Method for binding paper board, package box mfg. method and package box

A cardboard pasting and manufacturing method technology, which is applied in carton/carton manufacturing machinery, packaging, transportation and packaging, etc., can solve the problems of heat resistance limitation, harsh process, damage and acceptance of goods, etc., and achieve the effect of high pasting strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

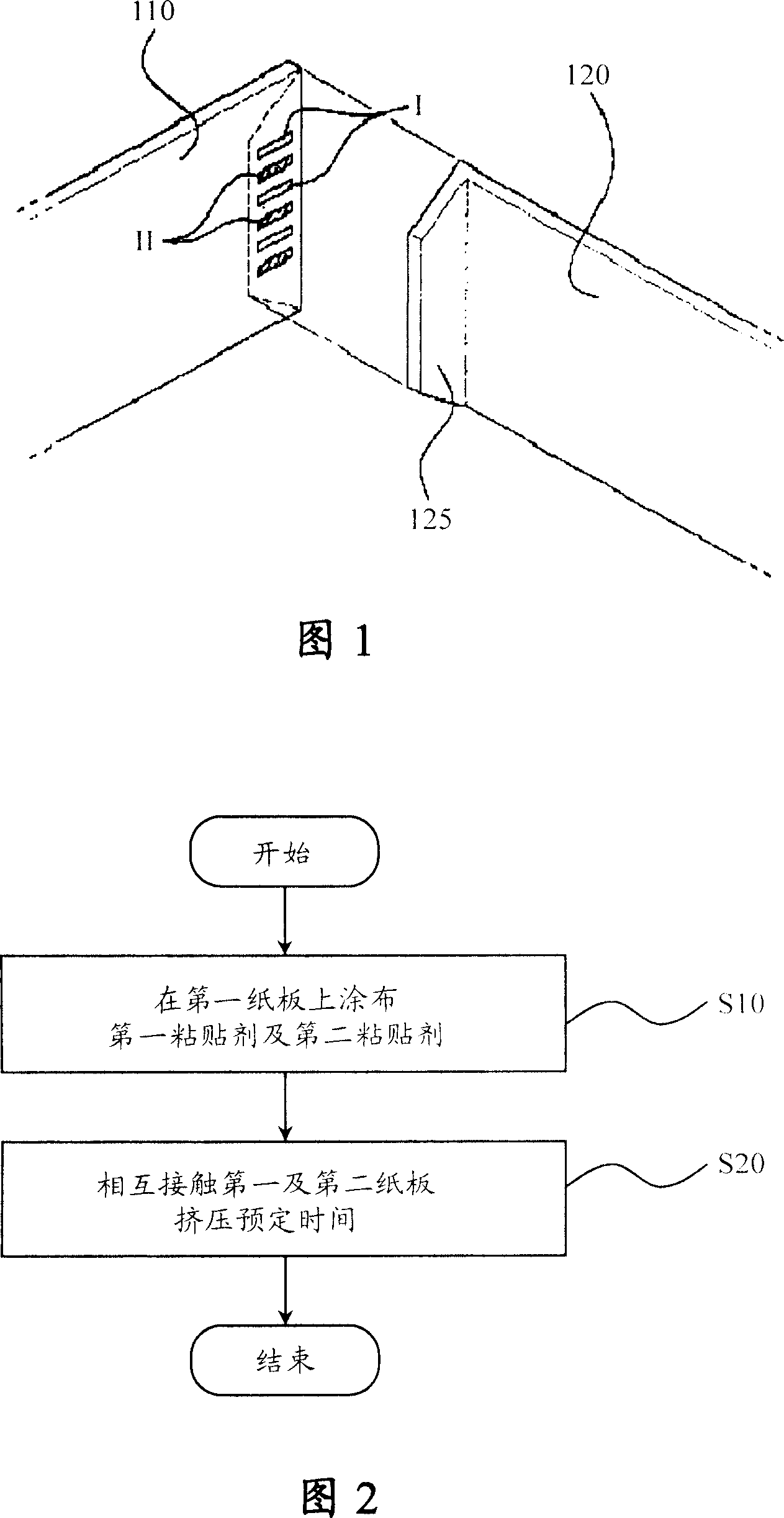

[0043] 1 is a partially enlarged perspective view illustrating a cardboard pasting method according to a first embodiment of the present invention, and FIG. 2 is a flow chart illustrating the cardboard pasting method according to the first embodiment.

[0044] Referring to FIGS. 1 and 2 , a first cardboard 110 and a second cardboard 120 are provided, and an end portion of the second cardboard 120 is folded to form an adhesive sheet 125 .

[0045] The end of the first cardboard 110 is pasted and fixed with the adhesive sheet 125 , thereby combining the first cardboard 110 and the second cardboard 120 into one body.

