Ultrasonic transducer and ultrasonic speaker using the same

一种超声换能器、固定电极的技术,应用在换能器电路、压电/电致伸缩换能器谐振换能器、压电/电致伸缩换能器等方向,能够解决不能保持振动膜振动的对称性质、频带窄、声音质量低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

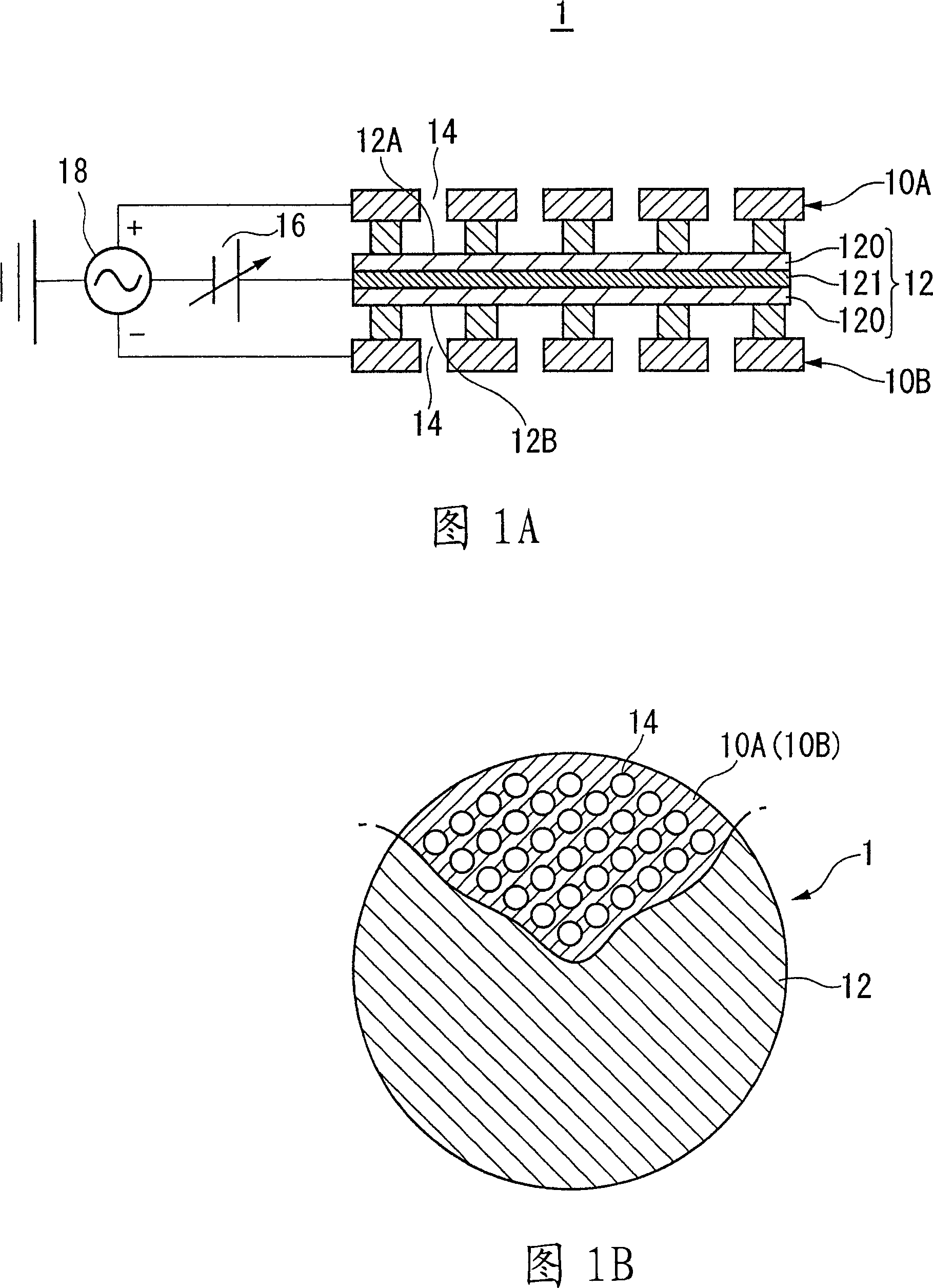

[0082] Embodiments of the present invention will be described in detail with reference to the accompanying drawings.

