X-ray manipulator

An x-ray, axial technology, applied in the field of x-ray manipulators, can solve problems affecting good edge definition, and achieve the effect of ensuring accuracy and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

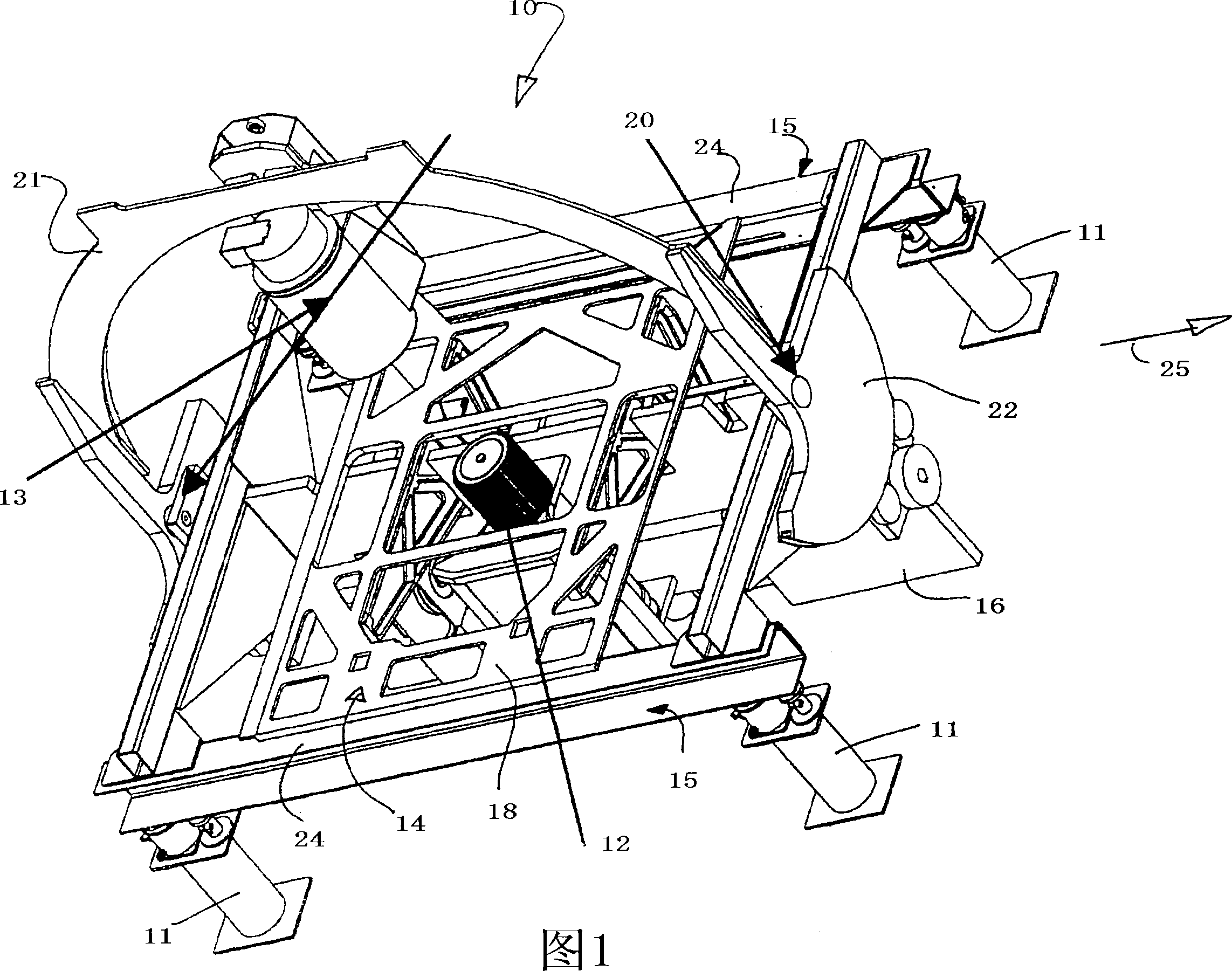

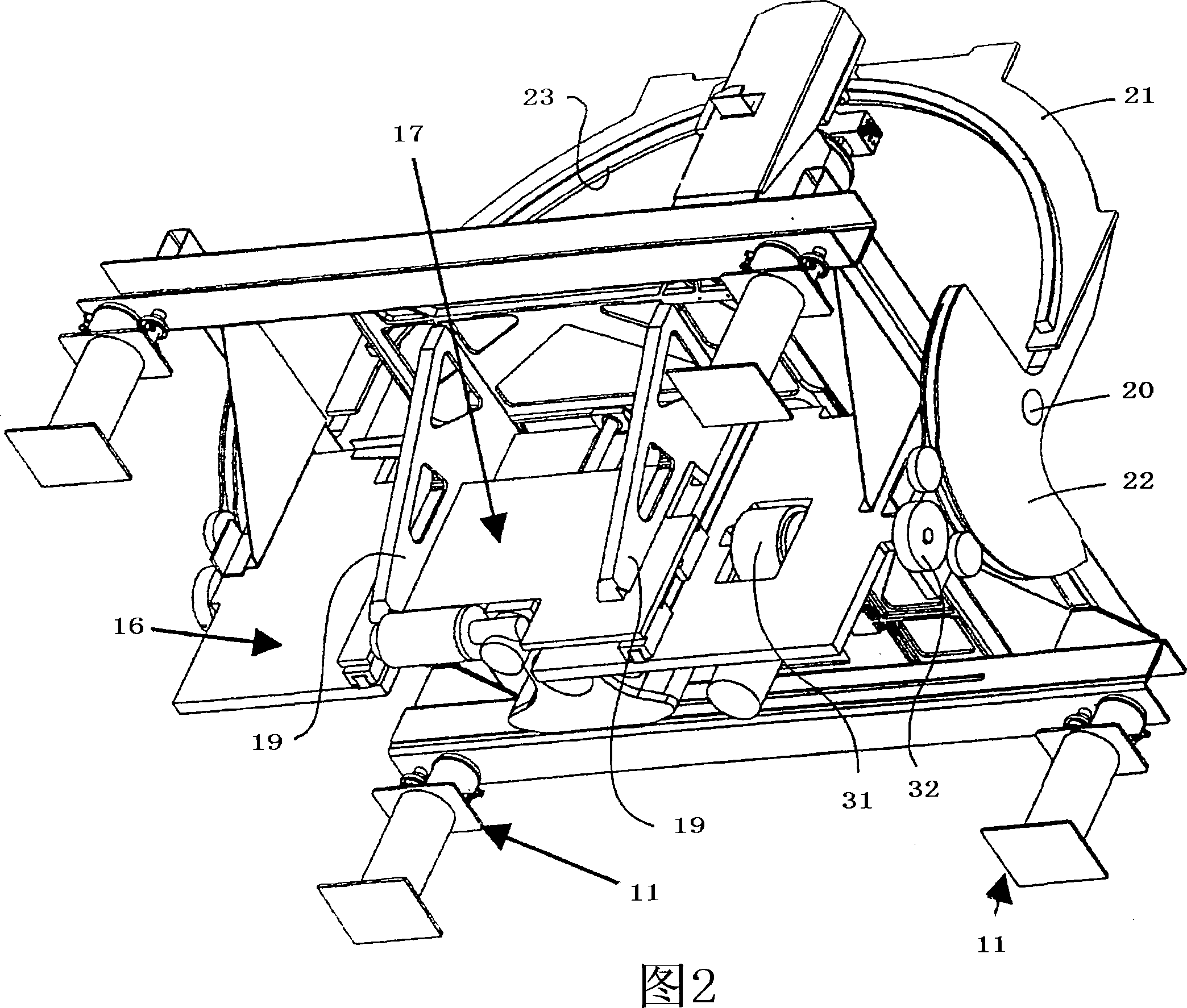

[0025] Referring to the drawings, the frame 10 is supported on feet 11 which are themselves mounted in a cabinet (not shown). The housing is of the usual type and forms a shield to protect the user from the harmful effects of x-rays. An x-ray tube 12 for generating x-rays and an x-ray detector 13 are installed on the frame. Between the tube 12 and the detector 13 there is a movable plate 14 adapted to support the object to be imaged.

