Heating-power expansion valve

A technology of thermal expansion valve and valve body, applied in the field of thermal expansion valve, can solve the problems of insufficient welding reliability, difficult welding state, insufficient welding strength, etc., and achieve the effects of avoiding poor welding, avoiding insufficient strength, and ensuring insufficient strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

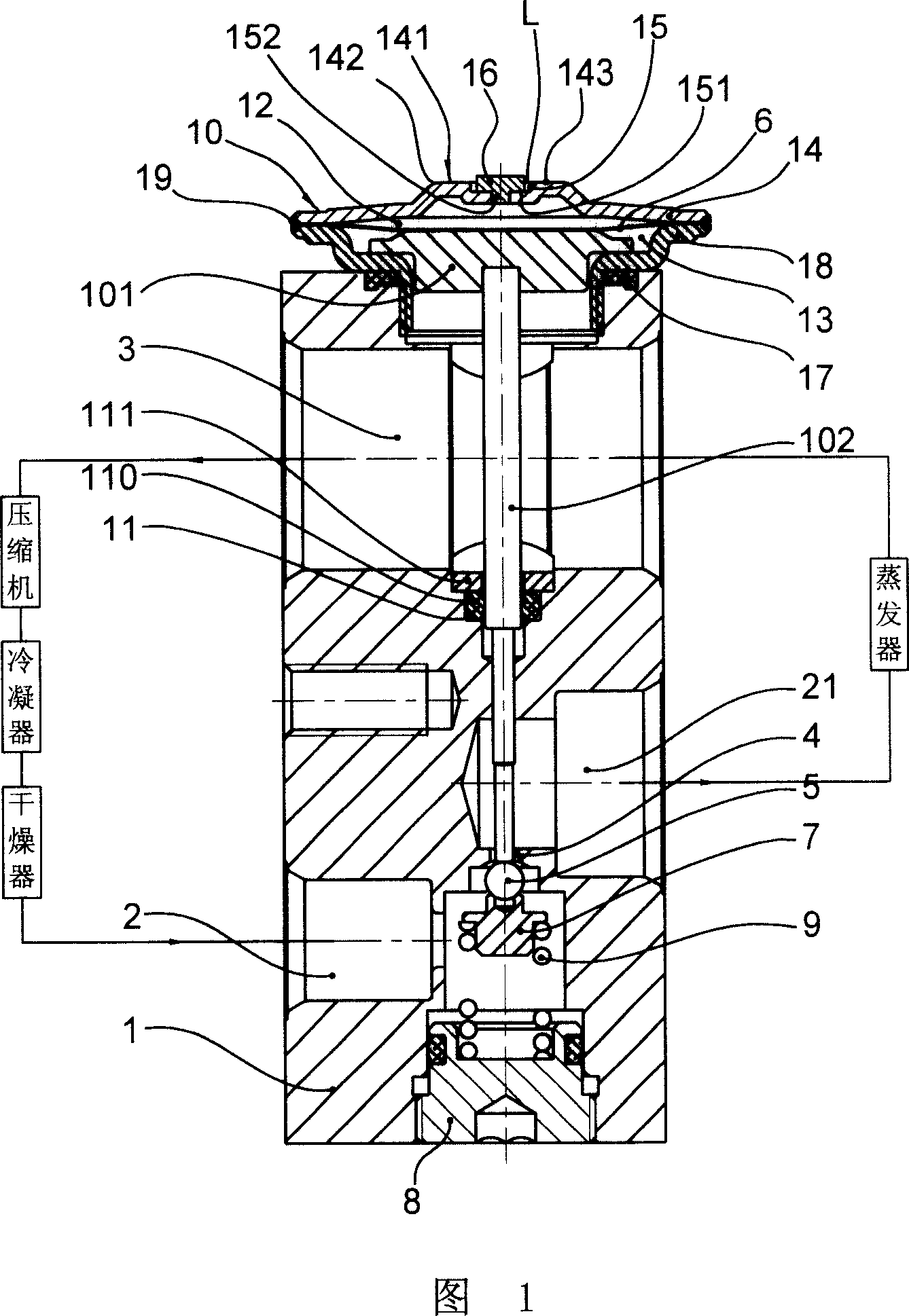

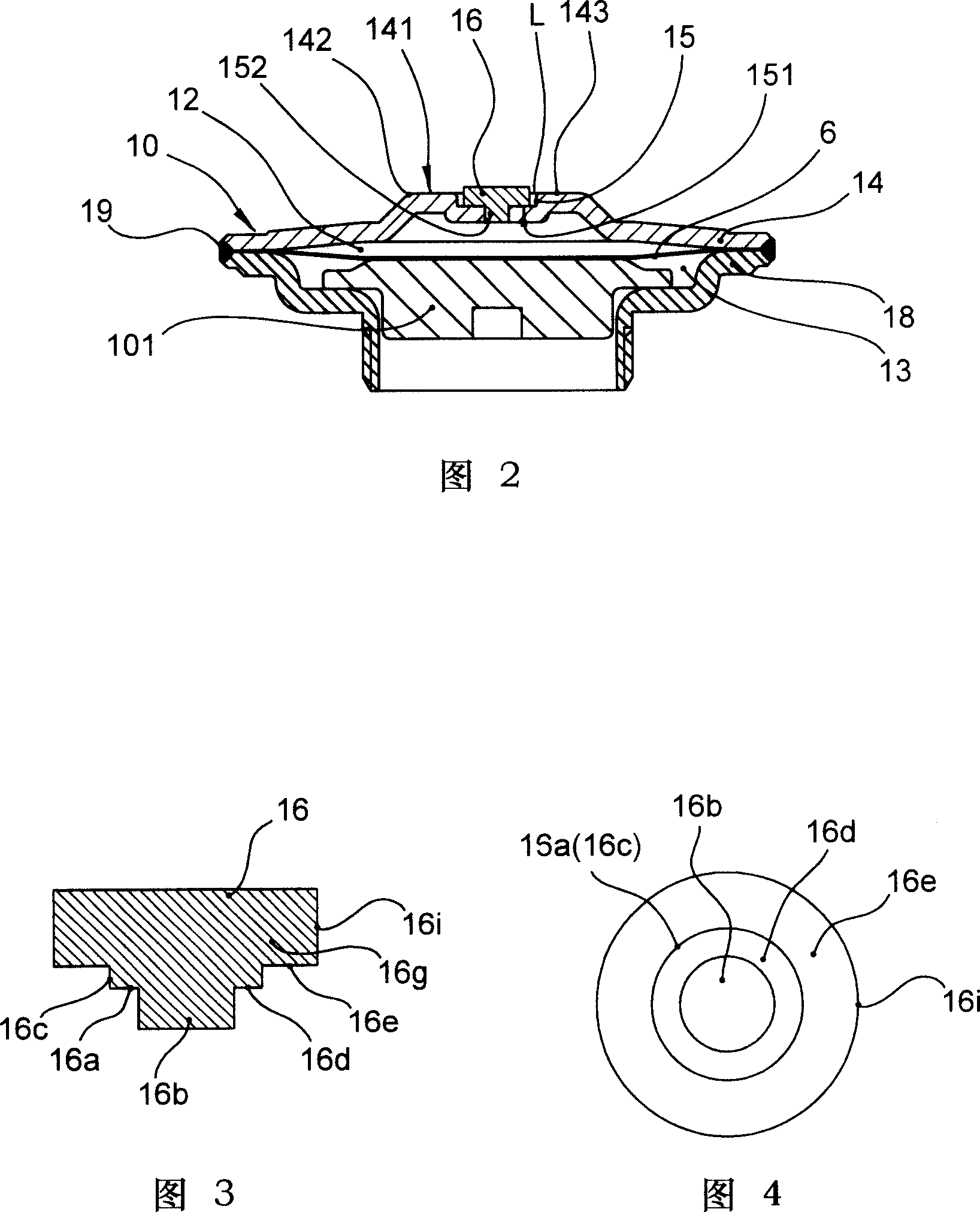

[0041] FIG. 1 depicts a thermal expansion valve installed in a refrigeration cycle in a vehicle air conditioner or the like. The valve body 1 is provided with a high-pressure refrigerant flow path 2 through which the liquid refrigerant flowing into the evaporator flows and a low-pressure refrigerant flow path 3 flowing out from the evaporator. There is a valve hole formed by a small-diameter orifice in the middle of the high-pressure refrigerant flow path 2. 4. Therefore, the liquid refrigerant flowing from the accumulator (not shown) into the high-pressure refrigerant flow path 2 passes through the valve hole 4 with a relatively small flow path area and expands adiabatically, and flows into the passage 21 . The opening portion of the valve hole 4 on the refrigerant inflow side forms a valve seat, and the opening degree of the valve hole 4 is changed by approaching or separating the spherical valve element member 5 at the valve seat. The valve core part 5 is supported by the ...

