Vehicle engine

An automobile engine and engine technology, which is applied to combustion engines, variable displacement engines, machines/engines, etc., can solve the problems of difficult adjustment of displacement, large size, loose overall structure of the engine, etc., and achieve overall size reduction, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

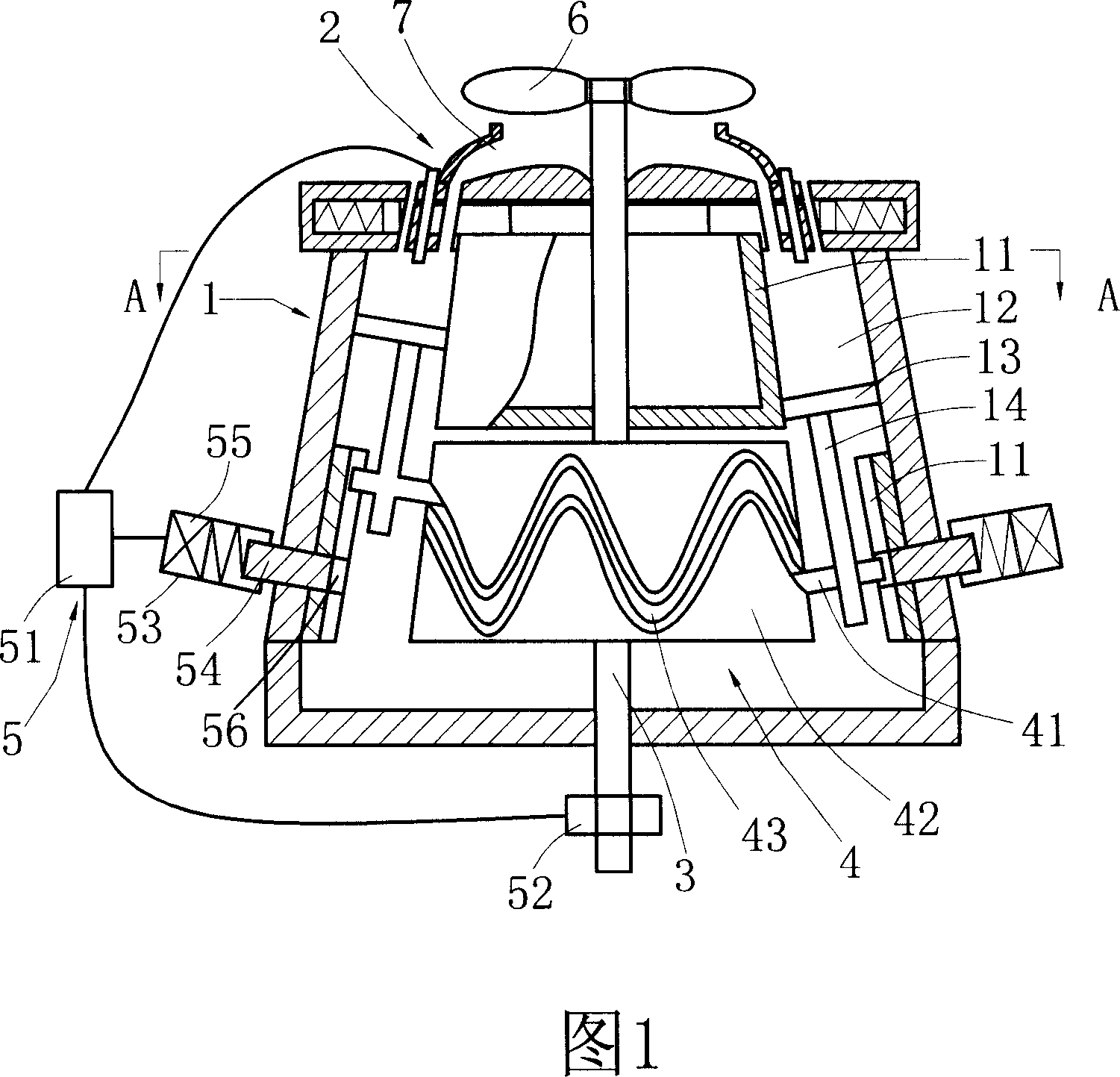

[0012] Embodiment 1: Refer to Fig. 1 and Fig. 2 .