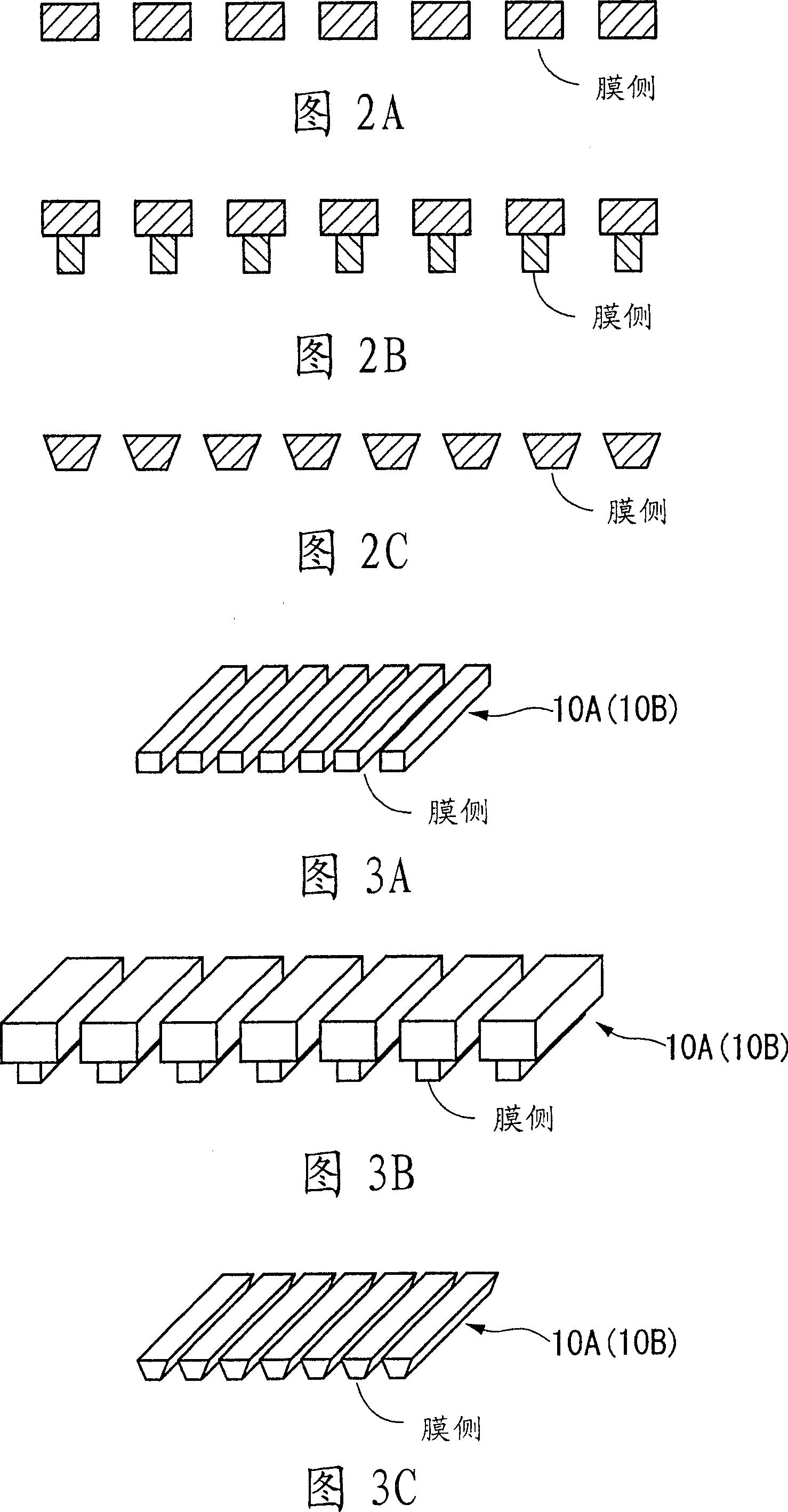

[0083] In FIGS. 1A and 1B , an ultrasonic transducer 1 according to the present embodiment includes: a pair of fixed electrodes 10A and 10B including a conductive member formed of a conductive material serving as electrodes; a vibrating membrane 12 having a conductive layer 121 and sandwiched between the pair of fixed electrodes; and a member holding the pair of fixed electrodes 10A and 10B and the vibrating membrane 12 (not shown in FIG. 1A or 1B, but having substantially the same the same structure as the housing 130). Hereinafter, the pair of fixed electrodes 10A and 10B may be referred to as a first fixed electrode 10A and a second fixed electrode 10B, respectively.

