Exchange method of coking furnace basement gas heating system during overhauling of gas exchanger

A technology of gas heating and switching, applied in the heating of coke ovens, combustible gas heating coke ovens, coke ovens, etc., can solve the problems of increasing the chance of gas leakage and the impact of coke oven heating, so as to reduce the operation intensity without causing The effect of a gas leak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

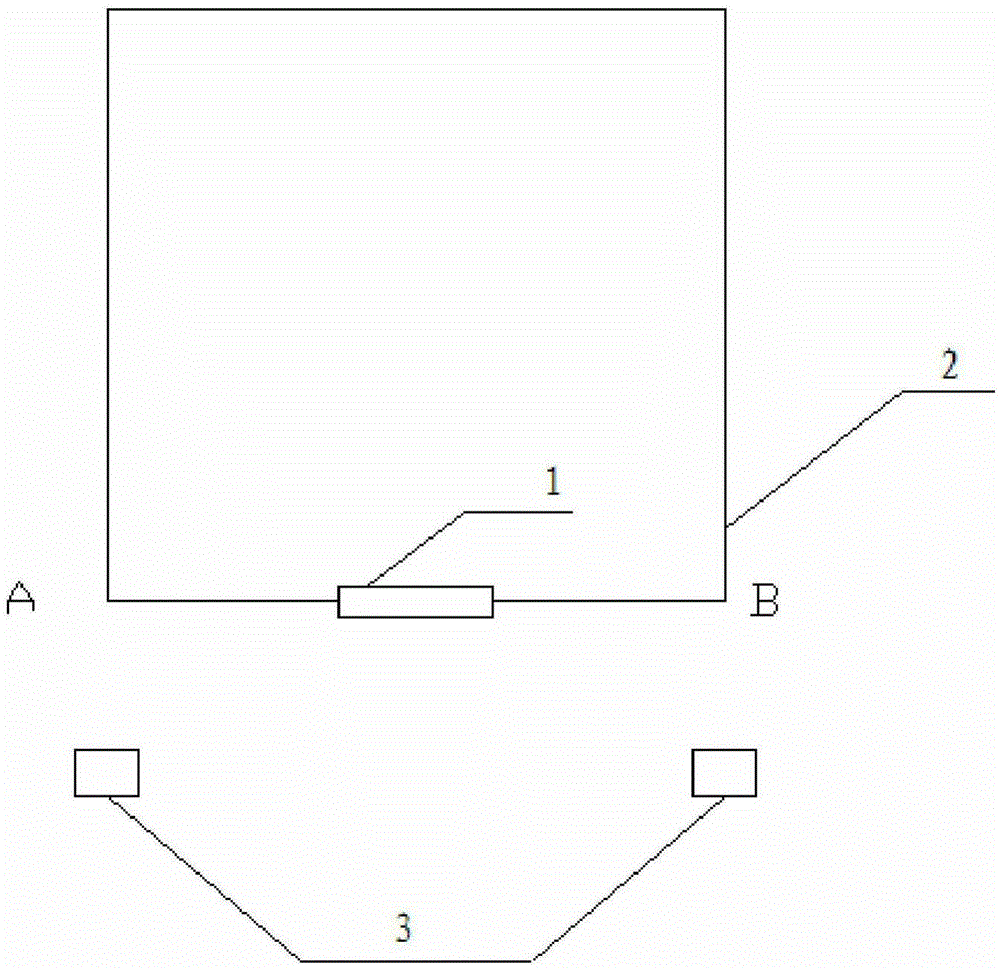

[0024] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

[0025] The method for exchanging the gas heating system in the coke oven basement during the maintenance of the gas exchanger of the present invention is applied to the exchange of the gas heating system in the basement of the waste gas circulation type coke oven when the exchanger is overhauled, and the exchange is performed by using an electric hydraulic cylinder, including the following steps:

[0026] Hang the hoist according to the method of chain hoist exchange and straighten the wire rope;

[0027] Remove the connecting part between the two ends of the exhaust gas hydraulic cylinder and the exhaust gas stroke;

[0028] Connect the exhaust gas hydraulic cylinder to the oil pipe of the electric hydraulic cylinder, and then conduct an empty test with electricity;

[0029] After the air test is normal, set the position of the hydraulic cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com