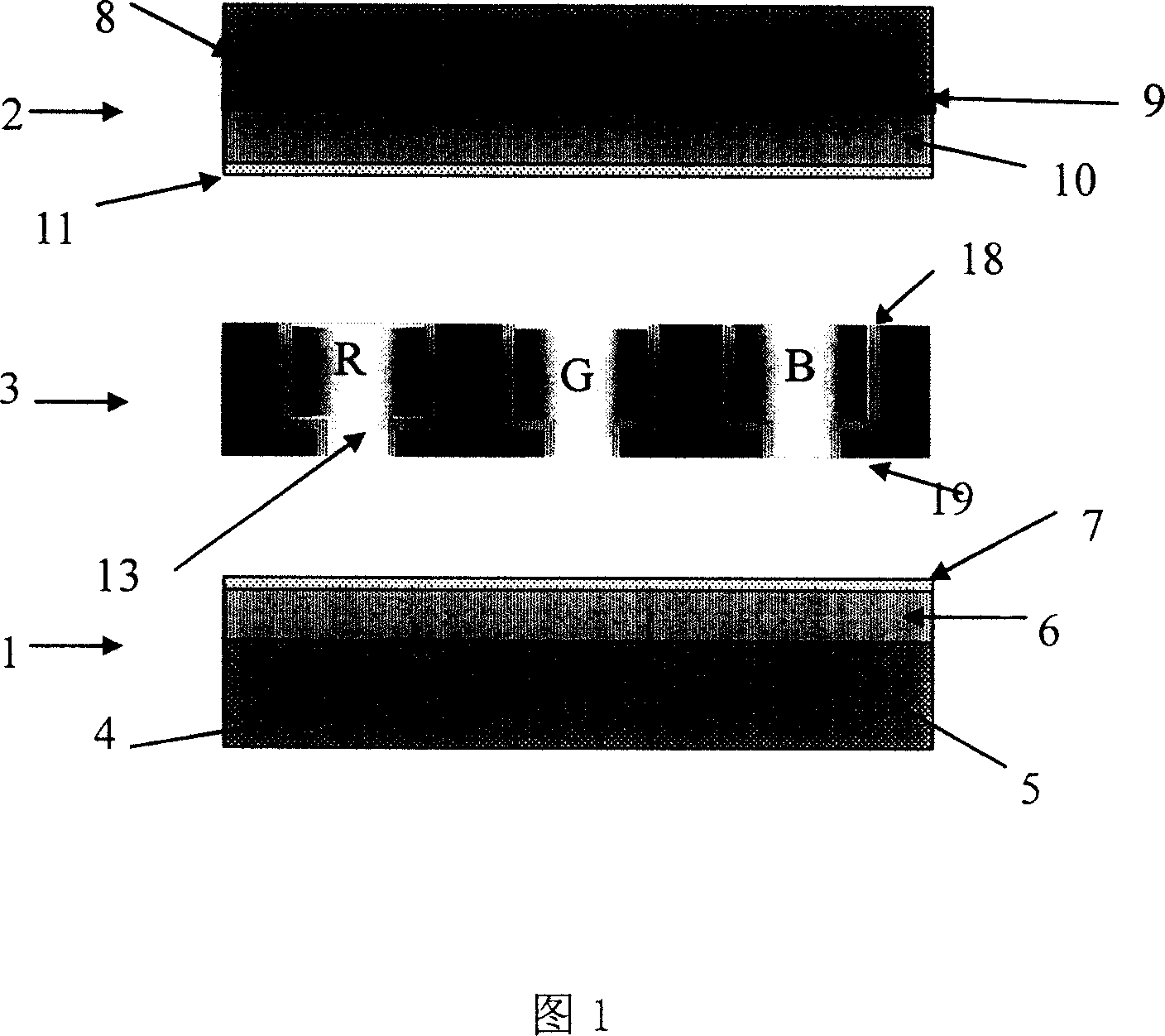

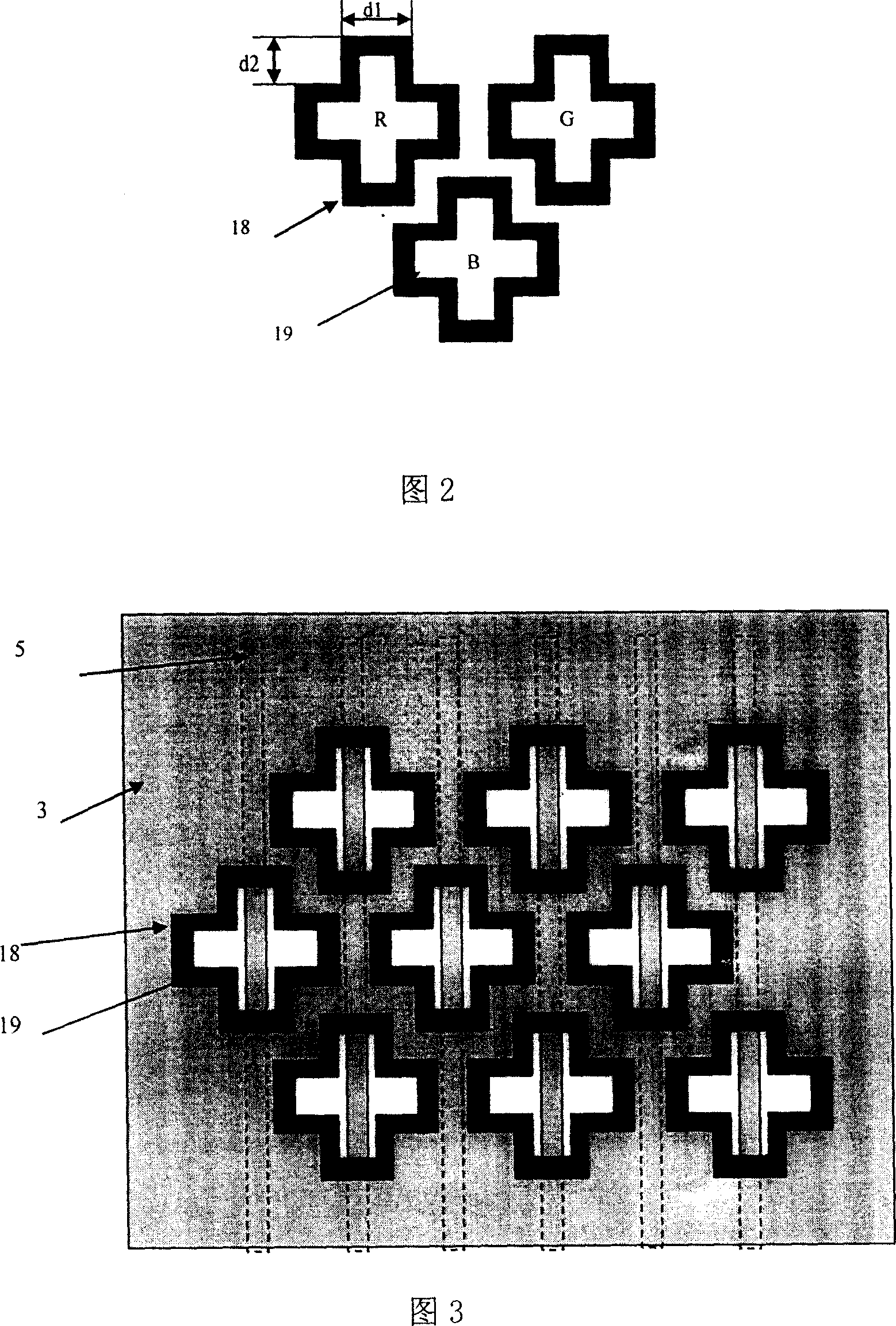

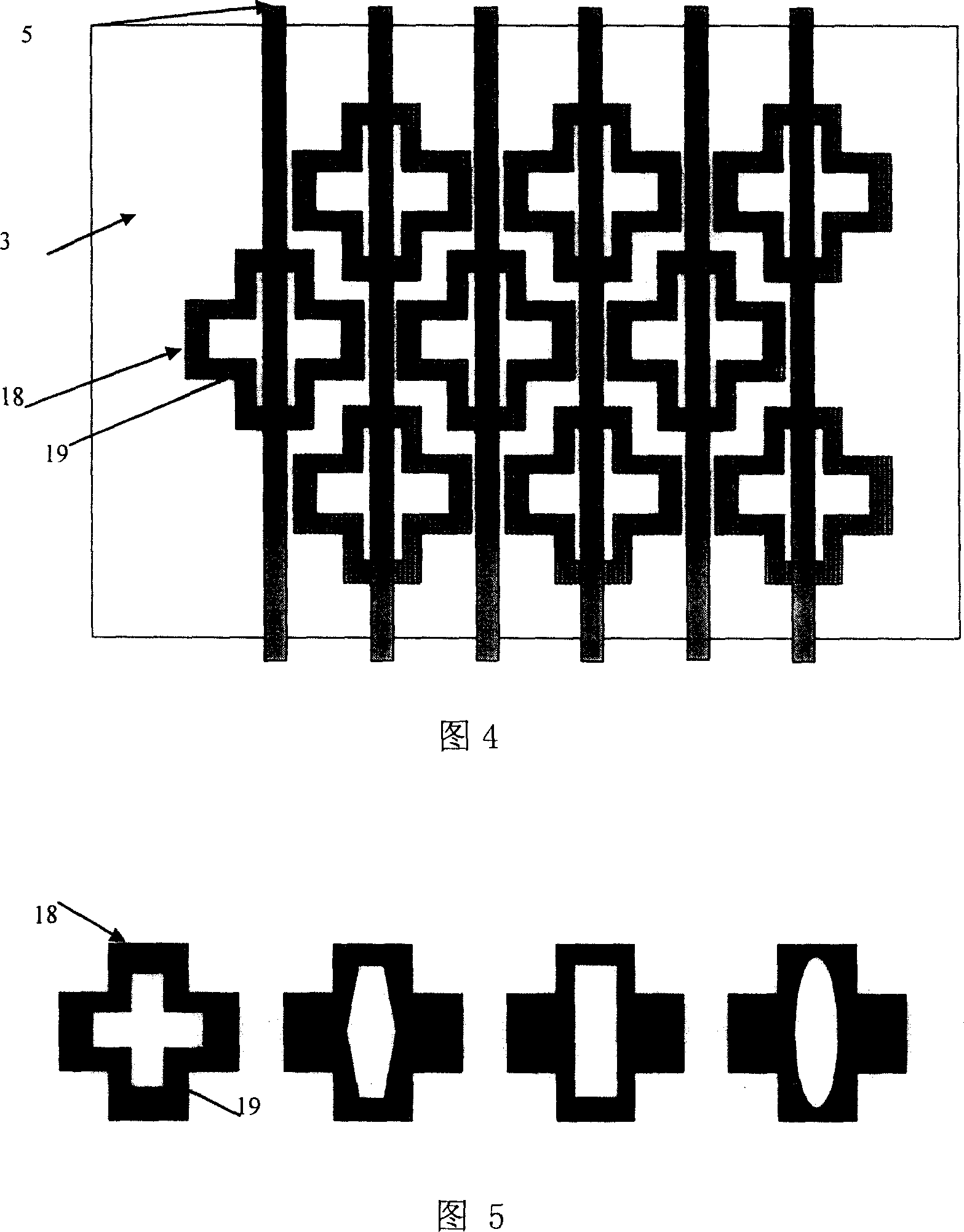

[0022] A plasma display panel with cross-shaped openings on grid holes of a shadow mask mainly consists of a rear substrate 1 , a shadow mask 3 and a front substrate 2 . The rear substrate 1 comprises a rear substrate glass substrate 4, the first electrode group 5 formed on the rear substrate glass substrate 4 is usually called a column electrode group or an address electrode group, and the rear substrate covering the first electrode group 5 The dielectric layer 6 formed on the glass substrate 4, the protective film 7 formed on the dielectric layer 6 surface; An electrode group 5 forms a second electrode group 9 vertically perpendicular to the space, commonly referred to as a row electrode group or a scanning electrode group, and a dielectric layer 10 formed on the surface of the front substrate glass substrate 8 covering the second electrode group 9, The protective film 11 formed on the dielectric layer 10; the shadow mask 3 sandwiched between the front and rear substrates 1,...

