Press-in contact and method for the production thereof

A technology of contacts and pressing molds, which is used in the manufacture of contacts, fixed/insulated contact members, fixed connections, etc., can solve problems such as being susceptible to interference and insufficiency, and achieve the effect of large current carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

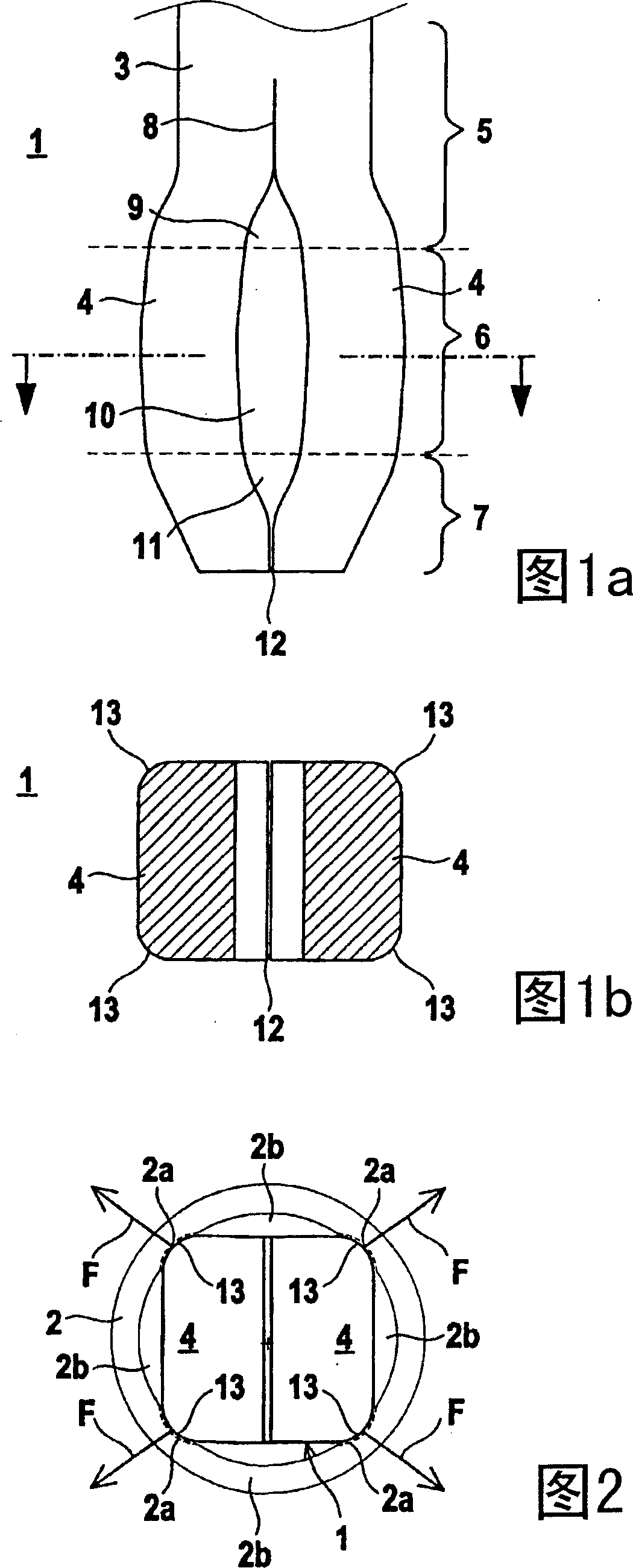

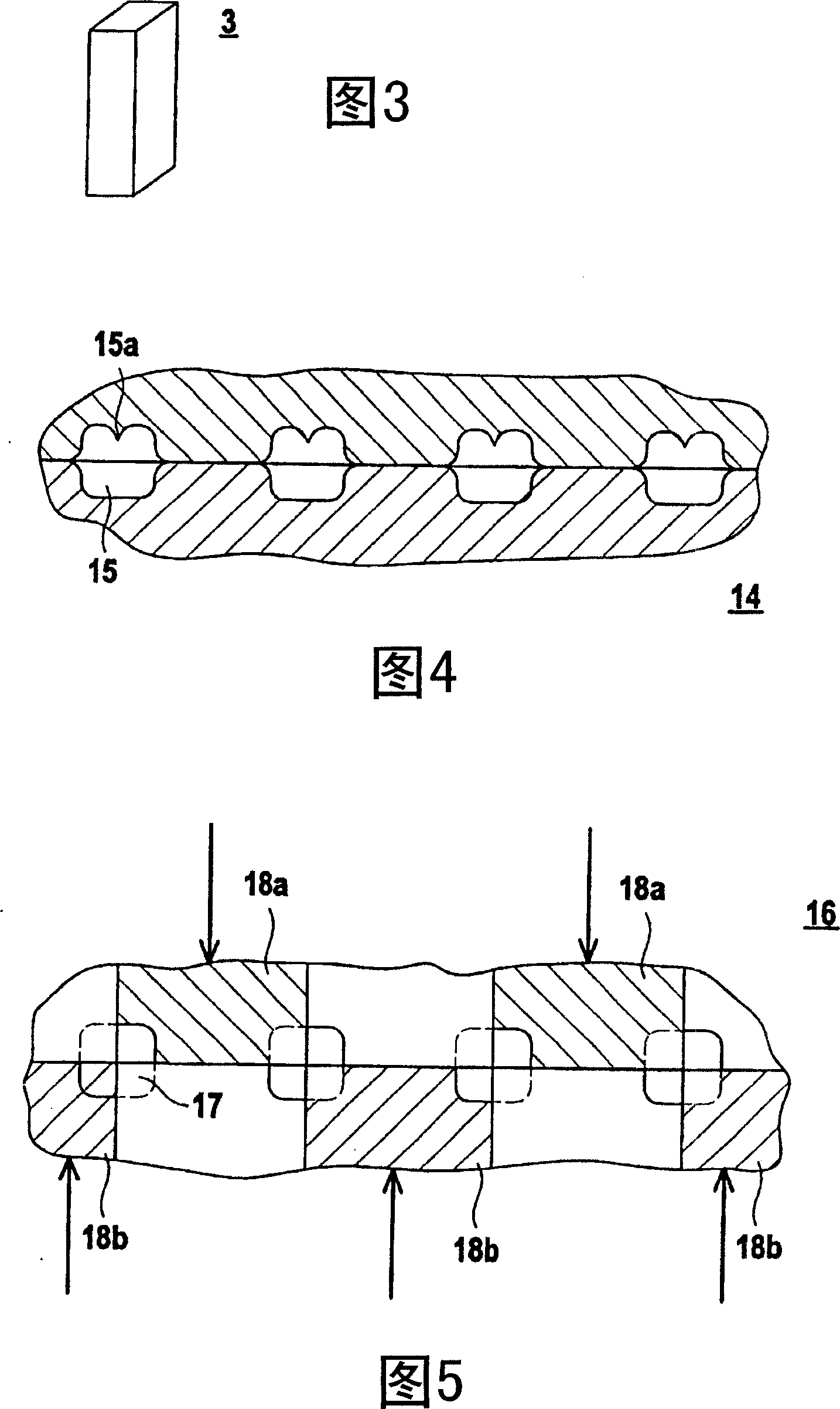

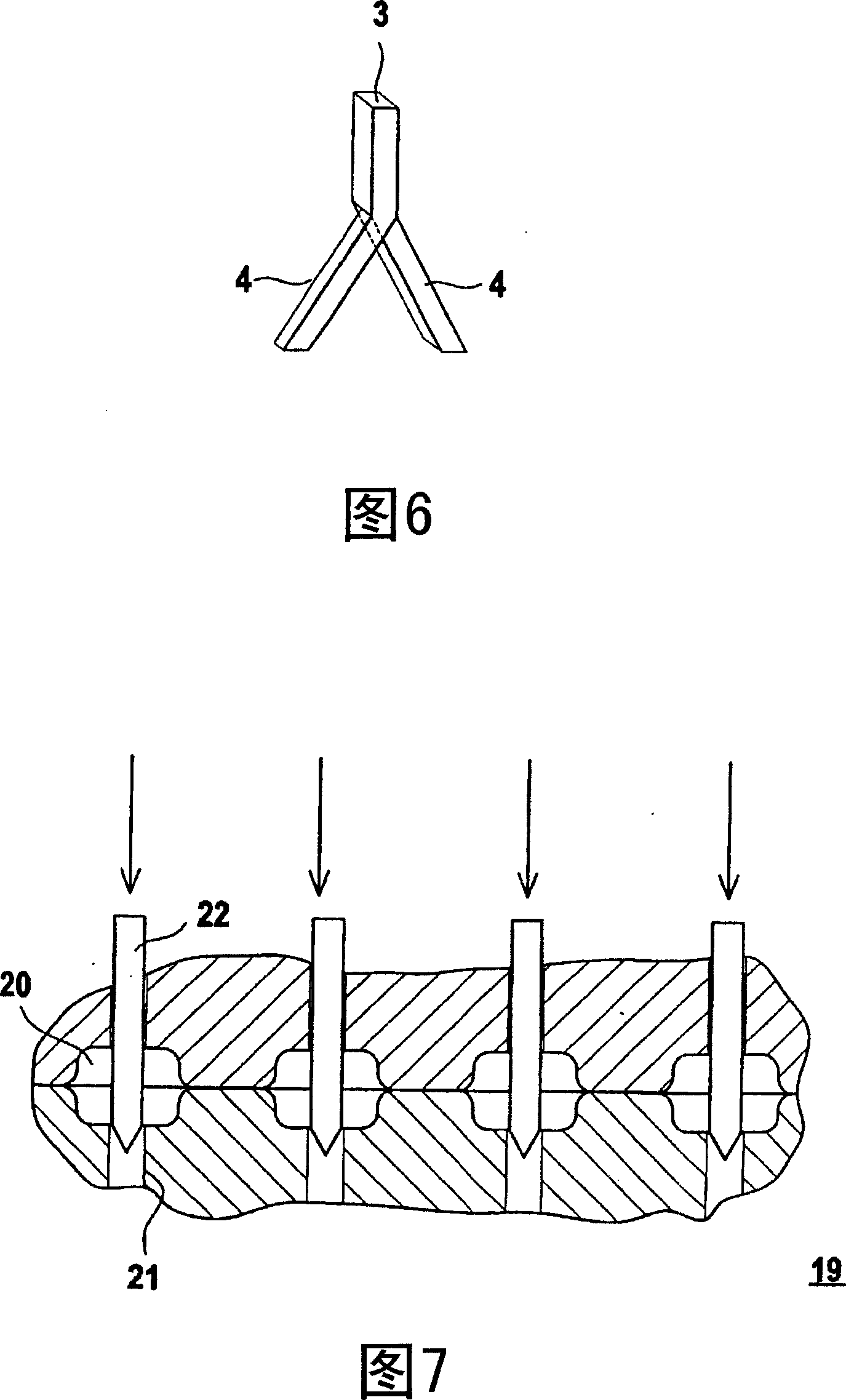

[0033] Figures 1a and 1b show an embodiment of a press-in contact 1. Fig. 1a shows a side view of the press-in contact 1 and Fig. 1b shows a cross section along the line A in Fig. 1a. As shown schematically in Fig. 2, the press-in contact can be press-fitted into a fully metalized hole 2 of a circuit board, wherein the hole 2 has a circular cross-section.

[0034] In the case shown, the press-in contact 1 is made of a brass piece. In this case, the press-in contact 1 has a contact body 3, and two side legs 4 freely merge on the underside of the contact body. The side legs 4 are formed by cutting or shearing to bring a separation extending along a separation surface into a section of the contact body 3, so that the side legs 4 are connected to the contact body 3. On the solid section that remains unchanged. Therefore, these side legs 4 are formed integrally with the contact body 3. The side legs 4 are formed uniformly and symmetrically to a plane of symmetry extending in the longit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com