Biomass fuel environmental-friendly energy-saving furnace

A biomass fuel, environmental protection and energy saving technology, applied in the combustion of solid fuels, combustion equipment, fluid heaters, etc., can solve the problems of wasting heat energy, polluting the air and the environment, heat loss from boiler flue, etc., to save energy, burn Thorough, well-burning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

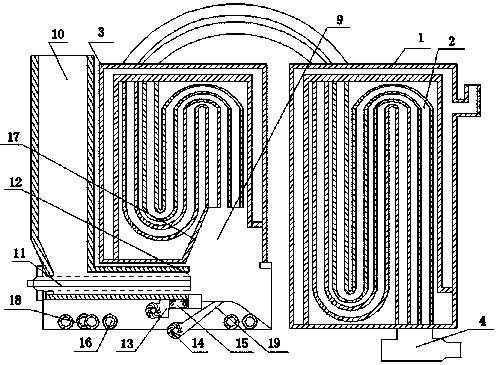

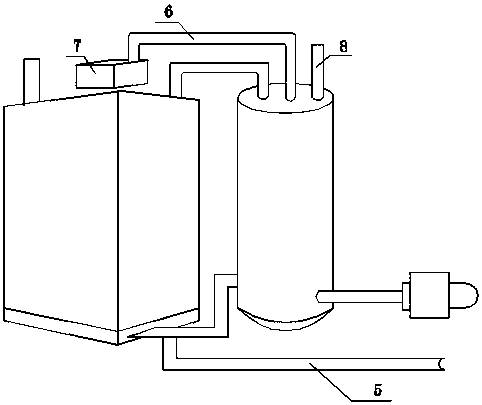

[0026] A biomass fuel environment-friendly and energy-saving furnace, as attached figure 1 , attached figure 2 As shown, its composition includes: a waste heat recovery accumulator body 1 with a circulating water pipe, a set of smoke introduction pipes 2 are installed in the waste heat recovery accumulator body, the smoke introduction pipes are connected to the boiler 3, and the smoke introduction pipes The other end is connected to the smoke machine 4. As for the biomass fuel environment-friendly and energy-saving furnace, there are 6 smoke introduction pipes. 6 smoke pipes are coiled and installed in the body of the waste heat recovery accumulator, so that the distance of waste heat flowing through the body of the waste heat recovery accumulator is long, and the effect of heat recovery is good. 6 smoke induction pipes make the combustion chamber form a multi-combustion chamber structure, ensuring that each smoke introduction pipe can work independently, even if one smoke ...

Embodiment 2

[0028] The difference between this embodiment and Embodiment 1 is that, as attached figure 1 , attached figure 2 As shown, in the biomass fuel environmental protection and energy-saving furnace, the waste heat recovery accumulator body is connected to the return water main line pipe 5, the other end of the return water main line pipe is connected to the furnace body, and the waste heat recovery energy storage The upper part of the accumulator body is connected to the overflow pipe 6, the overflow pipe is connected to the overflow water tank 7, and the upper part of the waste heat recovery accumulator body is connected to the hot water output pipe 8. When the hot water in the main line is used excessively, the hot water will flow out through the overflow pipe and be collected in the overflow water tank.

Embodiment 3

[0030] The difference between this embodiment and Embodiment 1 is that, as attached figure 1 , attached figure 2 As shown, the biomass fuel environmental protection and energy-saving furnace, the boiler includes a furnace body, the lower part of the furnace body has a combustion chamber 9, the smoke inlet of the smoke introduction pipe is located above the combustion chamber, and the combustion chamber A fuel tank 10 is connected, and a screw feeder 11 is installed at the bottom of the fuel tank.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com