Wallpaper embosser

An embossing machine and wallpaper technology, which is applied in the field of embossing machines, can solve the problems of easy wear and adjustment of plate-aligning deviation, many transmission stages of wallpaper embossing machines, high noise, etc., and achieves high plate-setting speed and adjustable plate-adjustment amount. The effect of tuning and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

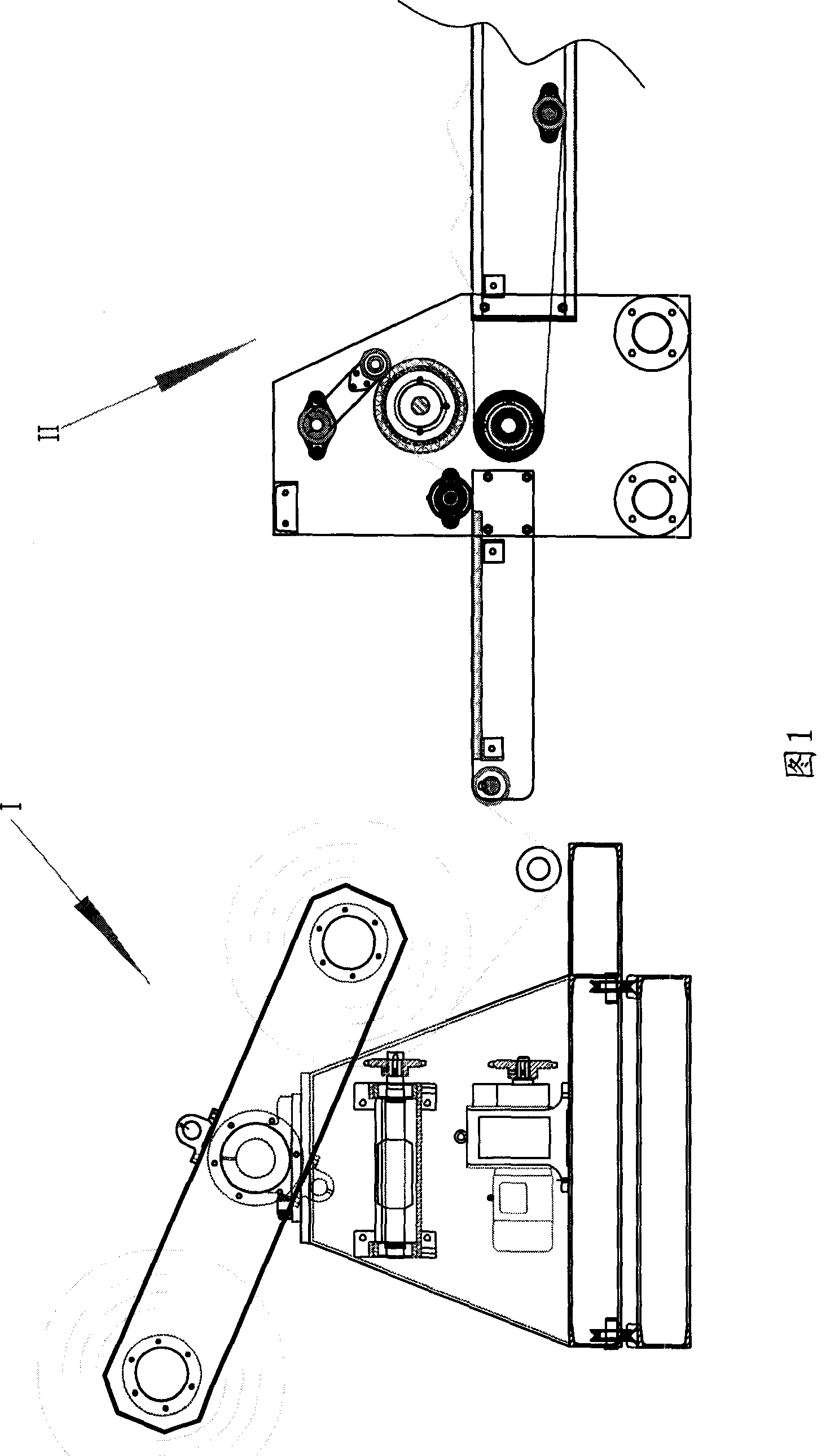

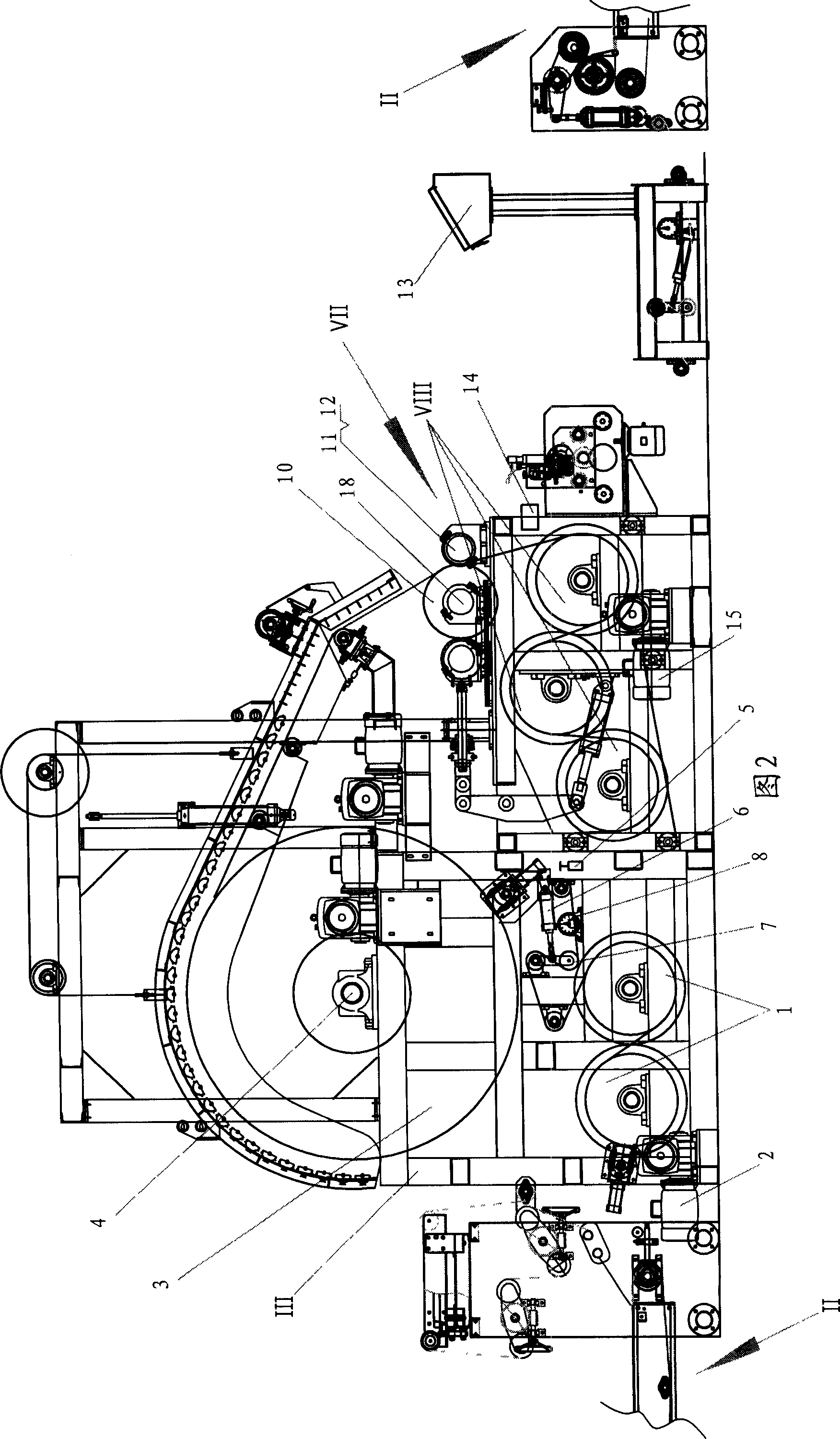

