Motor control device and air-conditioner using same

A motor control and motor technology, which is applied in the direction of controlling electromechanical transmissions, controlling generators, controlling electromechanical brakes, etc., can solve the problems of complex structure and high cost of motors and fans, and achieve the effect of reducing sound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

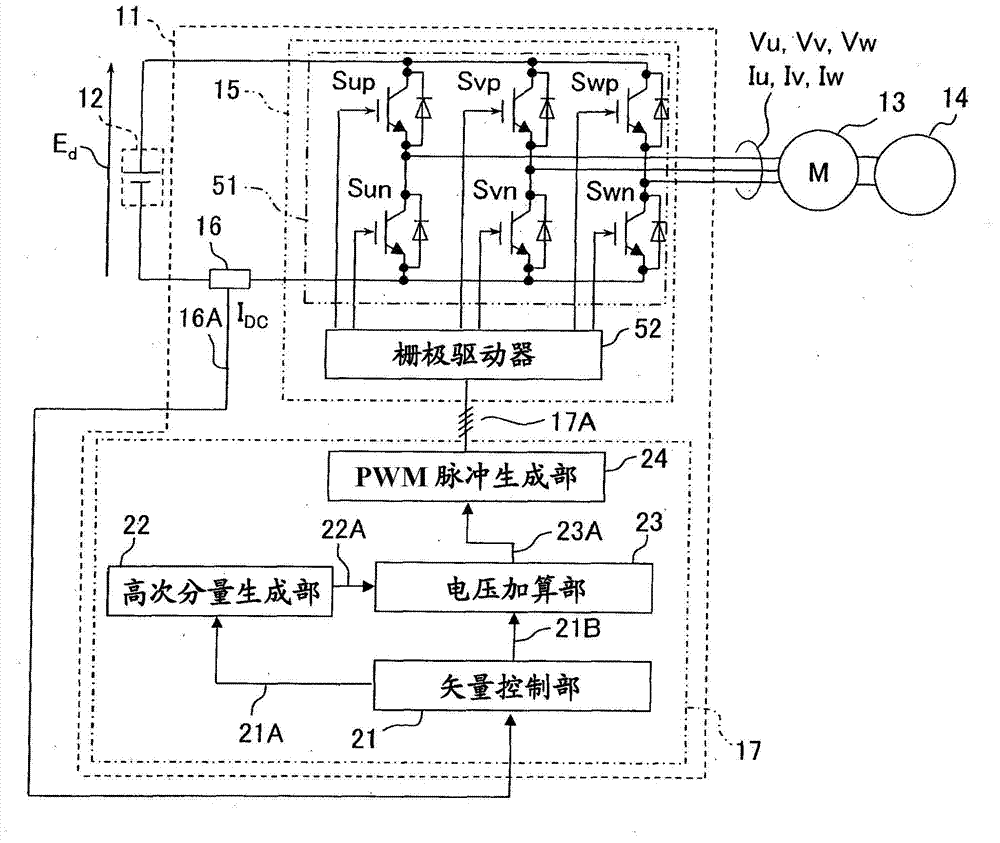

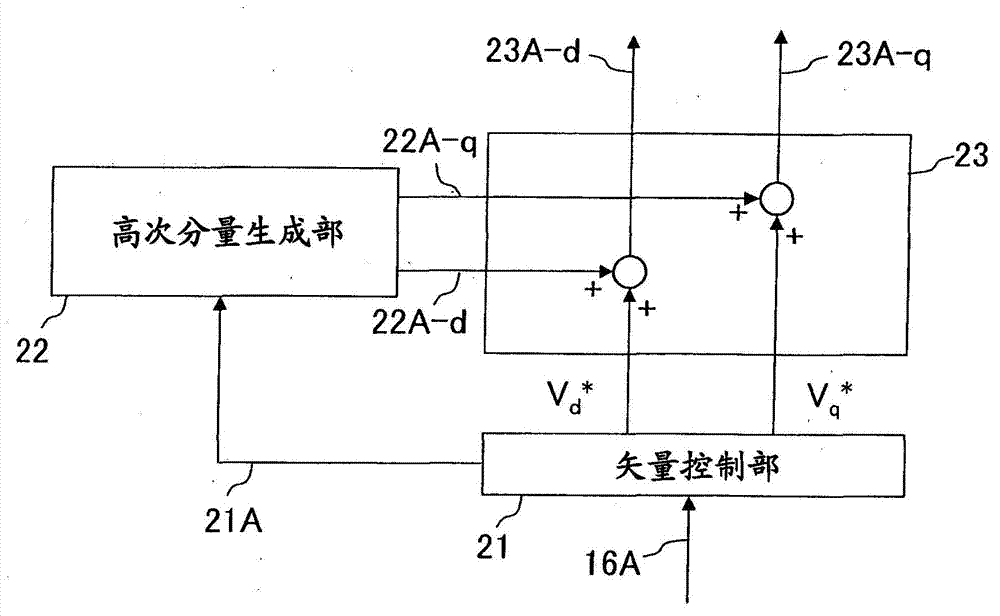

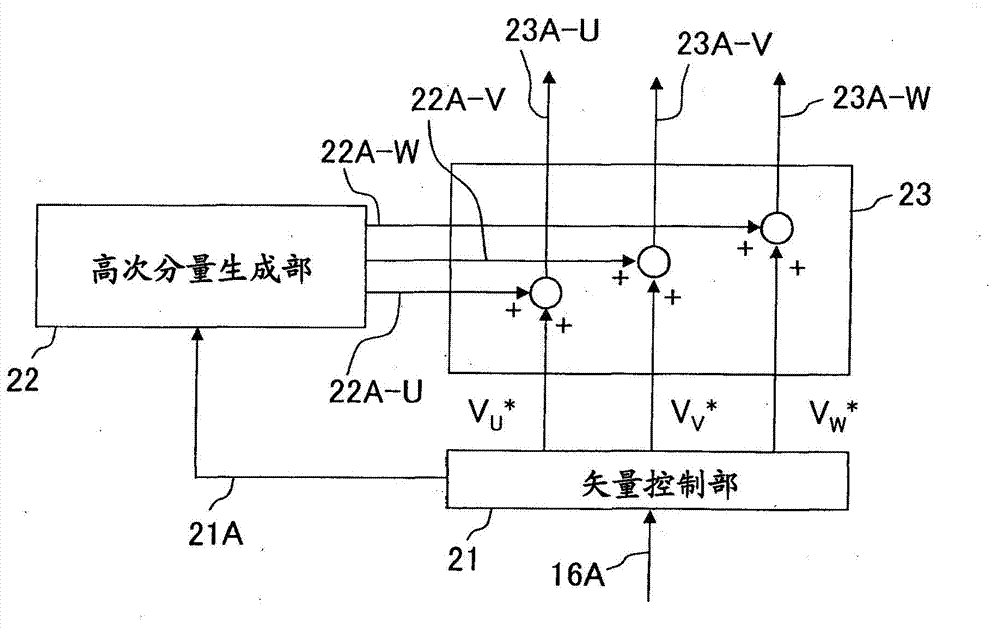

[0047] refer to Figure 1~Figure 3 A motor control device according to a first embodiment of the present invention will be described.

[0048] [Structure of the motor control unit: Part 1]

[0049] figure 1 It shows the internal structure of the motor control device 11 according to the first embodiment of the present invention, the motor control device 11, the DC power supply 12, the 3-phase AC synchronous motor (abbreviated as "motor" or "3-phase motor" as appropriate) 13, and the load (Fan) 14 associated diagrams.

[0050] exist figure 1 Among them, the motor control device 11 is configured to include an inverter 15 as a DC-DC power converter and a control device 17 that controls the inverter 15 .

[0051] In addition, the control device 17 is configured to include a PWM (Pulse Width Modulation) pulse generation unit 24 , a vector control unit 21 , a higher-order component generation unit 22 , and a voltage addition unit 23 .

[0052] The motor control device 11 of the ...

no. 2 Embodiment approach )

[0202] refer to Figure 19~Figure 23 , Figure 11 A motor control device according to a second embodiment of the present invention will be described.