Embodiment 2

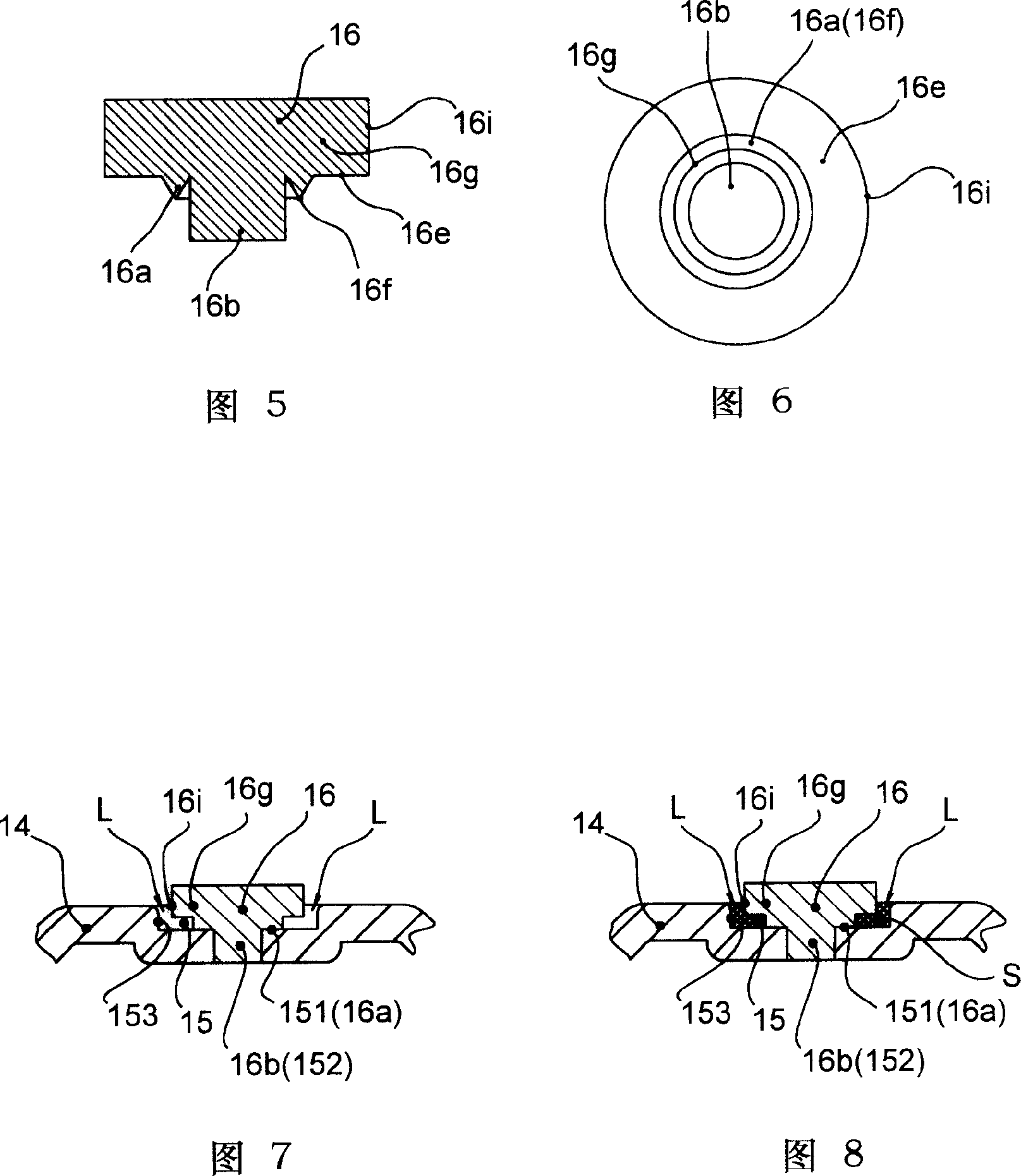

[0055] As shown in FIG. 5, a disc-shaped sealing head is provided with a protrusion 16a on its lower surface 16e, and the protrusion 16a is located around a convex portion 16b formed integrally at the central part of the surface 16e of the sealing head 16, as The edge portion 6f is integrally arranged with the head. The convex part 16b and the protruding part 16a may form a separate body from the above-mentioned head.

[0056] According to the above-mentioned head 16, the convex portion 16b of the head 16 is inserted into the hole formed on the bottom 151 of the recess 15 of the outer wall 14. In order to arrange the head 16 in the recess 15 and play a guiding role, the above-mentioned flange The front end of 6f is in contact with the bottom of the recess 15 of the outer wall 14 , and the head 16 is combined with the outer wall 14 . Therefore, the cap 16 can be stably and firmly combined with the outer wall 14 . As a result, during the resistance welding of the two, the ener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com