Instant-heating type electric heating boiler

An electric heating and rapid heating technology, applied in the field of heating boilers, can solve the problems of low thermal efficiency, low heat exchange rate, slow water flow rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

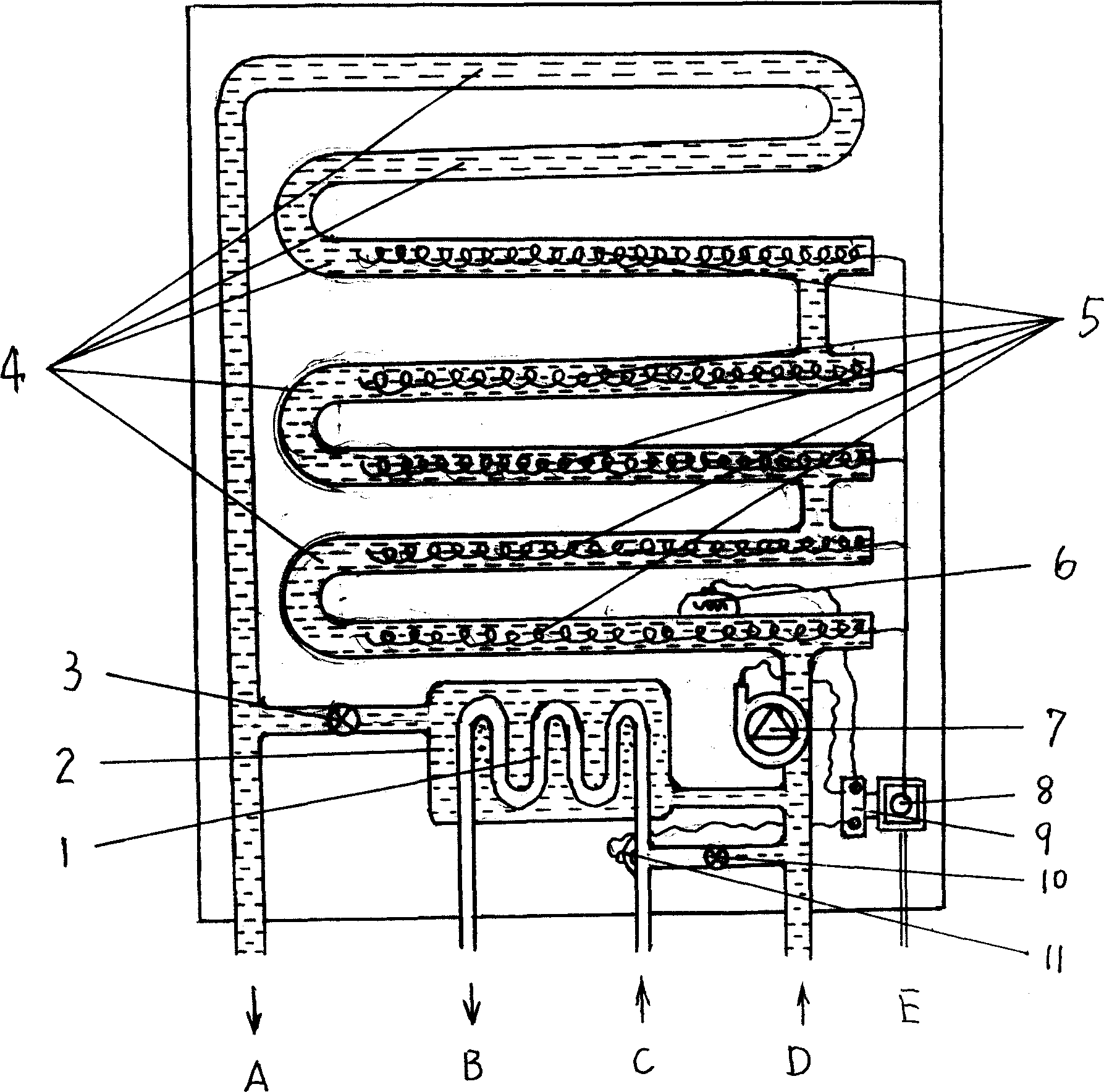

[0006] The details and working conditions of the specific device proposed according to the present invention will be described in detail below in conjunction with the accompanying drawings.

[0007] The rapid heating electric heating boiler is composed of a sanitary hot water pipe (1), a sanitary hot water heat exchanger (2), a split solenoid valve (3), a heating circulating water heat exchanger (4), an electric heater (5), Temperature sensor (6), circulating pump (7), electric heater automatic controller (8), computer program automatic controller (9), water supply switch (10), water flow sensor (11), heating circulating water outlet (A ), sanitary hot water outlet (B), tap water inlet (C), heating circulating water return port (D), power cord (E), etc. The heating circulating water heat exchanger (4) is made of multiple coiled metal tubes, and an electric heater (5) is placed inside each coiled metal tube, and the electric heater (5) and the electric heater are automatically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com