Burning method and device for energy saving and removing smoke of coal stove

A coal furnace and combustion chamber technology, applied in the field of combustion, can solve the problems of environmental pollution, waste of energy, insufficient combustion of coal, etc., and achieve the effects of protecting the environment, improving combustion efficiency, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

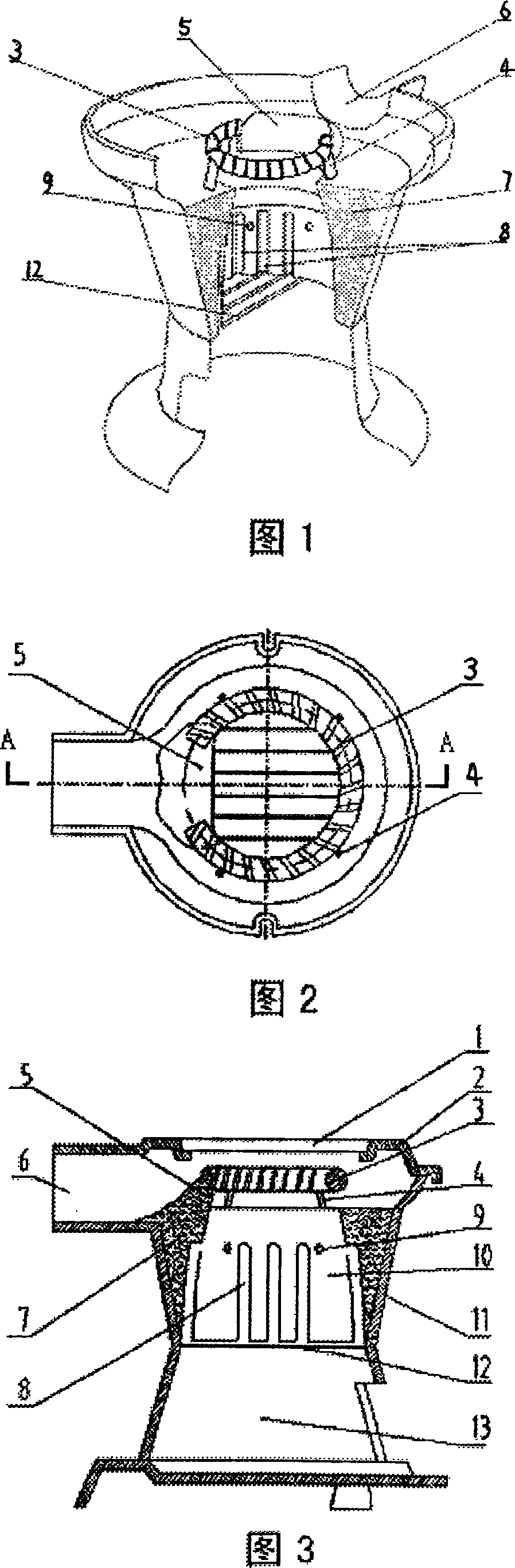

[0013] As shown in Figure 1, the furnace lining 7 is made of pottery clay or inorganic refractory material directly on the inner wall of the furnace body 11 to form a hollow furnace 10 with a bell mouth shape with a large bottom and a small top; the inner wall of the furnace lining 7 has a bottom air inlet 8 from bottom to top. There is a side wall air inlet 9 that penetrates the furnace lining wall on the outer wall of the furnace lining 7; there is a raised part near the smoke outlet 6 on the upper part of the furnace lining 7 as a fire wall 5; The unclosed combustion circle 3, the unclosed part of the combustion circle 3 sandwiches the raised fire-retaining wall 5, the distance between the upper edge of the combustion circle 3 and the burner basin 2 is 15mm; four steel bars with a height of 19mm are welded under the combustion circle 3 Support 4, steel bar support 4 is placed on furnace lining 7.

[0014] After many tests, we have adjusted the thickness of the threaded stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com