[0013] This is an engine embodiment of the present invention that can adjust displacement and convert exhaust gas into power. The specific structure of the engine can be seen from Figure 1, which includes a cylinder block 1, a cylinder head 2, an output shaft 3, a transmission mechanism 4, and a control mechanism 5.

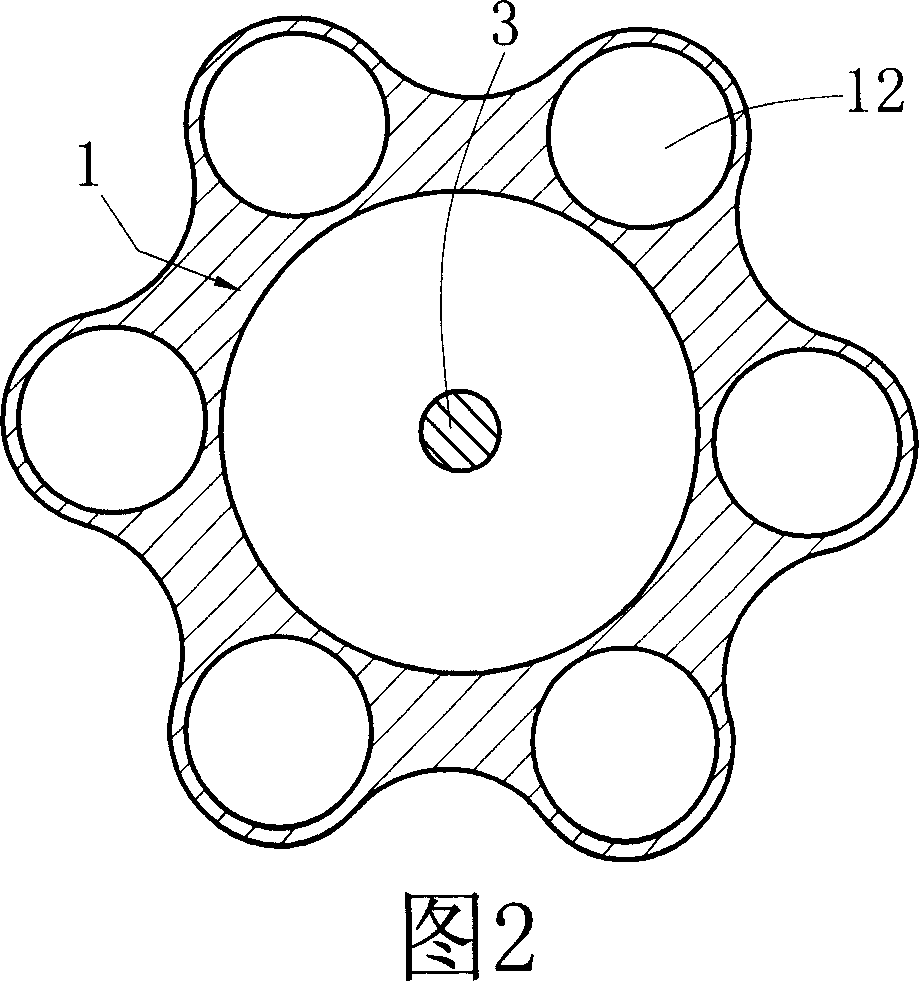

[0014] First let's look at cylinder block 1. Cylinder block 1 has a cylinder block 11, and at least one cylinder 12 is arranged around this cylinder block, and what Fig. 2 shows is six cylinders, and piston 13 and piston rod 14 are all arranged in each cylinder.

[0015] The transmission mechanism 4 is composed of a transmission rod 41 and a rotor 42. The rotor 42 is fastened on the output shaft 3. There is a wave-shaped transmission rail 43 on the rotor 42. The transmission rod 41 is installed on the piston rod 14. One end has a matching relationship with the transmission rail 43. , the other end is controlle...

