Method for adjusting position of stator

An adjustment method and stator technology, applied in the manufacture of stator/rotor bodies, electromechanical devices, centering/balancing rotors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

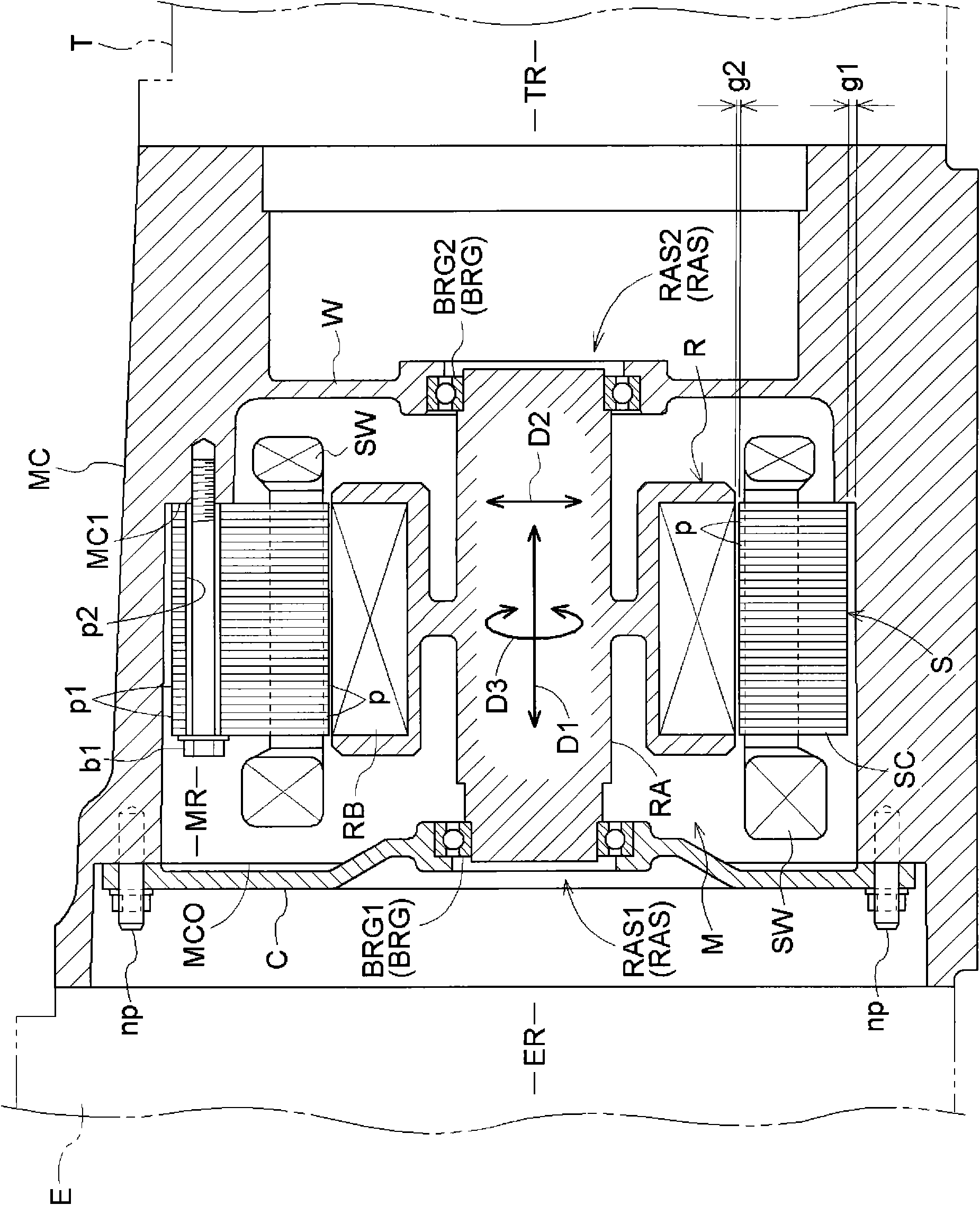

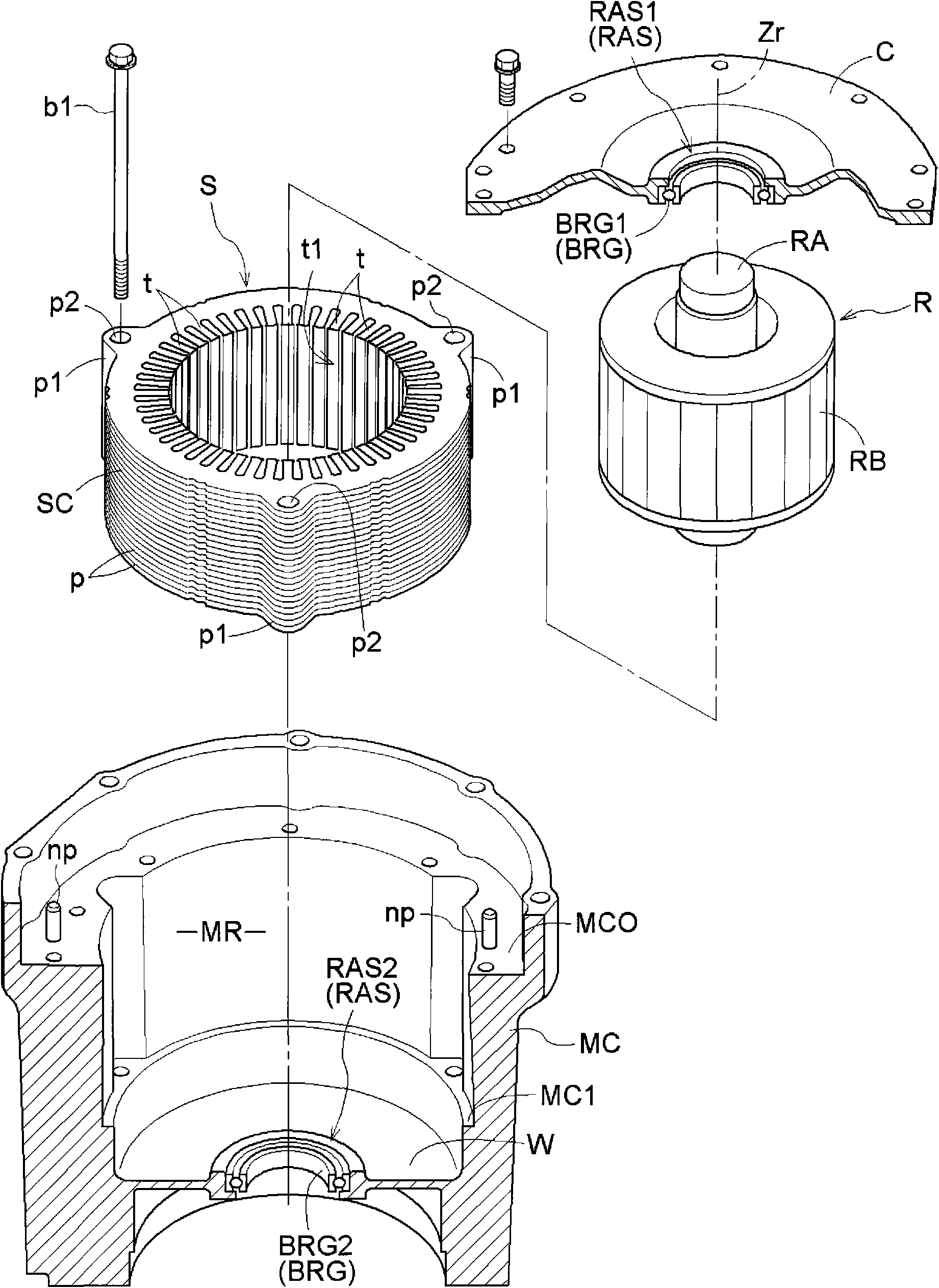

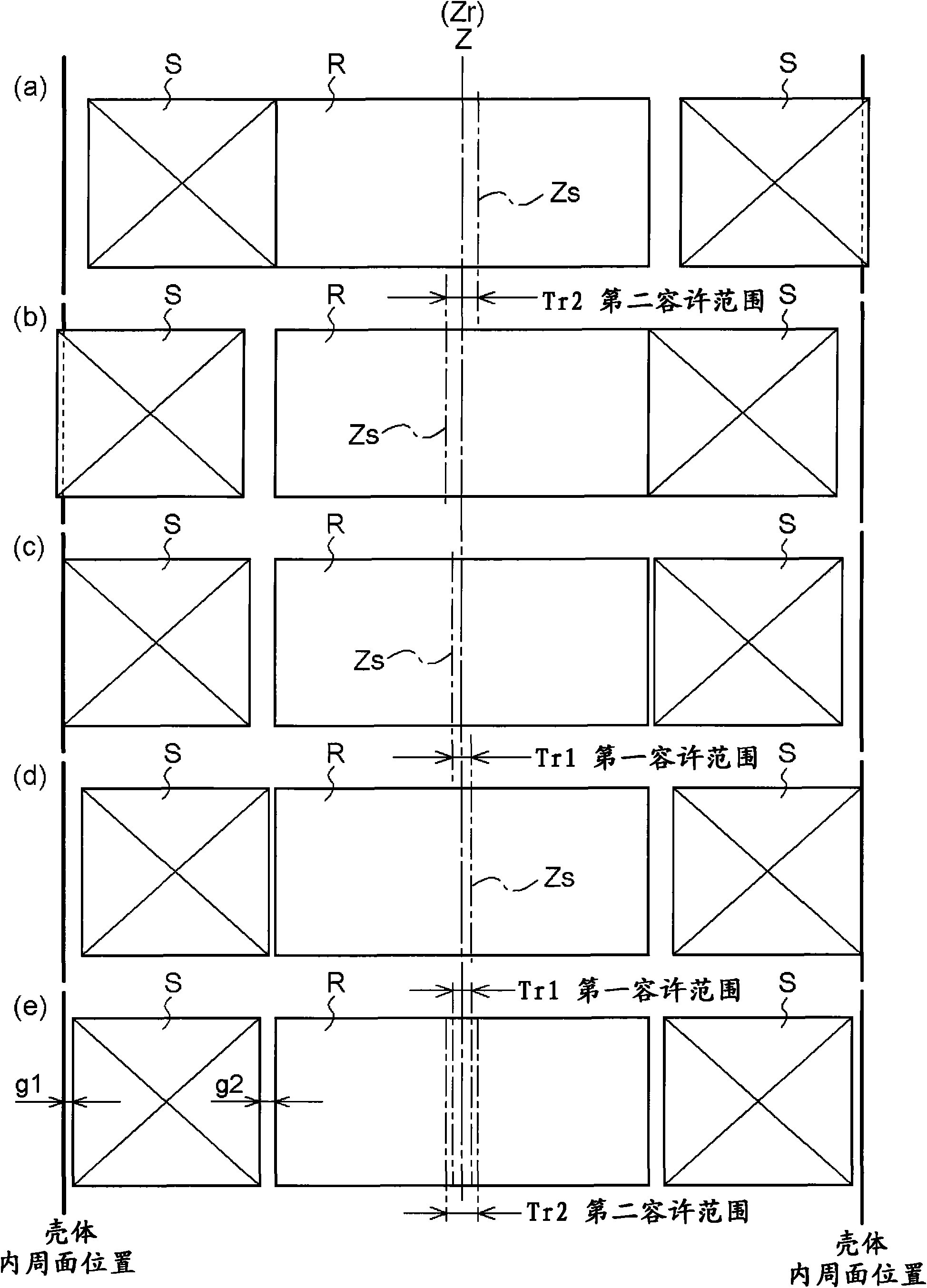

[0104] In the following description, the structure of the motor drive device M which is the object of the present application, the structure of the stator position adjustment system 100 of the present application for properly assembling the motor drive device M, and the stator S using the stator position adjustment system 100 are discussed. The position adjustment / fixing work of , and the assembly of the motor drive unit M will be described in order.

[0105] 1. Motor drive unit M

[0106] figure 1 It is a diagram showing a cross-sectional structure of a motor drive device M housed in a gearbox case MC (an example of a motor case) and in an assembled state, figure 2 It is an exploded view showing the motor drive device M in order to clarify the supporting structure of the stator S and the rotor R constituting the motor drive device M.

[0107] exist figure 1 Among them, the left side is a part on the engine room ER side where the engine E is arranged, and the right side is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com