Electric stove

A technology of electric heating furnace and electric heating element, which is applied in the direction of electric heating fuel, household heating, heating fuel, etc. It can solve the problems of poor efficiency, reflected heat rays, troubles, etc., and achieve the effect of miniaturization and suppression of smoke generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention realizes the following electric furnace with a small number of parts: it can suppress the generation of smoke as much as possible, realize miniaturization, and can be easily used for cooking even in ordinary households, and can further improve thermal efficiency and increase The degree of freedom of design is large, and cleaning can also be simplified.

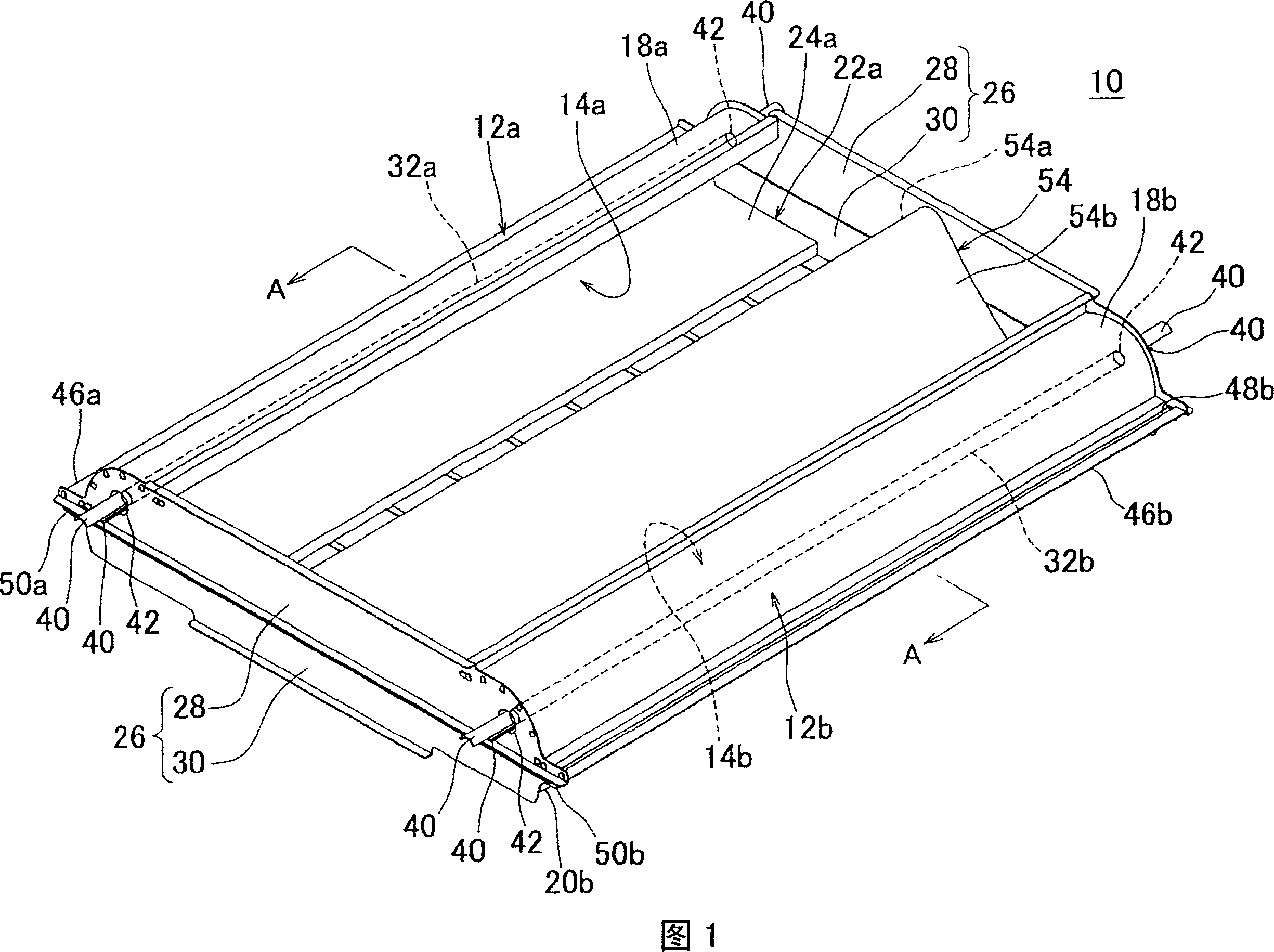

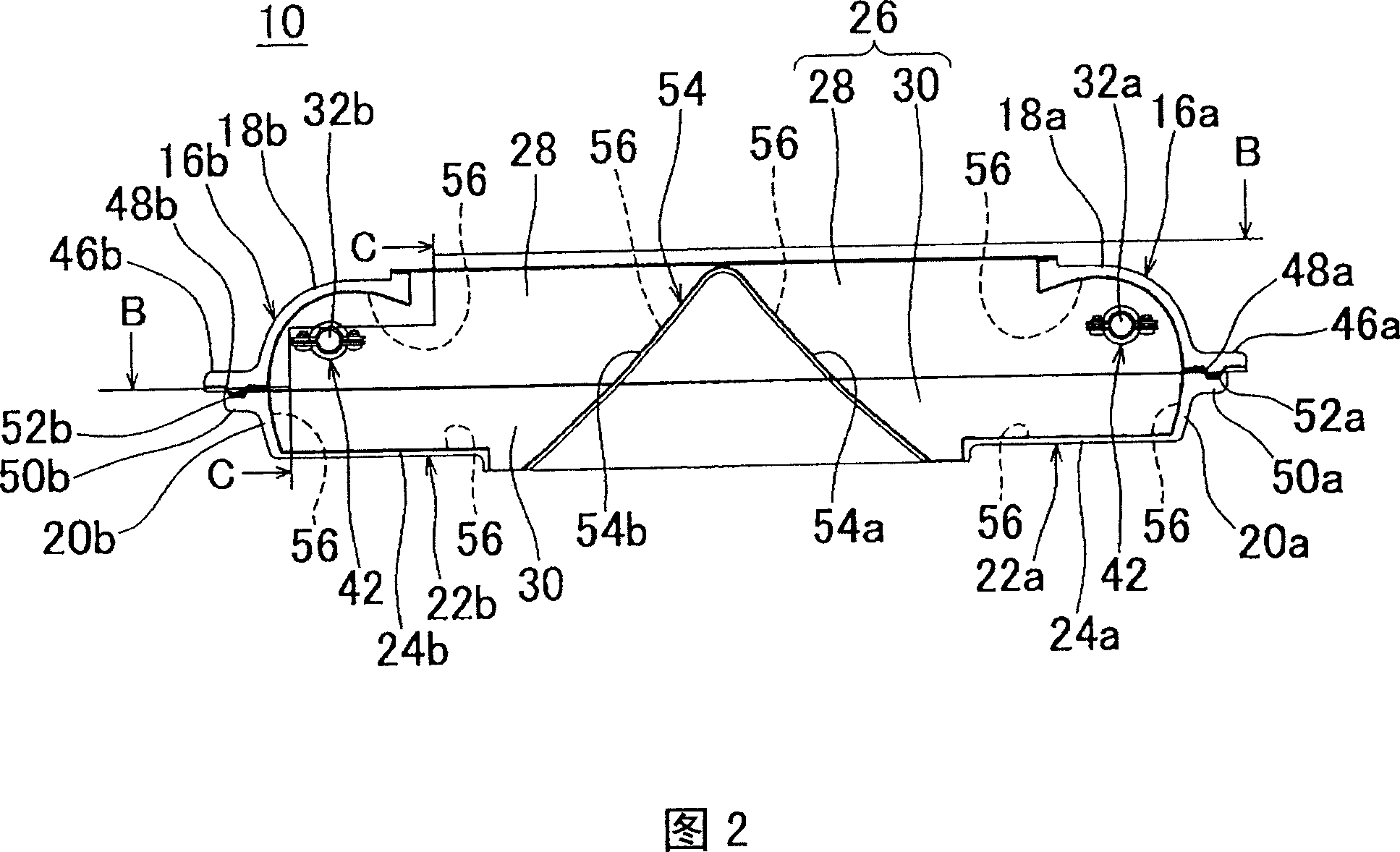

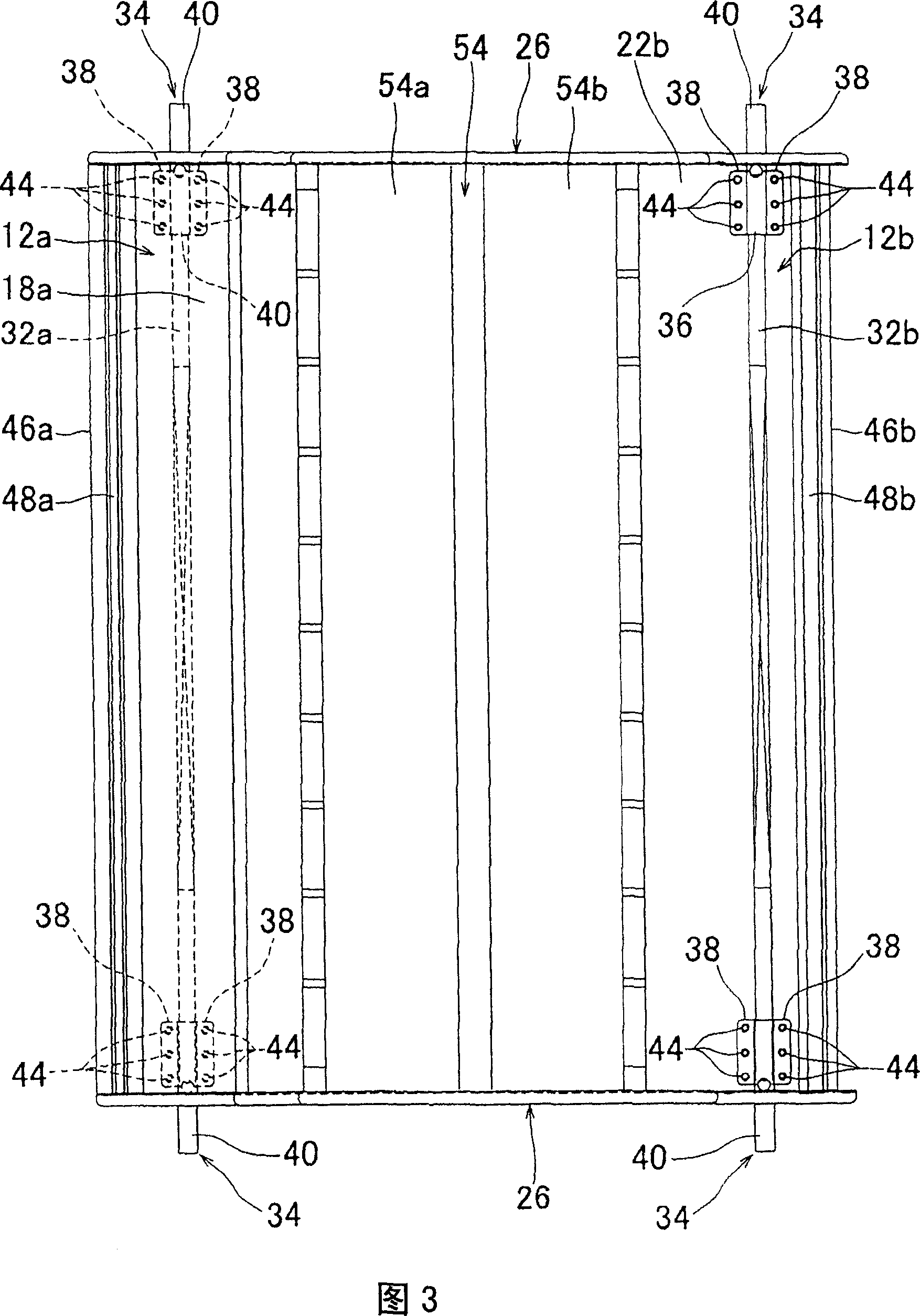

[0036] FIG. 1 is a schematic perspective view showing an example of an embodiment of the present invention, and FIG. 2 is a schematic cross-sectional view taken along line A-A of FIG. 1 . FIG. 3 is an illustration diagram of the arrow of the line B-B in FIG. 2 , and FIG. 4 is an illustration of the diagram of the arrow of the line C-C of FIG. 2 . Figure 5 is an enlarged schematic view of the main part of Figure 2

[0037] The electric furnace 10 of the present embodiment includes two mirror portions 12a and 12b. The two mirror portions 12a and 12b are formed as plate bodies having an elliptical a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap