Intermediate cooler setting structure with supercharge equipment engine

A cooler and engine technology, which is applied in the direction of engine cooling, machine/engine, power plant cooling combination layout, etc., which can solve the problems such as the wind is not easy to leak, the cooling efficiency of the intercooler is reduced, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

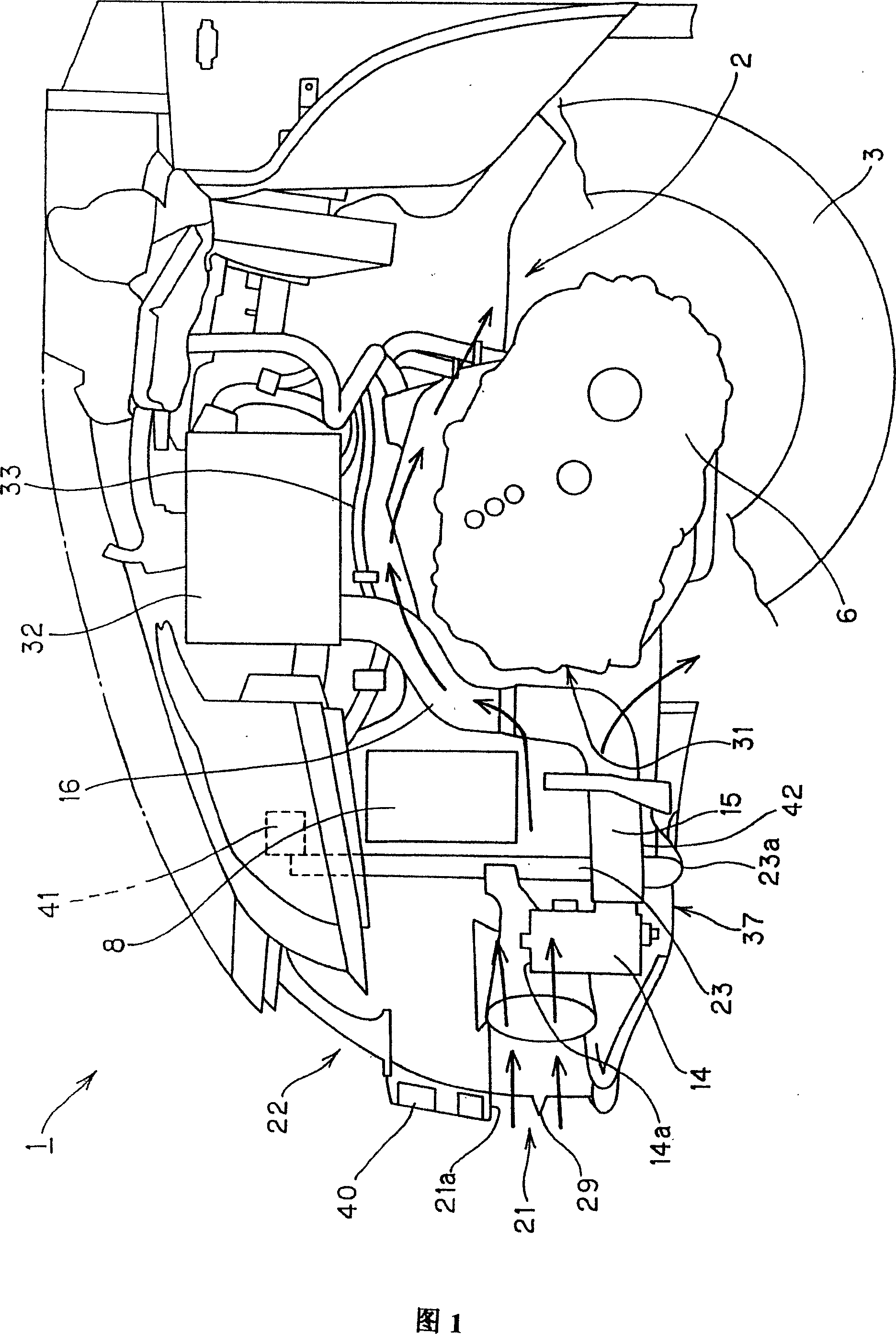

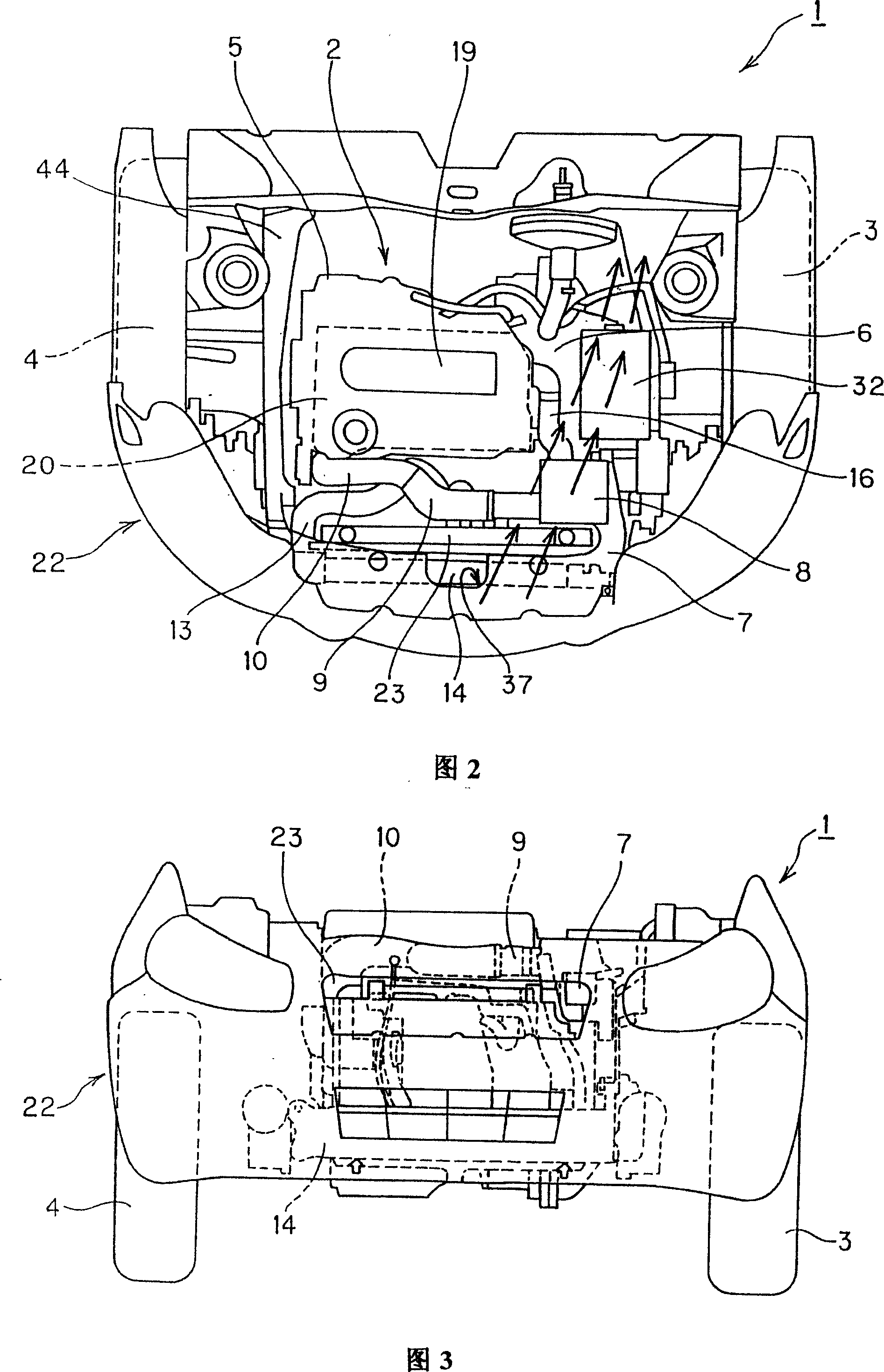

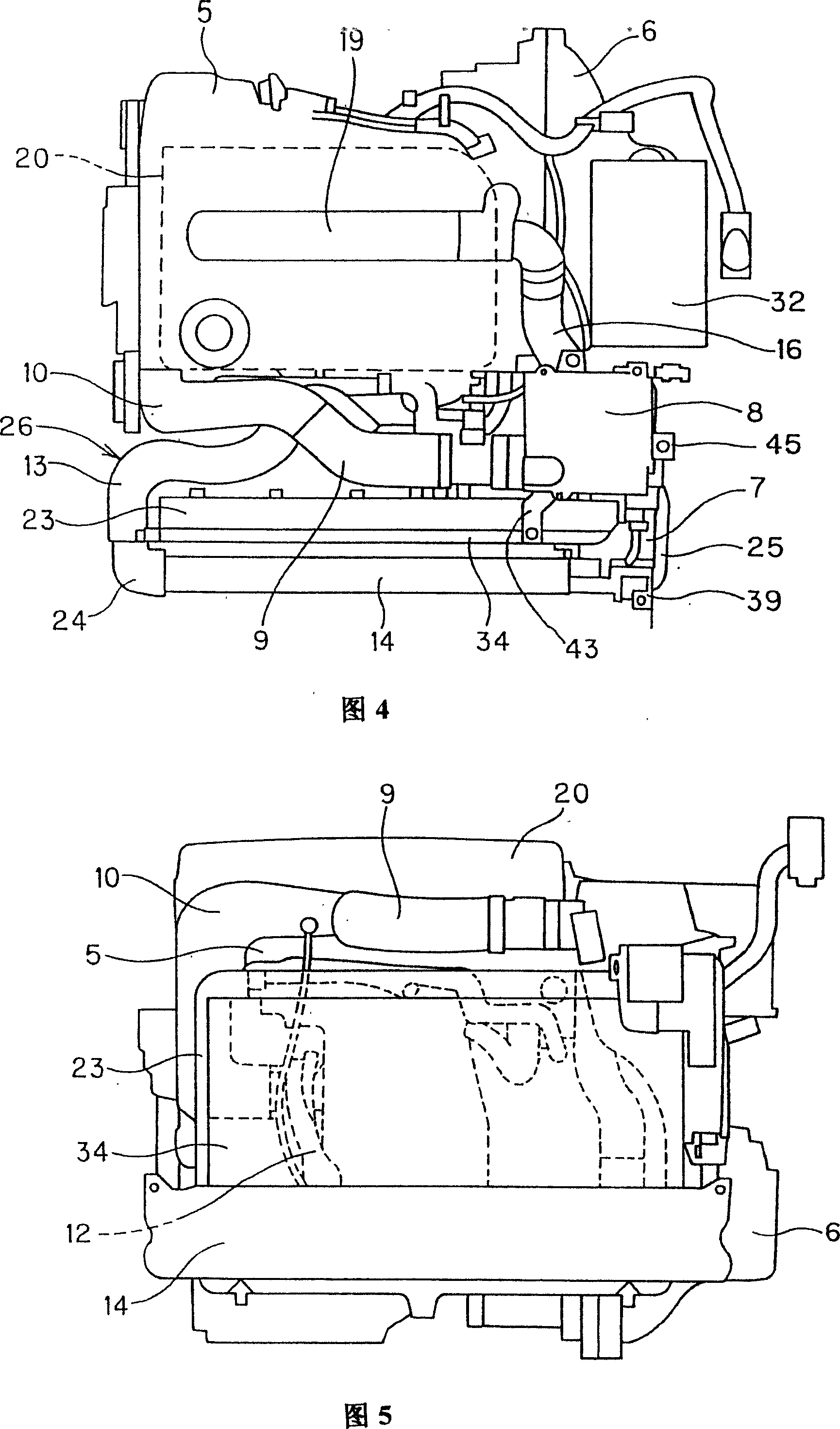

[0072] The embodiments will be described in detail below in conjunction with the accompanying drawings.

[0073] 1 to 15 show embodiments of the present invention.

[0074] 1 to 3 , 1 is a vehicle, 2 is an engine compartment formed on the front side of the vehicle 1 , 3 is a left front wheel of the vehicle 1 , and 4 is a right front wheel of the vehicle 1 .

[0075] Furthermore, in the engine room 2 of the vehicle 1, the supercharged engine 5 and the transmission 6 are arranged side by side in the vehicle lateral direction.

[0076] That is, as shown in FIG. 2 , a supercharged engine 5 is mounted in a horizontal state in an engine room 2 of the vehicle 1 , and a transmission 6 is provided on a side of the supercharged engine 5 . At this time, the height of the transmission 6 is lower than that of the engine 5 with a supercharger, and since there are many gaps above the transmission 6 , a large amount of traveling air flows from the engine 5 with a supercharger to the transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com