[0203] In the second embodiment, the reduction of the generated ninth-order component in the case of adopting the fixed phase 60-degree switching method or the fixed phase 120-degree switching method described later as the modulation method of the PWM control of the three-phase AC motor will be described. , and then reduce the (6m+3) component (m is a positive integer) fan and motor resonance noise method.

[0204] In addition, including the stationary phase 60-degree switching method and the stationary phase 120-degree switching method described later, a method in which one phase potential is fixed at a predetermined electrical angle and the other two phases are modulated is called fixed two-phase modulation.

[0205] First, the stationary phase 60-degree switching method and the stationary phase 120-degree switching method ...

no. 3 Embodiment approach )

[0271] Below, refer to Figure 24 A motor control device according to a third embodiment of the present invention will be described.

[0272] The third embodiment includes the high-order component generation unit 22 and the voltage addition unit 23 of the first embodiment, and the modulation method selection unit 25 of the second embodiment.

[0273]

[0274] Figure 24 It is a figure which shows the internal structure of the motor control device 11 which concerns on 3rd Embodiment of this invention, and the relationship between this motor control device 11, the DC power supply 12, the 3-phase motor 13, and the fan 14.

[0275] exist Figure 24 Among them, the characteristics of the third embodiment exist in the configuration of the control device 20 of the motor control device 11 .

[0276] Moreover, for the DC power supply 12, the motor 13, the fan 14, the inverter 15, and the DC bus current detection circuit 16, because and figure 1 The first embodiment is the same as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com