Vibration reduction in large diesel engines

An engine, piston engine technology, applied in the direction of engine control, combustion engine, machine/engine, etc., can solve problems such as discomfort of crew and passengers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The invention has been described with reference to its embodiments in which a crosshead large piston engine, in particular a two-stroke engine, is mounted on a boat driven by the engine. The present invention can also be applied to other occasions.

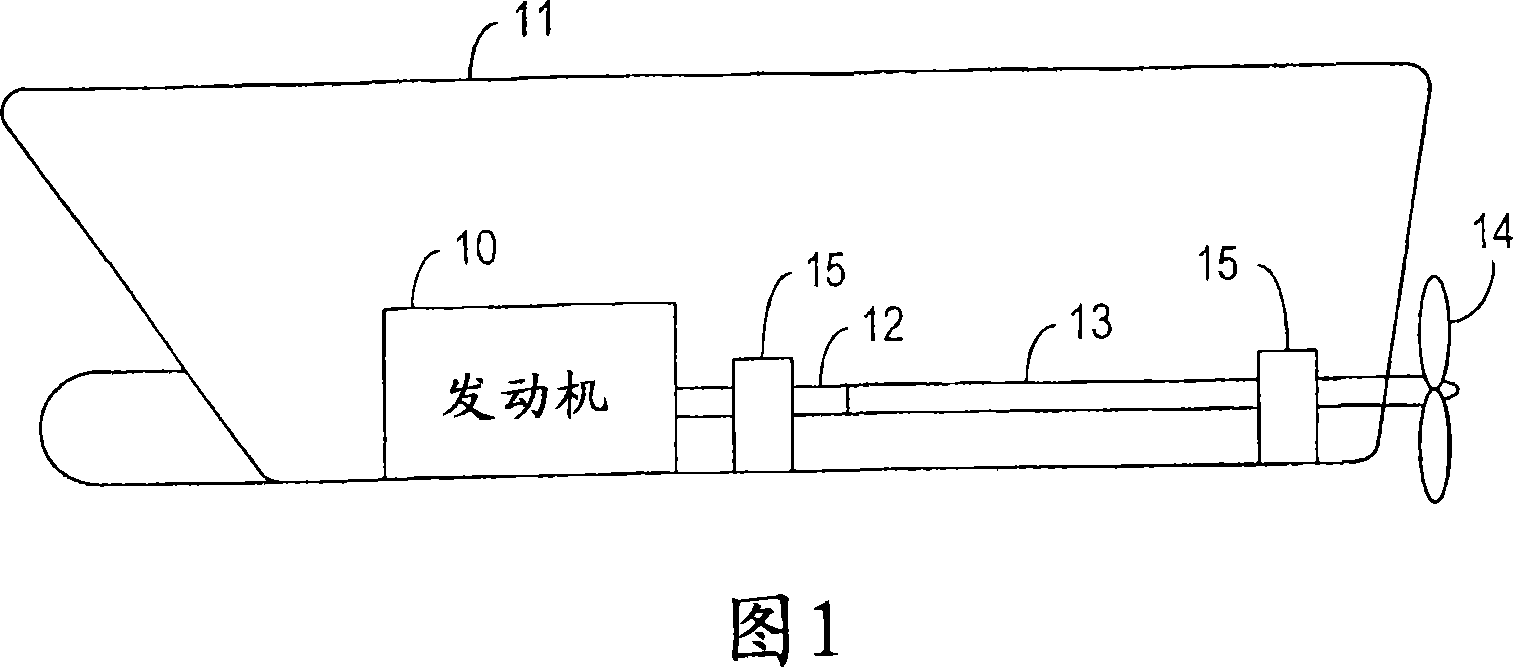

[0021] In FIG. 1 , a crosshead large piston engine 10 , in particular a two-stroke engine, is mounted on a ship 11 , which is only schematically represented. The engine 10 has an engine output shaft 12 which drives a load, for example a propeller 14 driven via a drive shaft 13 , and / or an electrical generator if required. The output shaft 12 and the transmission shaft 13 are supported by a shaft support 15 . Engine 10 is preferably an electronically controlled engine, a number of operating parameters of which can be controlled electronically.

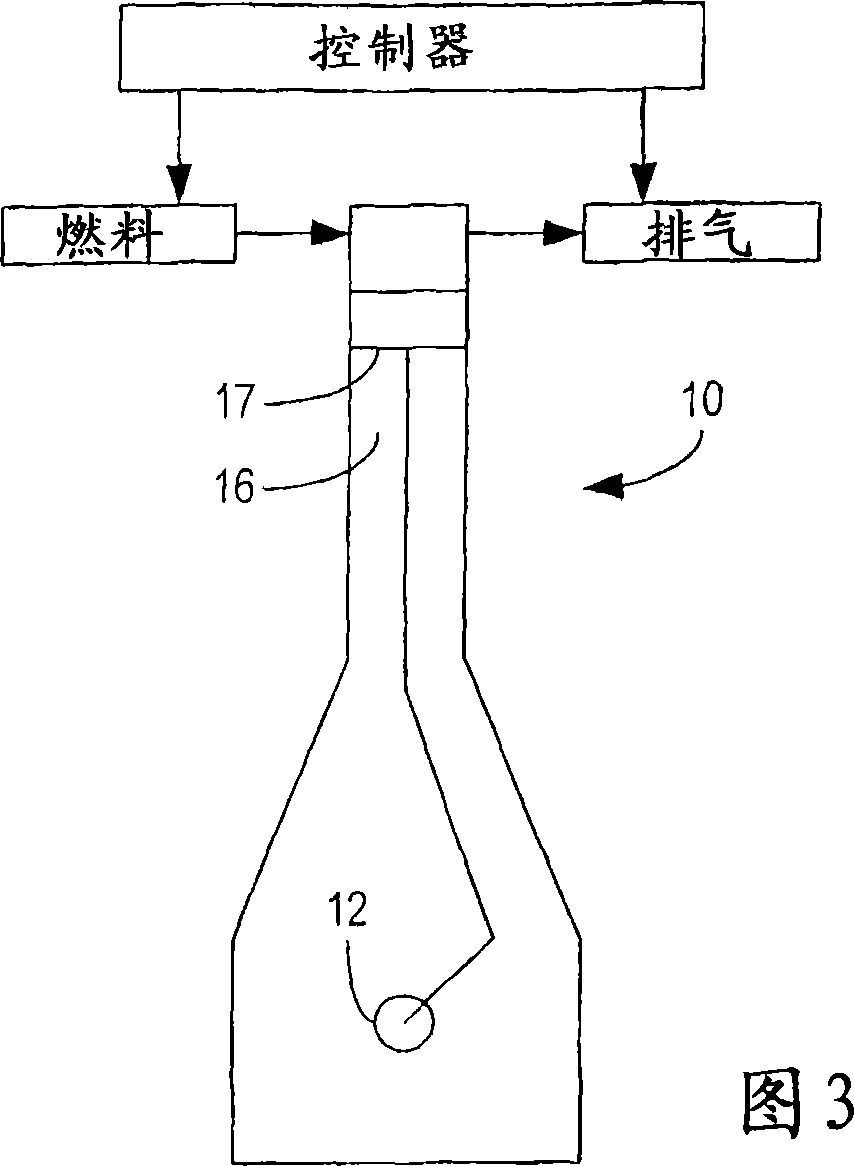

[0022] In FIG. 3 there is shown an engine 10 with a main or output shaft 12 and a cylinder 16 with a piston 17 for driving the main shaft 12 . The fuel system includes a fuel pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com