[0046] The first adhesive I and the second adhesive II are coated side by side on the end of the first cardboard 110 . A hot-melt adhesive was used as the first adhesive I, and an aqueous emulsion adhesive polysol was used as the second adhesive II. The first adhesive 1 hot-melt adhesive is a solid adhesive, which has fluidity in the state of heating and melting, ...

Embodiment 2

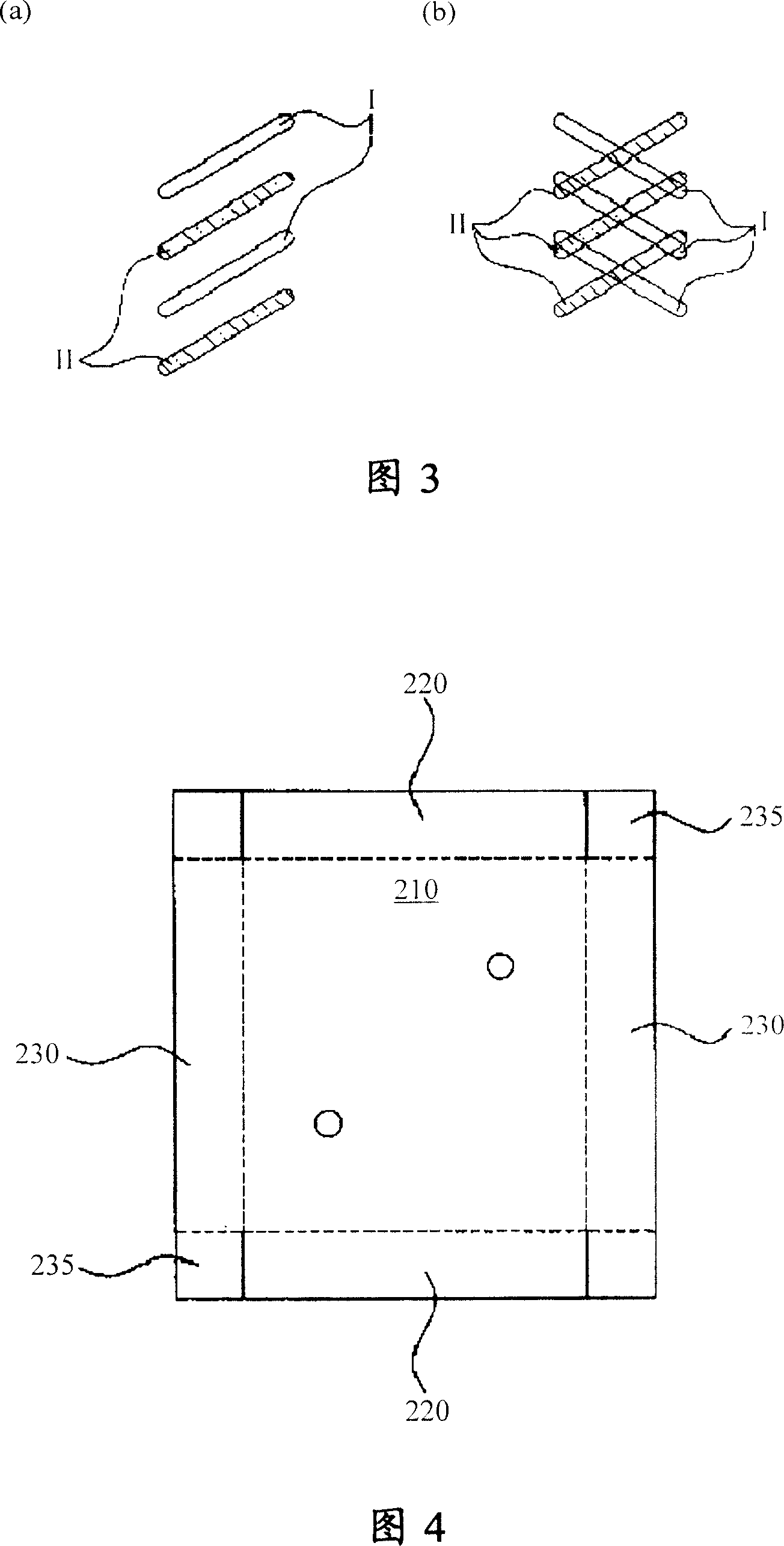

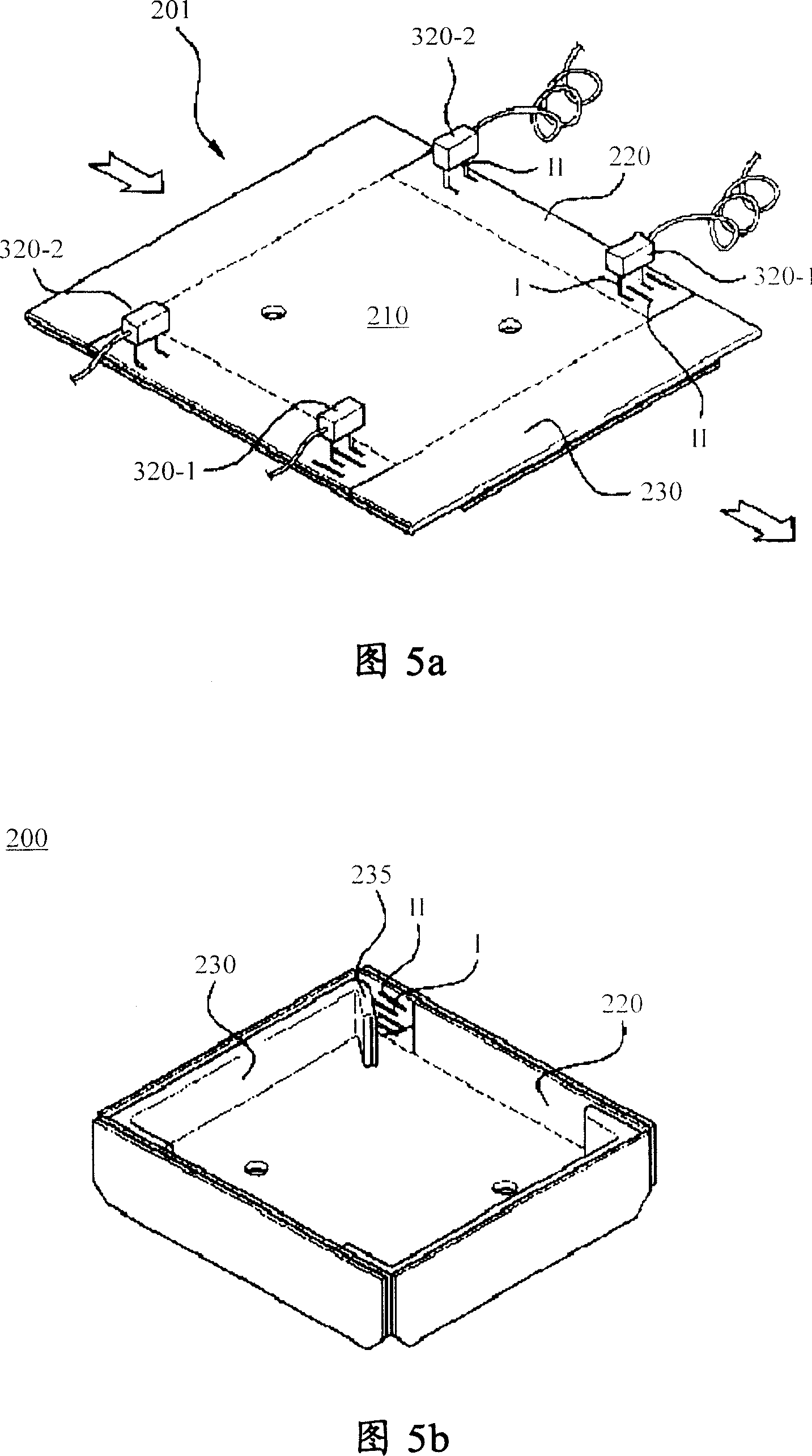

[0051] 4 is a front view of a mother board illustrating a packaging box and its manufacturing method according to a second embodiment of the present invention, and FIGS. 5a and 5b are perspective views illustrating the packaging box and its manufacturing method according to the second embodiment.

[0052] Referring to FIGS. 4 to 5 a , the packaging box 200 includes a bottom plate 210 and side wall portions provided by a motherboard 201 in the shape of an expanded view. The motherboard 201 includes a bottom plate 210 , a first side wall portion 220 and a second side wall portion 230 . The bottom plate 210 is formed at the center of the motherboard 201 , and the four sides of the quadrangular shape are connected to the first and second side walls 220 , 230 along fold lines. That is, the first sidewall panels 220 are formed on two facing sides of the bottom panel 210 , and the second sidewall panels 230 are formed on the remaining two facing sides of the bottom panel 210 . As me...

Embodiment 3

[0074] Fig. 7 is a perspective view illustrating a packaging box machine manufacturing method according to a third embodiment of the present invention.

[0075] The packaging box and manufacturing method according to the third embodiment utilize the packaging box 200 according to the second embodiment, and the manufacturing method described in the second embodiment can be continued. For the convenience of description, the packaging box and its manufacturing method according to this embodiment refer to the drawings and descriptions of the previous embodiment.

[0076] Referring to FIG. 7 , the packing box 200 forms side walls with a first side wall panel 220 and a second side wall panel 230 . A divider 240 is provided inside the packaging box 200 to divide the inner space, and both ends of the divider 240 are pasted on the inner surface of the first side wall 220 . The divider 240 includes a divider center plate 242 in the center and divider sticking sheets 244 formed at both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com