Embodiment 2

[0024] A plasma display panel with cross-shaped openings on grid holes of a shadow mask mainly consists of a rear substrate 1 , a shadow mask 3 and a front substrate 2 . The rear substrate 1 comprises a rear substrate glass substrate 4, the first electrode group 5 formed on the rear substrate glass substrate 4 is usually called a column electrode group or an address electrode group, and the rear substrate covering the first electrode group 5 The dielectric layer 6 formed on the glass substrate 4, the protective film 7 formed on the dielectric layer 6 surface; An electrode group 5 forms a second electrode group 9 vertically perpendicular to the space, commonly referred to as a row electrode group or a scanning electrode group, and a dielectric layer 10 formed on the surface of the front substrate glass substrate 8 covering the second electrode group 9, The protective film 11 formed on the dielectric layer 10; the shadow mask 3 sandwiched between the front and rear substrates 1,...

Embodiment 3

[0026]A plasma display panel with cross-shaped openings on grid holes of a shadow mask mainly consists of a rear substrate 1 , a shadow mask 3 and a front substrate 2 . The rear substrate 1 comprises a rear substrate glass substrate 4, the first electrode group 5 formed on the rear substrate glass substrate 4 is usually called a column electrode group or an address electrode group, and the rear substrate covering the first electrode group 5 The dielectric layer 6 formed on the glass substrate 4, the protective film 7 formed on the dielectric layer 6 surface; An electrode group 5 forms a second electrode group 9 vertically perpendicular to the space, commonly referred to as a row electrode group or a scanning electrode group, and a dielectric layer 10 formed on the surface of the front substrate glass substrate 8 covering the second electrode group 9, The protective film 11 formed on the dielectric layer 10; the shadow mask 3 sandwiched between the front and rear substrates 1, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com