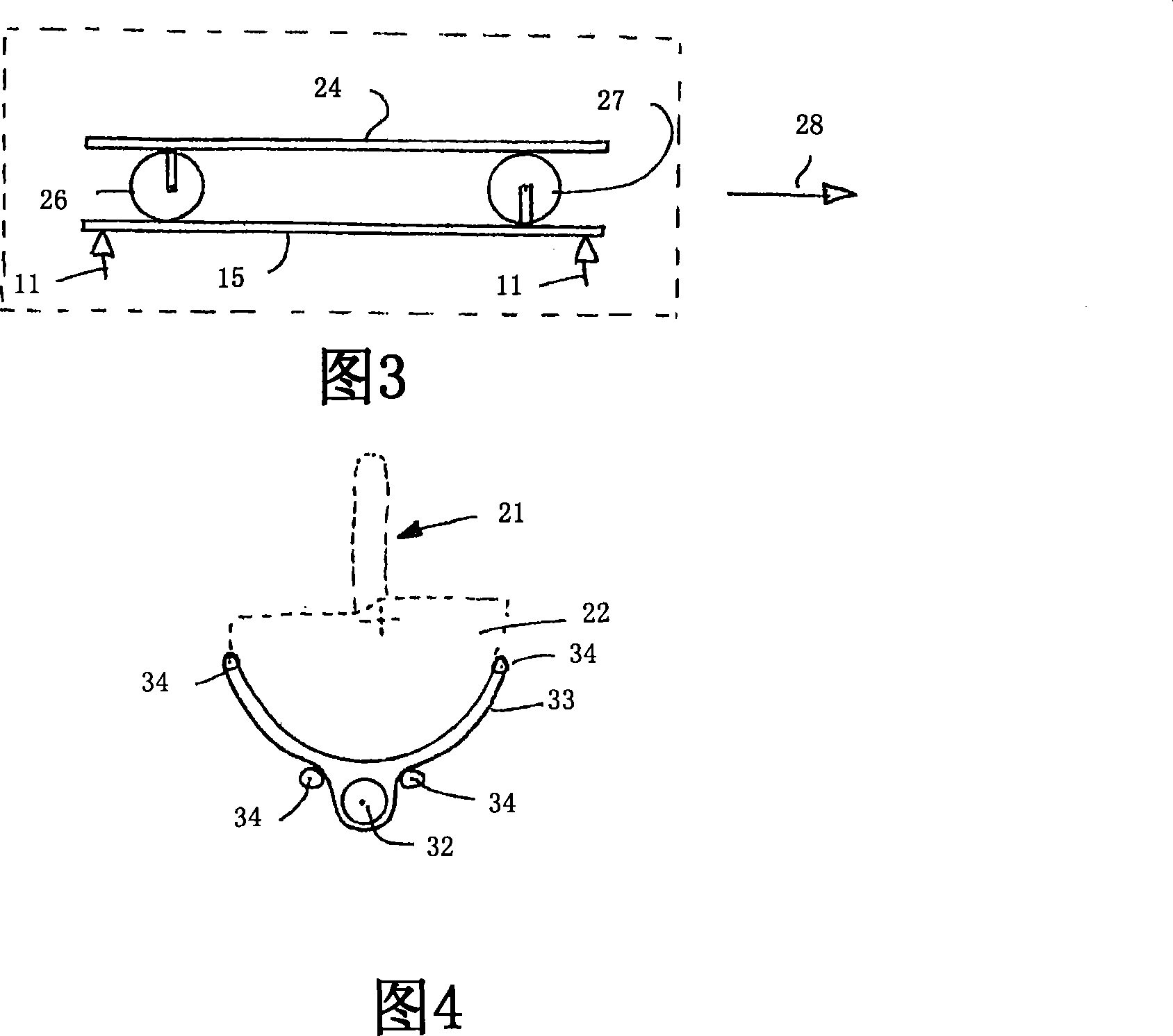

[0026] Each leg 11 includes an anti-vibration mount comprising self-leveling air bearings of known type. Pressurized air is supplied to the bearings and substantially isolates the frame from externally applied vibrations that may be transmitted to the enclosure.

[0027] The air bearings are paired and arranged at the corners of the rectangle. Each pair of bearings 11 supports a corresponding beam 15 on which the frame 10 is mounted.

[0028] The frame 10 comprises a main support plate 16 arranged between beams 15 in a substantially vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com