Continuous production process and apparatus for grinding chip

A production device and production method technology, applied in grinding devices, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of large waste of raw materials, waste of matrix materials, binder materials and abrasive materials, environmental pollution, etc., To achieve the effect of convenient operation, saving raw materials and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

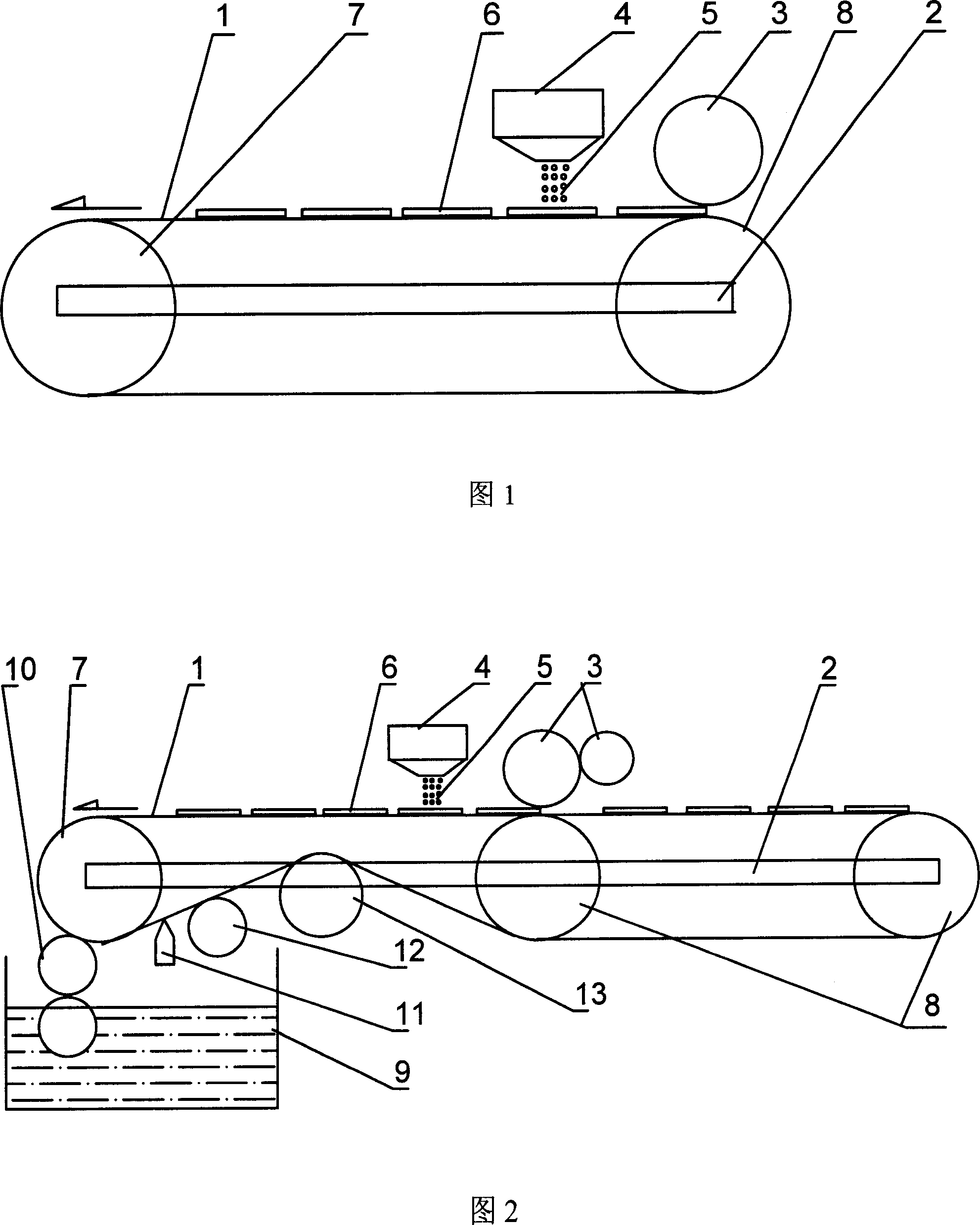

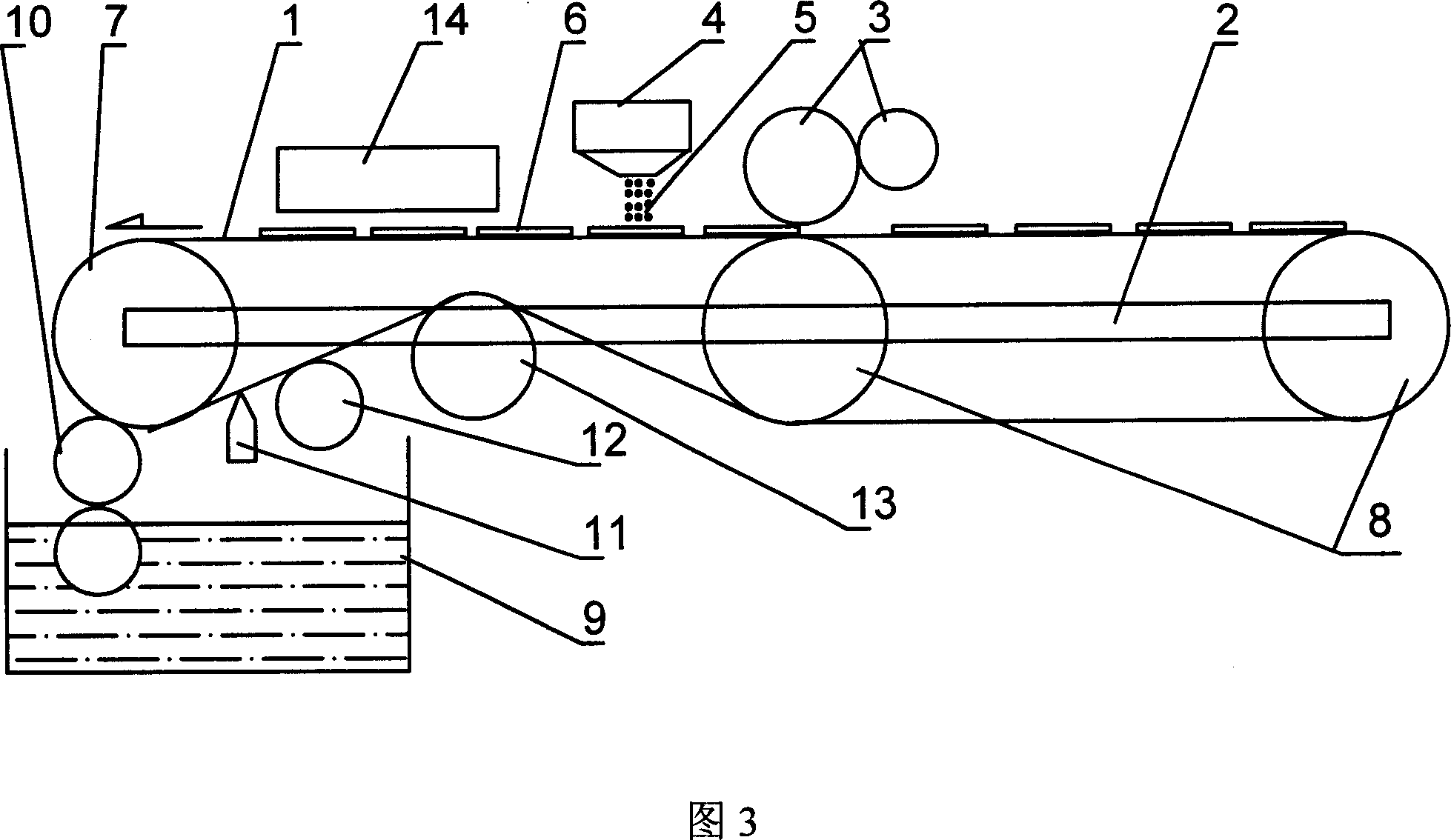

[0020] Embodiments of the present invention: when adopting the continuous production method of the single-chip grinding sheet of the present invention to carry out the production of the grinding sheet, it is preferable to directly make it into the specifications of the required grinding sheet at the stage of making the base material of the grinding sheet A single-piece abrasive sheet substrate with the same size, and then the prepared single-piece abrasive sheet substrate is sequentially passed through an adhesive roller to apply adhesive to its surface, and the surface will be coated with adhesive The abrasive substrates treated with the adhesive are conveyed sequentially through the conveyor belt, and during the conveying process with the conveyor belt, the abrasive substrates treated with the adhesive on the conveyor belt are sequentially passed through a hopper capable of spraying abrasives At the bottom, the abrasive is bonded to the base of the grinding sheet, and then th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com