Linear motor and method of producing linear motor

A linear motor and structure technology, applied in the manufacture of motor generators, stator/rotor bodies, electrical components, etc., can solve the problems of magnet manufacturing cost increase, increase in number of parts, cost increase, etc., achieve reliable assembly and reduce parts Number, effect of reliable assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] Hereinafter, although embodiment of the linear motor and the manufacturing method of the linear motor of this invention is demonstrated, this invention is not limited to this embodiment. In addition, although embodiment of this invention shows the most preferable embodiment of invention, this invention is not limited to this.

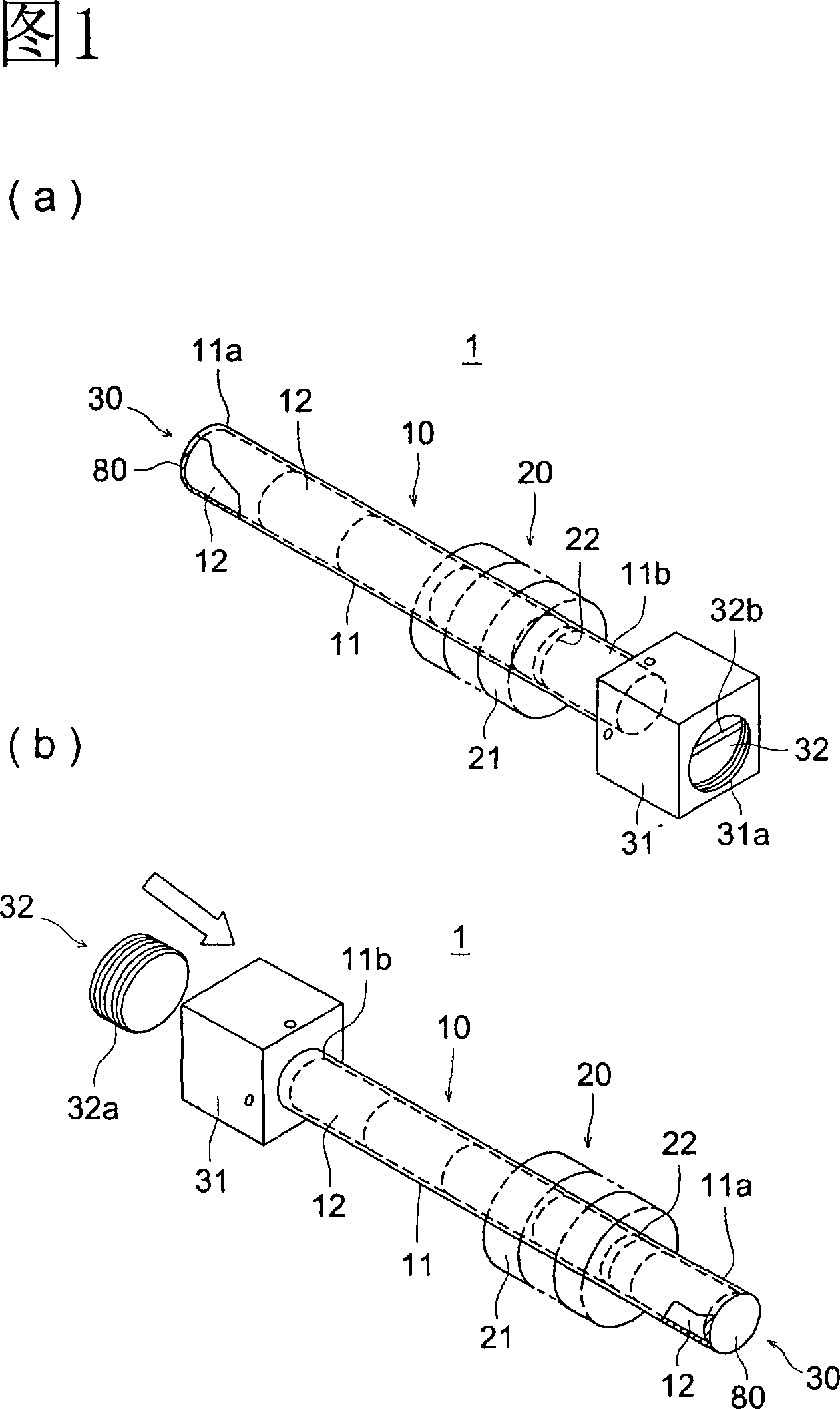

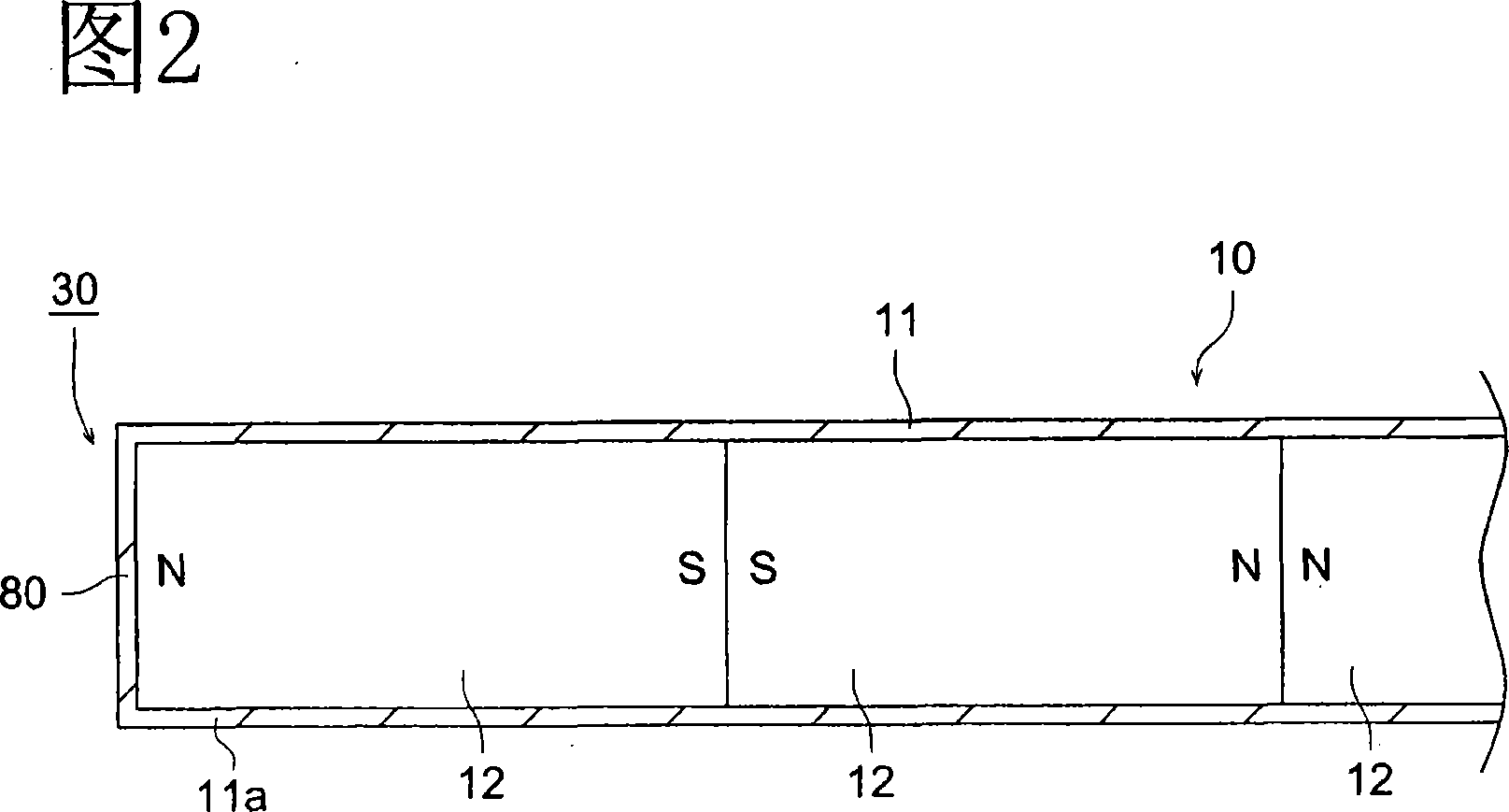

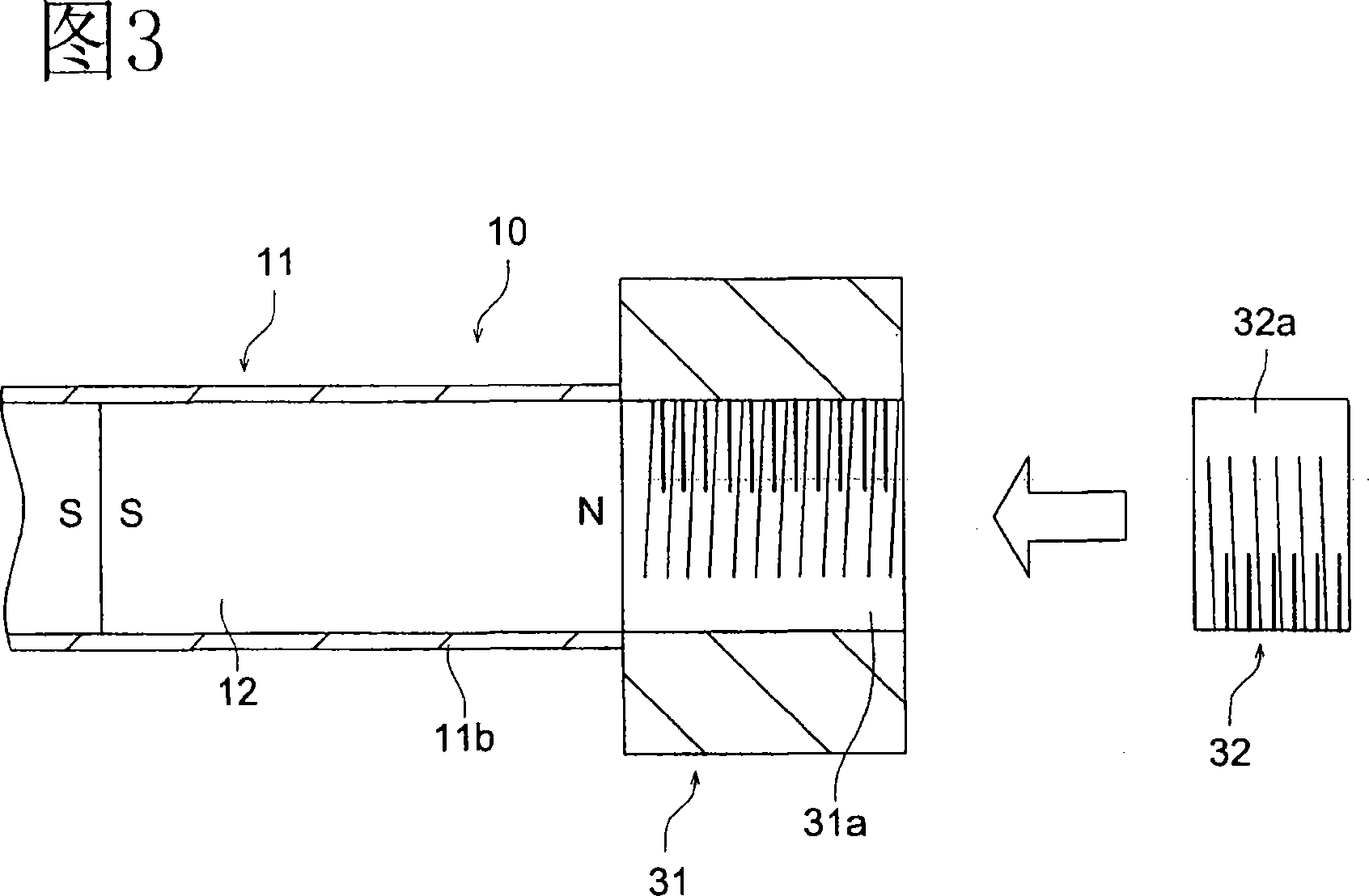

[0064] FIG. 1 is a schematic diagram of a linear motor, FIG. 2 is a sectional view of an essential part of one end of the linear motor, and FIG. 3 is a sectional view of an essential part of the other end of the linear motor.

[0065] The linear motor 1 of this embodiment is comprised of the stator 10 fixed to the support member which is not shown in figure, and the movable member 20 which linearly moves along the outer peripheral surface of the stator 10. As shown in FIG.

[0066] The stator 10 is composed of a duct-shaped member 11 and a plurality of magnets 12 accommodated in the duct-shaped member 11 . The plurality of magnets 12 arranged in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com