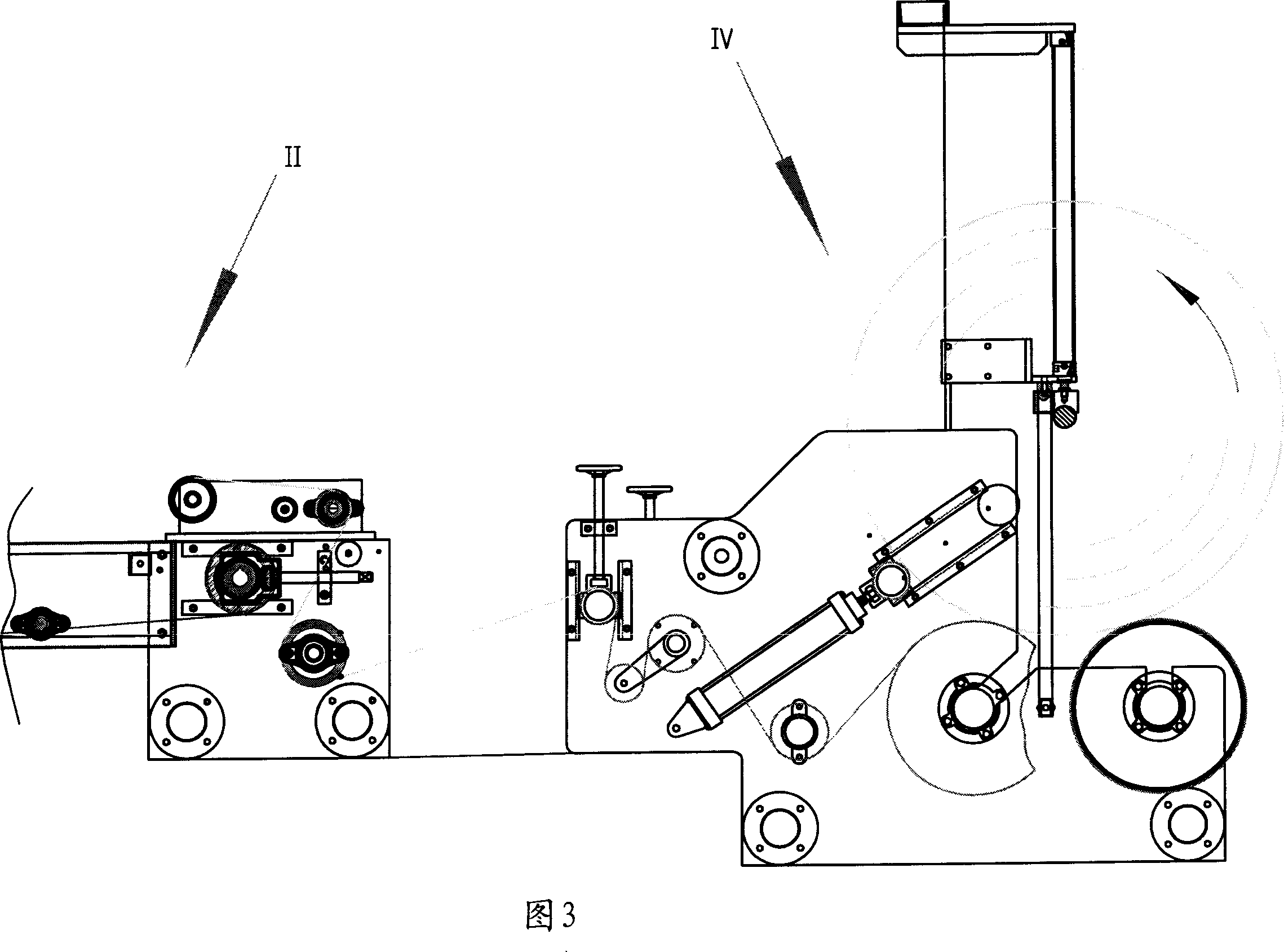

[0011] Referring to Figures 1 to 3, the wallpaper embossing machine includes a wallpaper unwinding device I, a conveying device II, a main frame III and a wallpaper winding device IV, and the opposite sides of the main frame III are respectively connected to the wallpaper unwinding device through the conveying device II I is connected with the wallpaper coiling device IV, and the main frame III is equipped with a heating device, a tension adjustment device, a cutting knife embossing device VII and a cooling wheel VIII, and the heating device, the cutting knife embossing device VII and the cooling wheel VIII are connected with each other. Independent drive servo motor transmission connection. Since the transmission between each part is independent, and through the action of strict position synchronization relationship, the alignment can be realized by adjusting the position deviation of the transmission of the cutter embossing device. The present invention removes the complex m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap