Manufacture method of a latent heat recovery type heat exchanger

A heat recovery type, heat exchanger technology, applied in the direction of heat exchanger fixation, heat exchange equipment, manufacturing tools, etc., can solve problems such as stress corrosion cracks, achieve the effect of reducing the number of parts and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

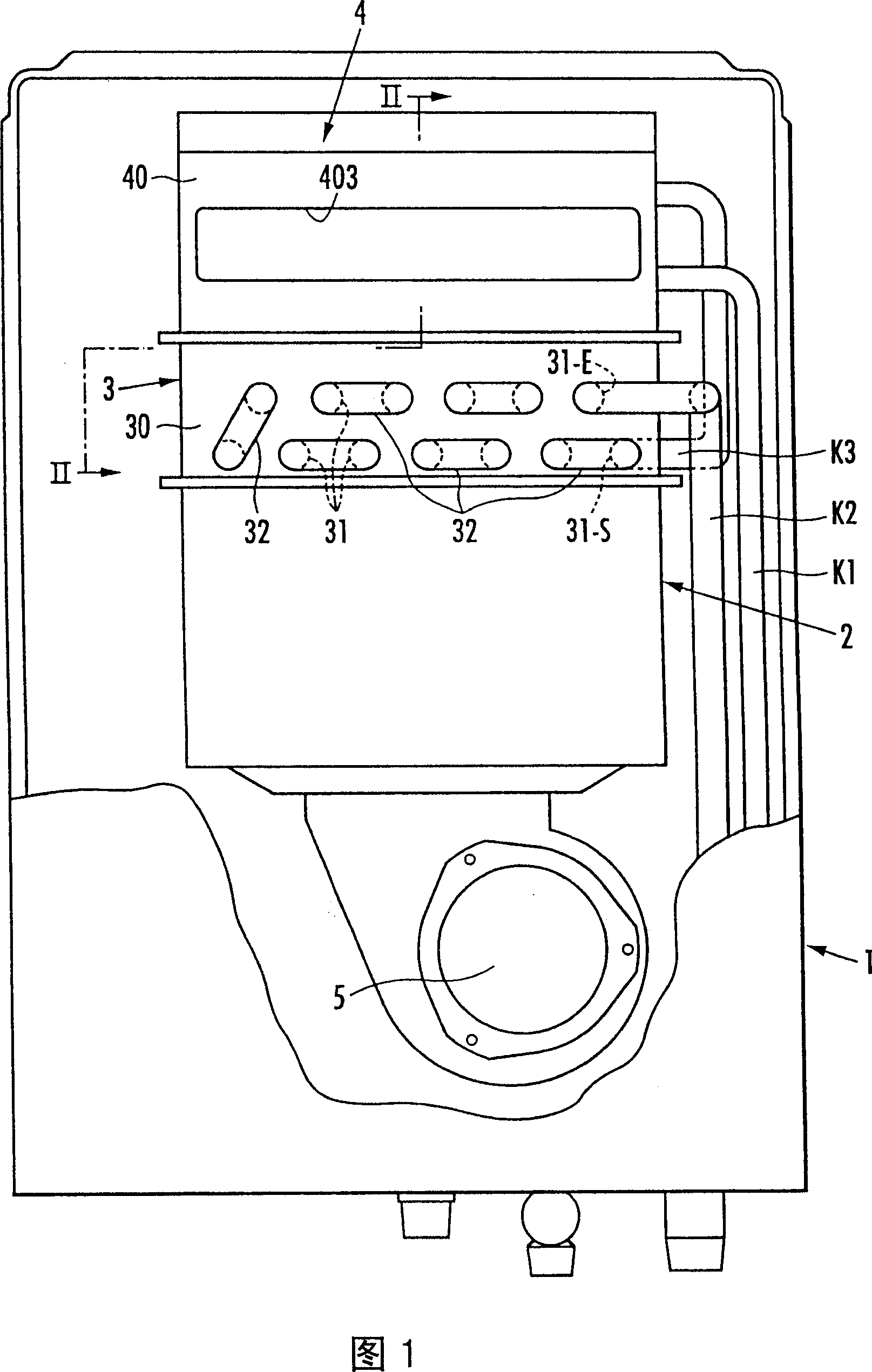

[0018] Referring to Fig. 1, 1 is the outer casing of the water heater, and the outer casing 1 is equipped with: a combustion basket 2 with a built-in burner (not shown), a main heat exchanger 3 above the combustion basket 2, and a main heat exchanger The secondary heat exchanger 4 above the device 3. In addition, a combustion blower 5 for supplying combustion air into the combustion basket 2 is arranged on the lower side of the combustion basket 2 .

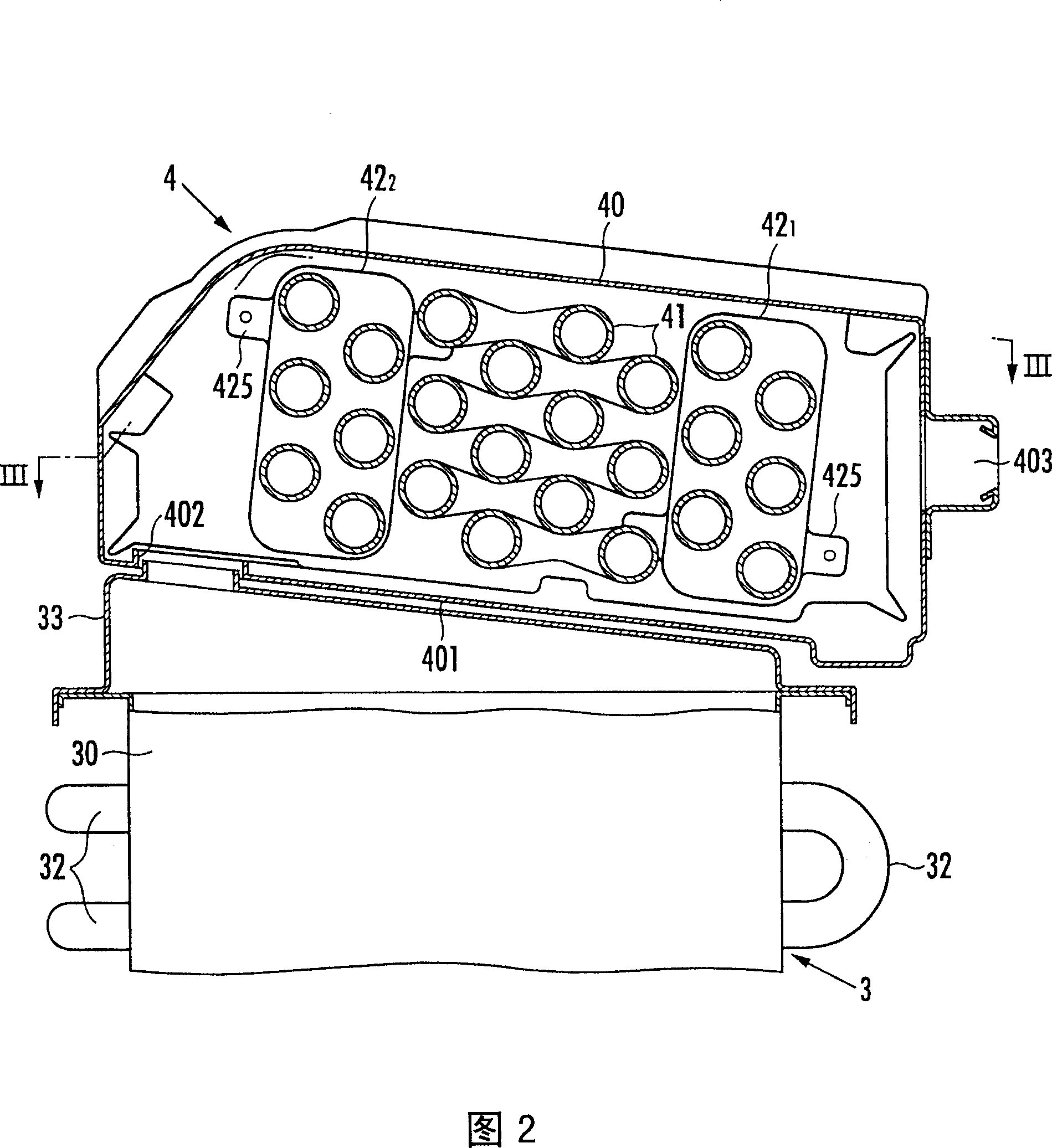

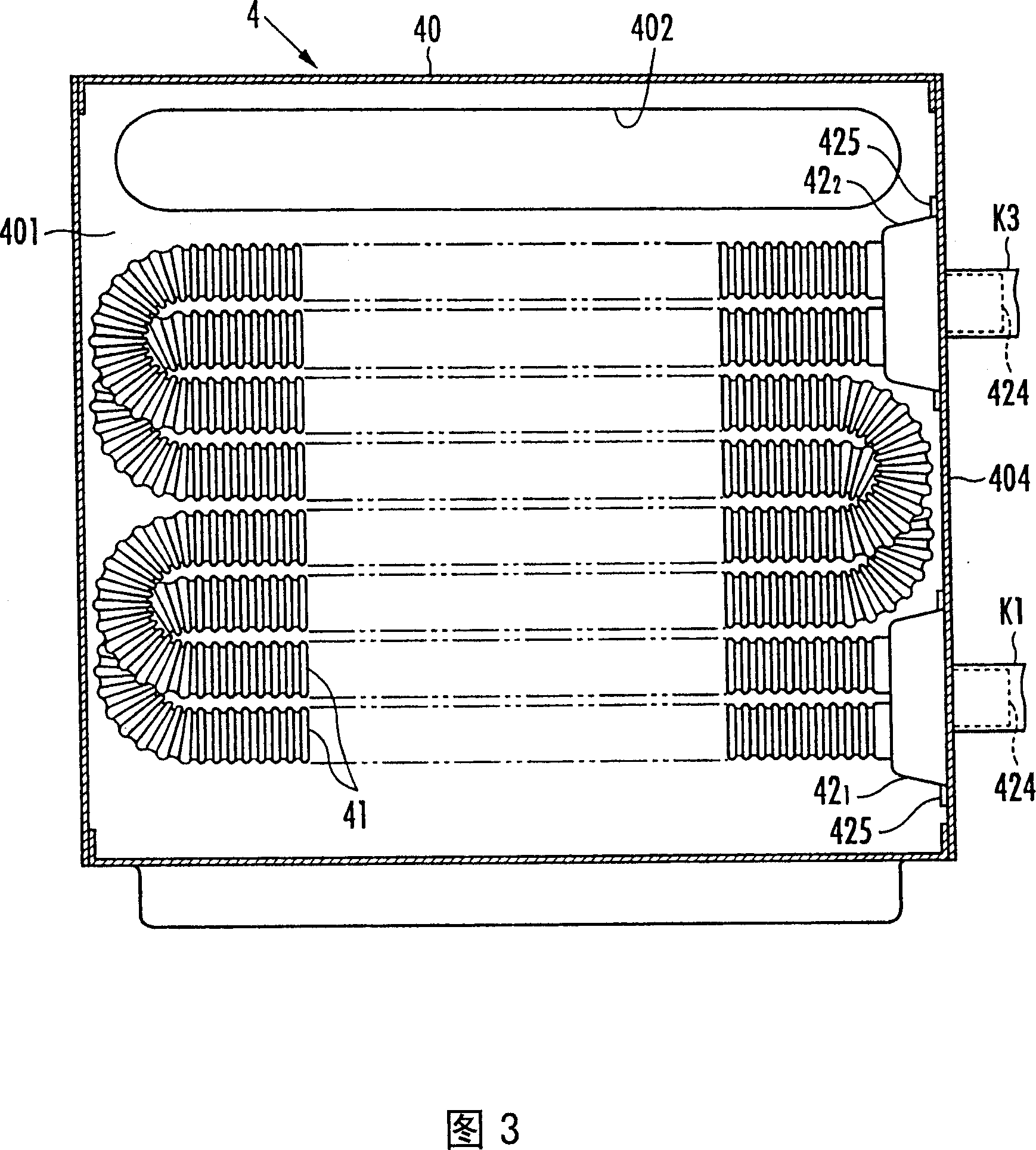

[0019] The main heat exchanger 3 is provided with a plurality of heat-absorbing fins (not shown) stacked so that there are gaps in the front-rear direction (vertical direction to the paper surface of FIG. ), a plurality of heat-absorbing pipes 31 that pass through these heat-absorbing sheets and are arranged in the longitudinal direction with the front-rear direction as its longer direction. And, on the outside of the front and rear plates of the trunk portion 30, as shown in Figure 1 and Figure 2, the heat absorption pipe 31 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com