Arrangement in air-cooled internal combustion engine

An internal combustion engine, air inlet technology, applied in air cooling, combustion air/combustion-air handling, mechanical equipment, etc., can solve the problems of loud sound, adverse effects of operator's working conditions, etc., and achieve the effect of reducing sound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

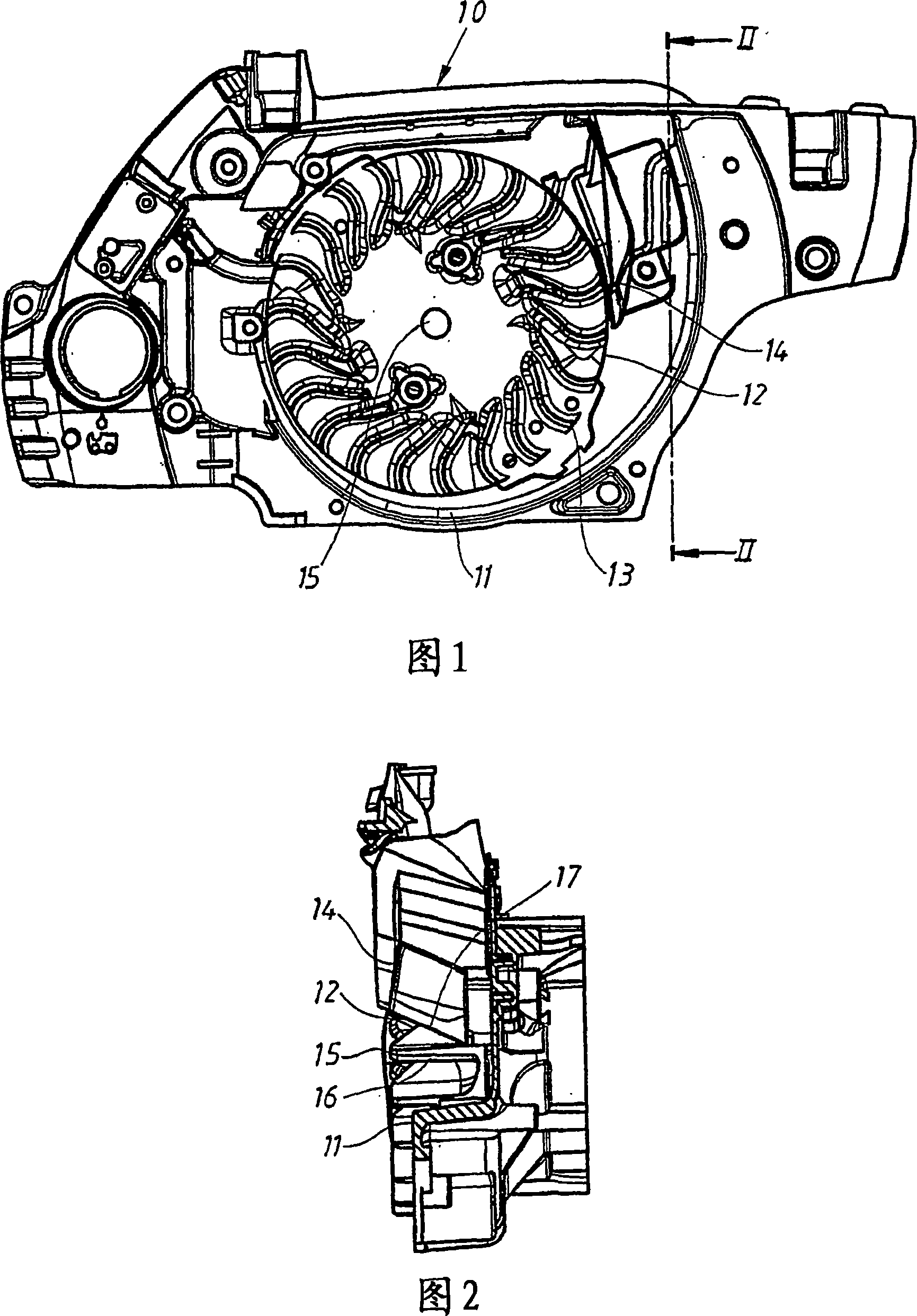

[0016] Figure 1 is a side view of the arrangement of the invention for use in a chainsaw, showing only a section 10 of the chainsaw body. A fan shroud surrounding the arrangement is not shown in the figure. The chain saw segment 10 includes a fan housing 11 and a fan wheel 12 . The fan wheel 12 rotates about an axis 15 and is equipped with vanes 13 . The fins are S-shaped and extend substantially radially of the fan wheel. Each fin 13 has an outer edge 16 substantially parallel to the axis of rotation 15 . The shape and number of fins 13 are selected to meet the specific application requirements of the fan.

[0017] An air inlet 14 is provided near the periphery of the fan wheel 12 . The air inlet 14 is positioned such that the air inlet 14 collects as much air as possible. The majority of the generated air flow turns within the fan housing 11 around the periphery of the fan wheel 12 . The air inlet 14 is therefore arranged such that the air inlet 14 exposes a large area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com