Heat radiation method for transformer chamber

A technology of transformer room and heat dissipation method, which is applied in the field of power stations to achieve the effects of low ambient temperature, improving the environment and beautifying the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

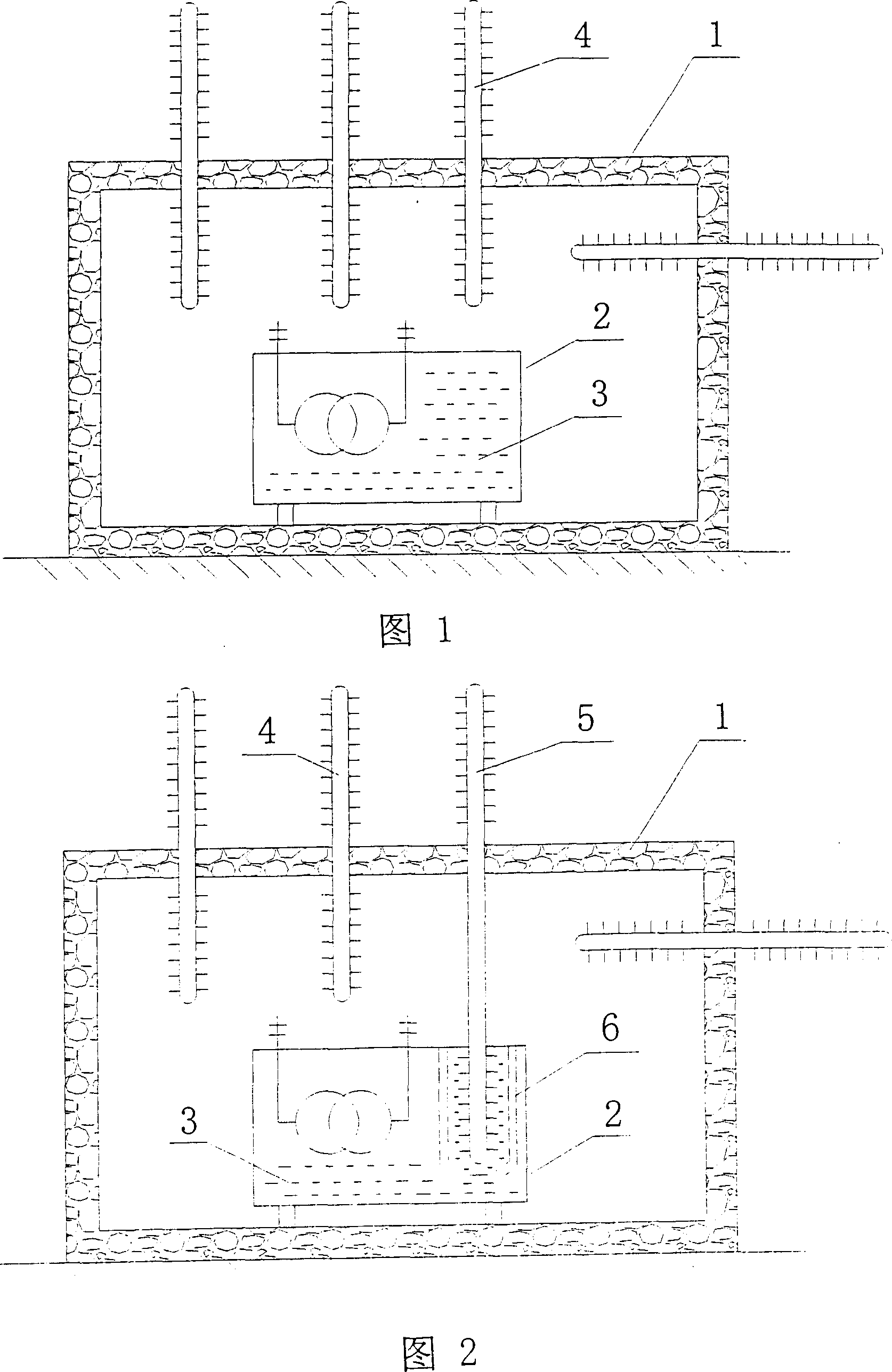

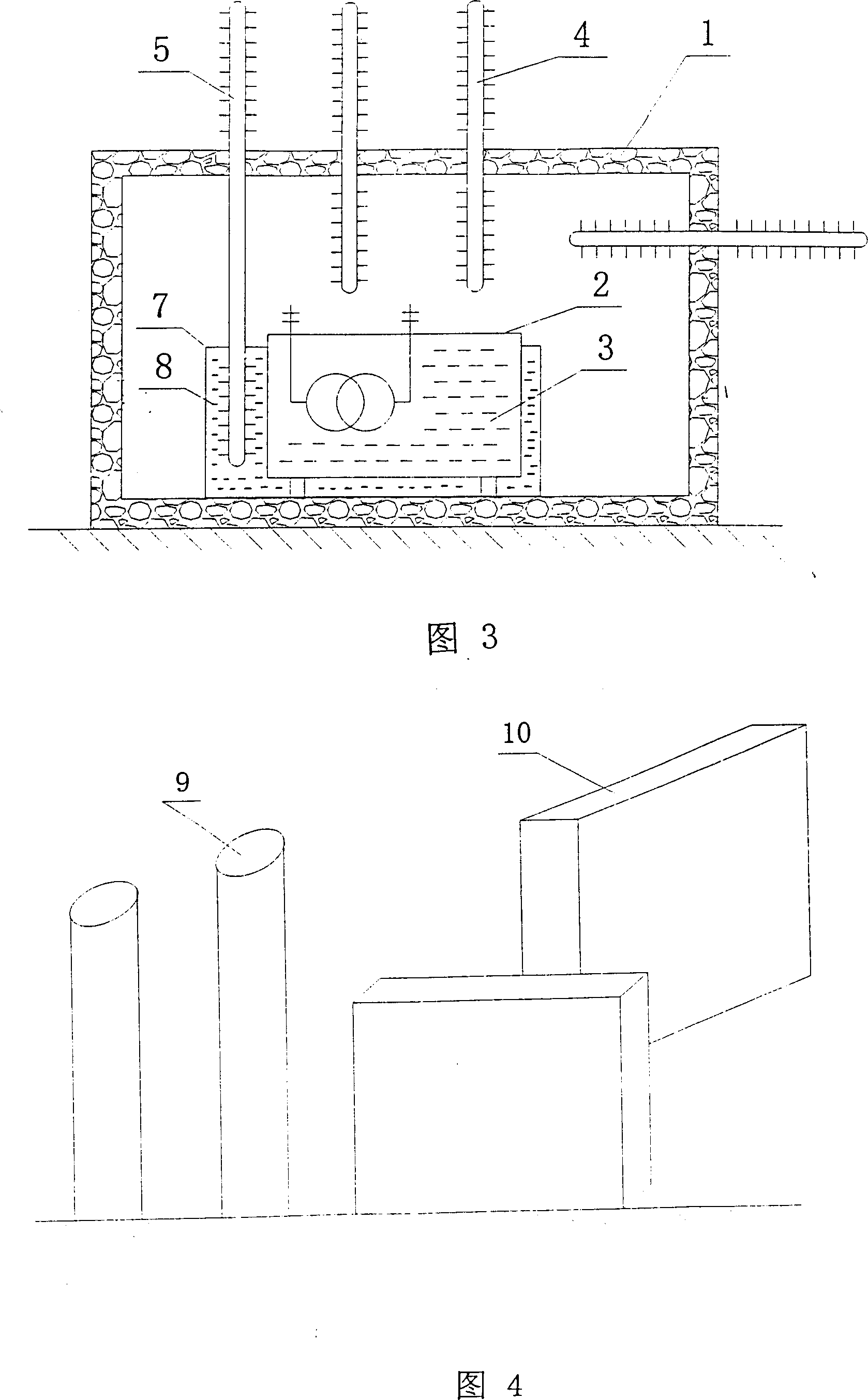

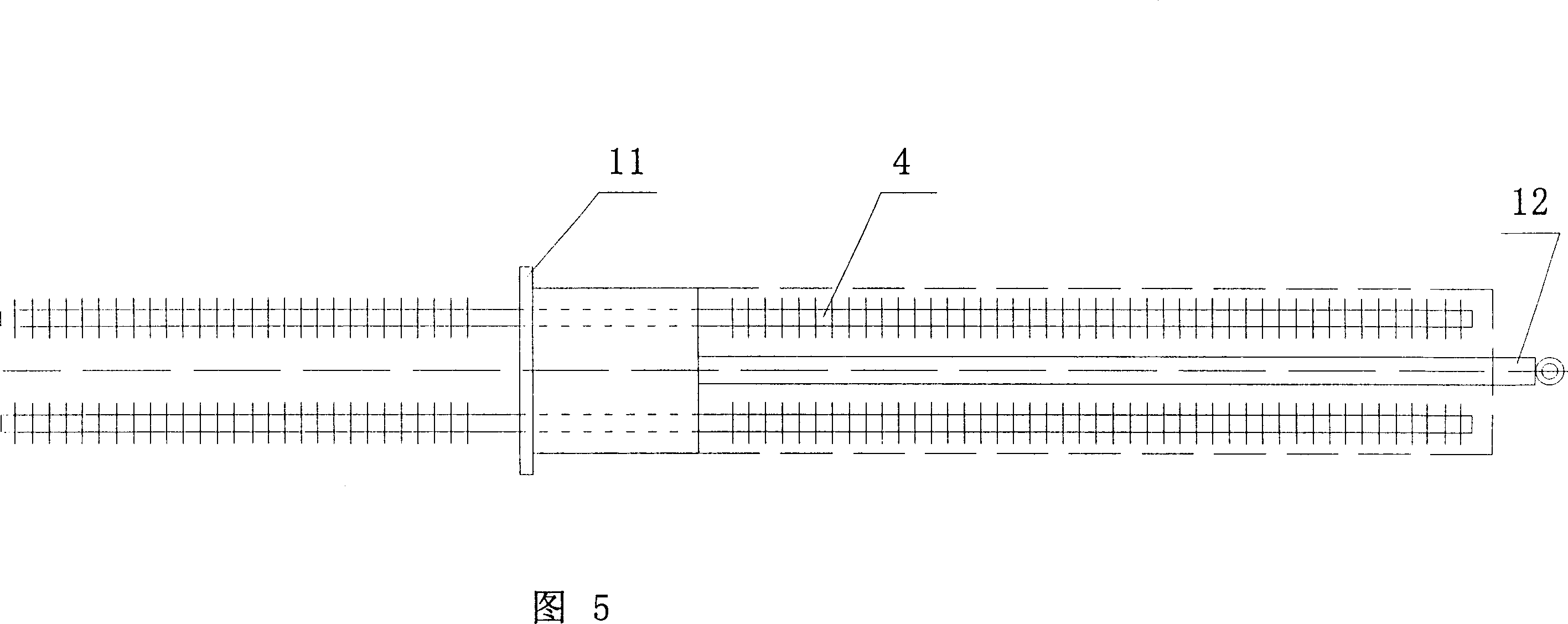

[0019] As shown in Figure 1, a heat dissipation method for a transformer room is characterized in that at least one set of heat pipes 4 composed of a heat absorption section, a heat dissipation section and a heat insulation section are inserted from the outdoors to the transformer room equipped with a transformer 2 or reactor In 1, the heat absorption section is placed indoors, the heat dissipation section is placed outdoors, and the adiabatic section is placed on the wall-through section. The heat absorption section absorbs the heat in the indoor air and transmits it to the heat dissipation section to be naturally emitted to the outdoor air. Each group of heat pipes can be composed of at least one heat pipe.

[0020] As shown in Figures 2 and 3, the heat absorption section of a group of heat pipes 5 is inserted into the oil 3 in the transformer tank or into the liquid 8 in the heat collecting tank 7 of the soaking transformer, and the heat is absorbed through the heat pipe and tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com