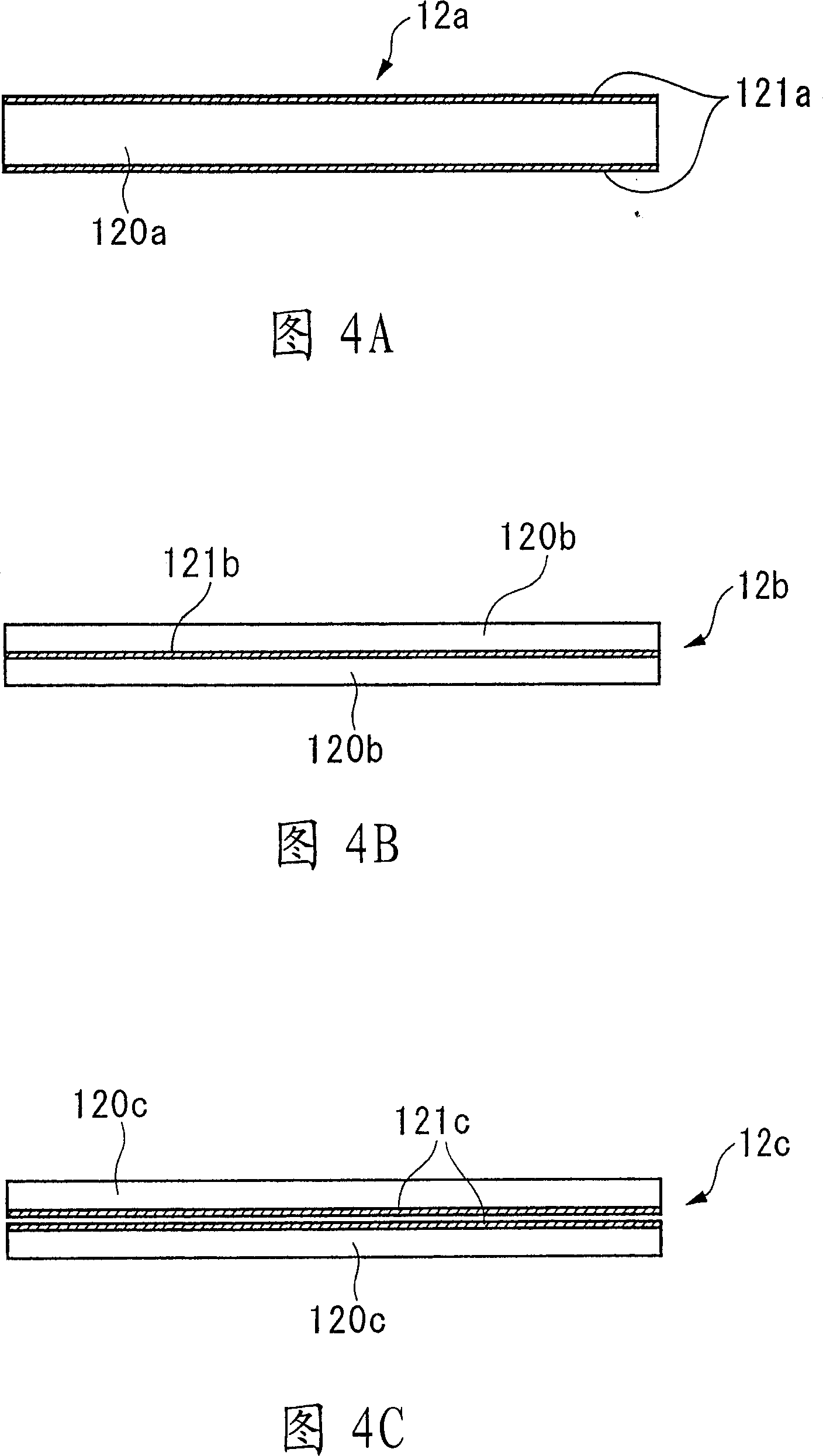

[0084] The vibrating membrane 12 is formed with a non-conductive body 120 and has an electrode layer 121 formed of a conductive material. A DC bias voltage having a single polarity (which m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com