Crane

A technology for cranes and actuating cylinders, applied in the field of cranes, can solve problems such as extra stress in stroke length, and achieve long-lasting operation, low center of gravity, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

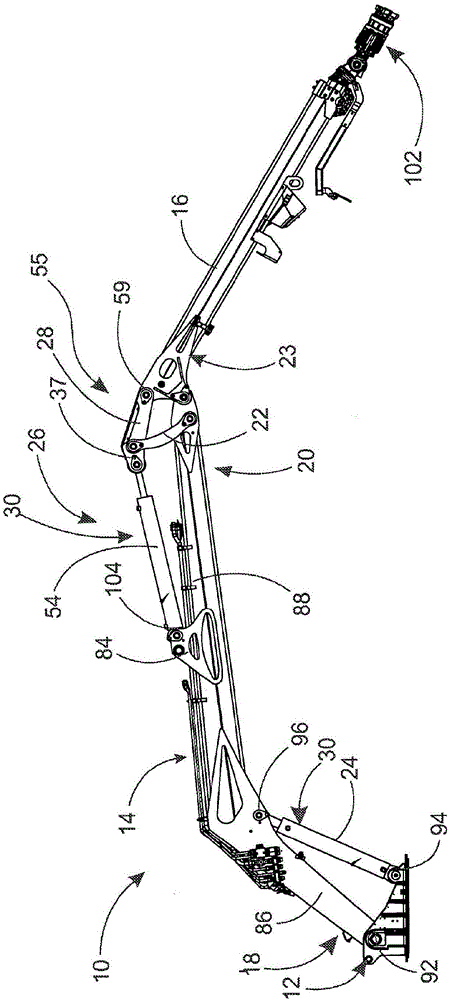

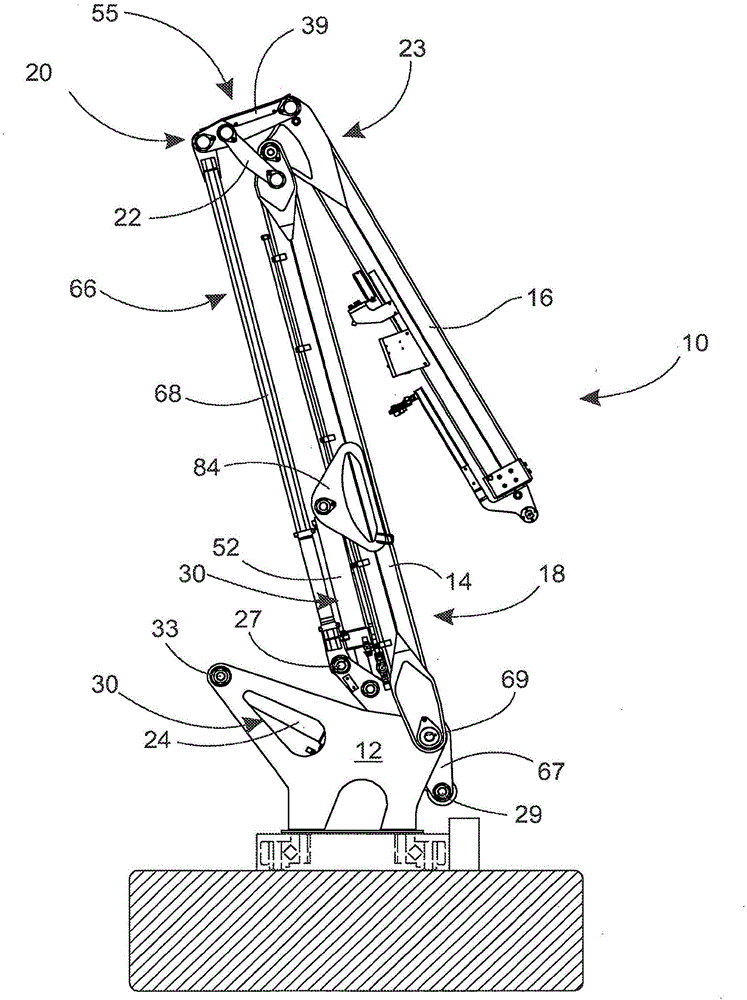

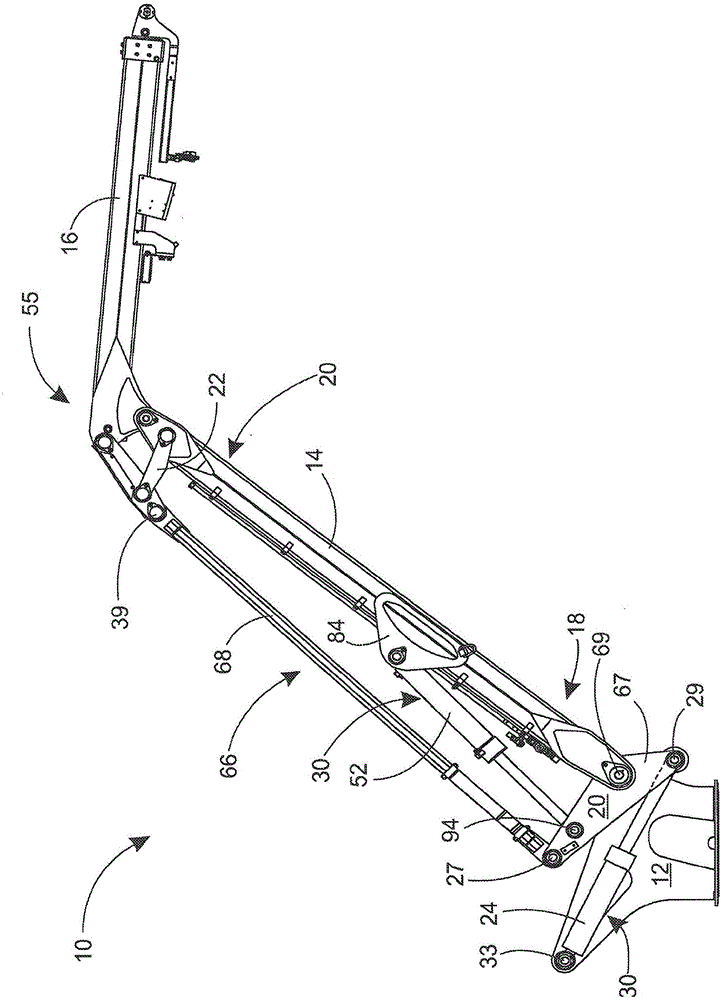

[0098] Figures 1 a and 1 b show a prior art crane 10 . The crane 10 shown in the figures is a motion path crane comprising a base 12 , a main jib 14 pivotally connected to the base 12 , an articulated jib 16 pivotally connected to the main jib 14 . Booms 14 and 16 of crane 10 are operated with the assistance of two actuating cylinders 30 , one of which is lift cylinder 24 and the other is articulation cylinder 52 .

[0099] According to FIGS. 1 a and 1 b , in the prior art crane 10 , the folding movement between the booms 14 and 16 is achieved by means of a mechanical arm mechanism 66 . The arm mechanism 66 comprises a lower arm 67 and a tie rod 68 with the aid of which the wide angle pivot 55 and the synchronization arm 22 are operated. According to these figures, the arm mechanism 66 makes the structure of the crane 10 very complex and difficult to design, since there are only few degrees of freedom left with respect to the different arm and pivot positions. In addition, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com