Embodiment approach 2

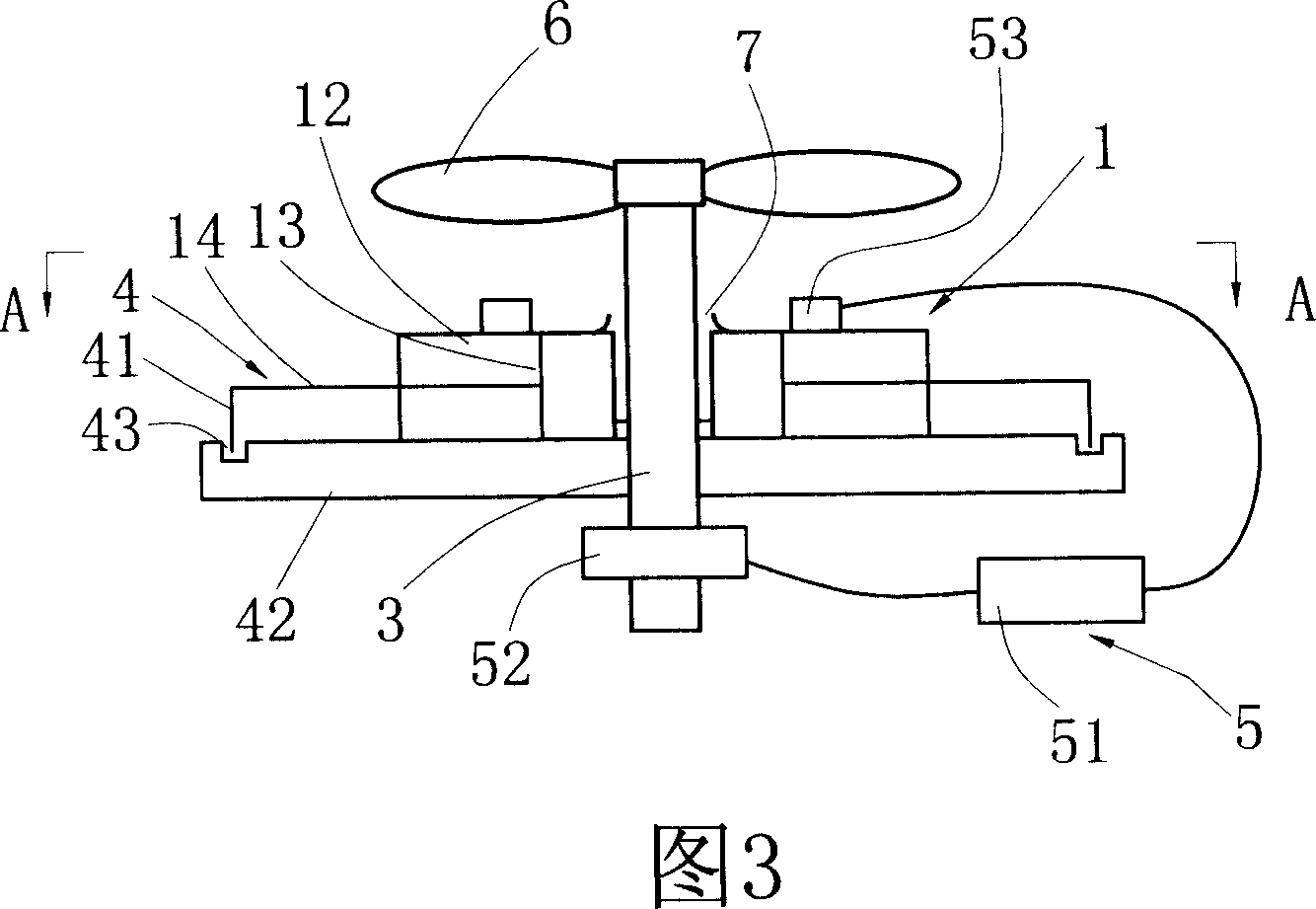

[0019] Embodiment 2: Refer to Fig. 3 and Fig. 4 .

[0020] As can be seen from Fig. 3 and Fig. 4, compared with Embodiment 1, the cylinders 12 of this embodiment have been located on the top of the cylinder block 11, running in a horizontal state, and the rotor 42 is below the cylinder block 11. Above the seat 11, the wave-shaped transmission rail 43 is on a horizontal plane. This shows that the angle between the axis line of the cylinder and the rotor can be arbitrary, as long as the cylinder can drive the rotor through the transmission rod, any positional relationship in which the rotor outputs power through the output shaft is all possible. The greatest advantage of the present invention is compact structure, easy optimization of various technical performances, and reduction of gasoline consumption.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com