Special finned pipe shaped radiator for semiconductor refrigeration unit and its preparation method

A technology for refrigeration equipment and semiconductors, which is applied to semiconductor devices, semiconductor/solid-state device parts, heat exchanger shells, etc., and can solve the problems that parts are not easy to achieve standardized production, industrialized mass production cannot be realized, and welding quality is not guaranteed. , to increase the effective heat dissipation area, the production and processing technology is simple and reliable, and the yield is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings, but they are not intended to limit the present invention.

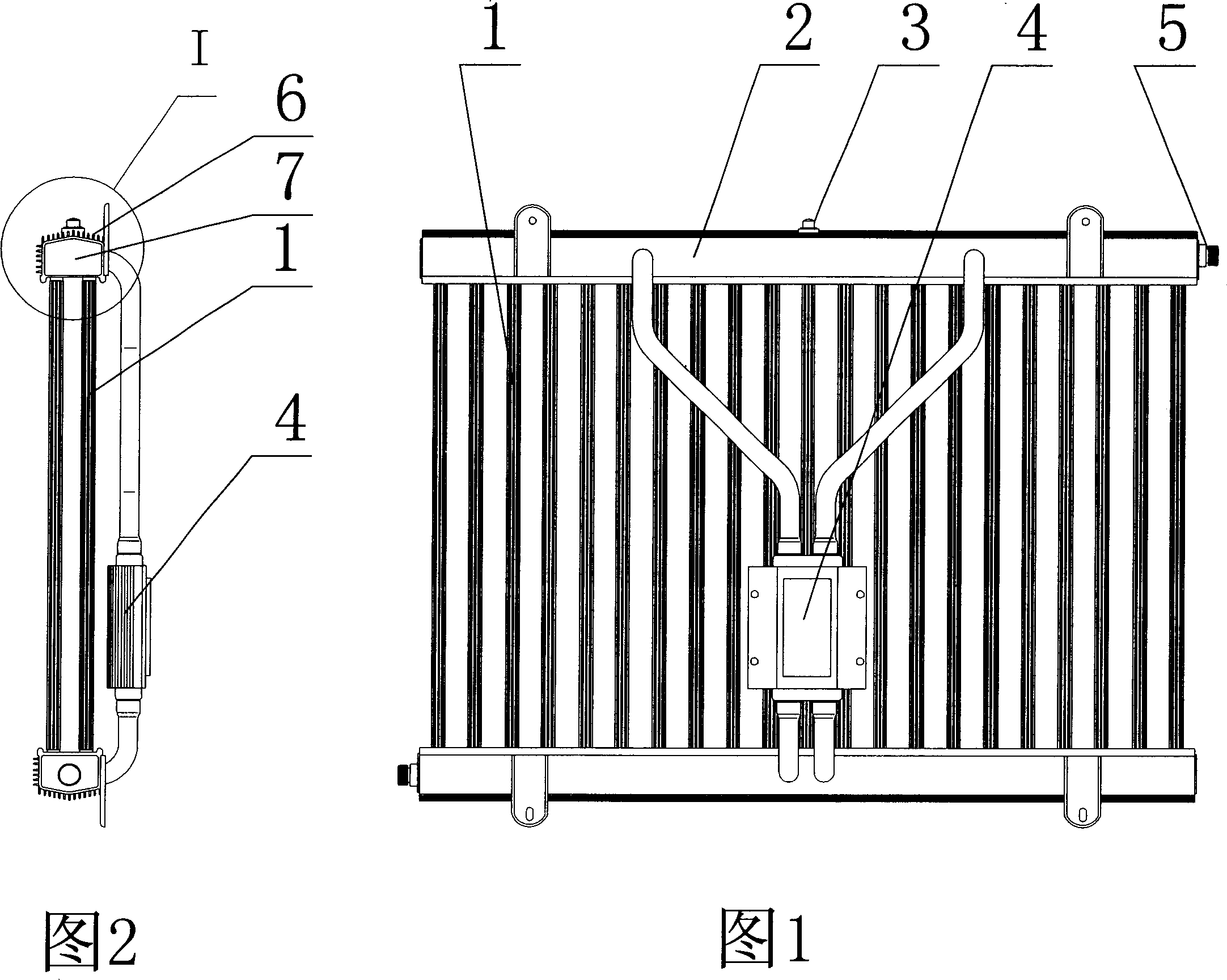

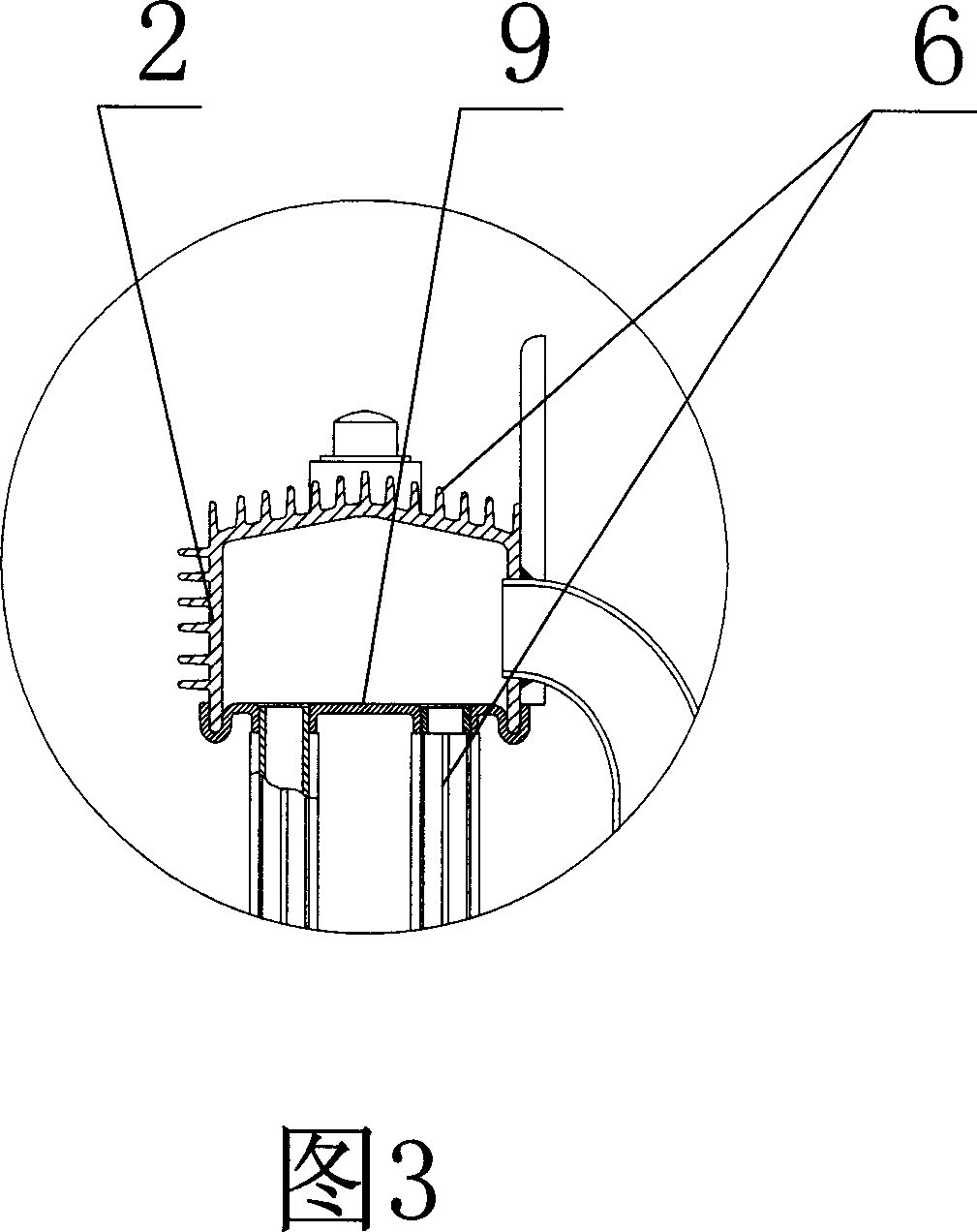

[0028] The finned tubular radiator for semiconductor refrigeration equipment includes a heat dissipation cavity formed by welding the standpipe 1 and the upper and lower horizontal tubes and communicating with each other, and an evaporator 4 that communicates with the cooling cavity through pipelines. The two ends of the horizontal tube are blind ends. Strip fins 6 are distributed on the outer surfaces of the horizontal tube and the standpipe 1 , and the strip fins 6 are radially and equiangularly distributed on the outer surfaces of the tube walls of the horizontal tube and the standpipe 1 and extend in the axial direction. The horizontal tube is a tubular structure composed of a bar-shaped end cap 2 with an arched section and a connecting plate 9 blocked at the strip-shaped opening of the bar-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com