Back light module and liquid crystal display device

A technology of backlight module and light source, applied in optics, nonlinear optics, static indicator, etc., can solve the problem of inconvenient assembly of backlight module, and achieve the effect of simplifying assembly steps, convenient assembly, and simple assembly action.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

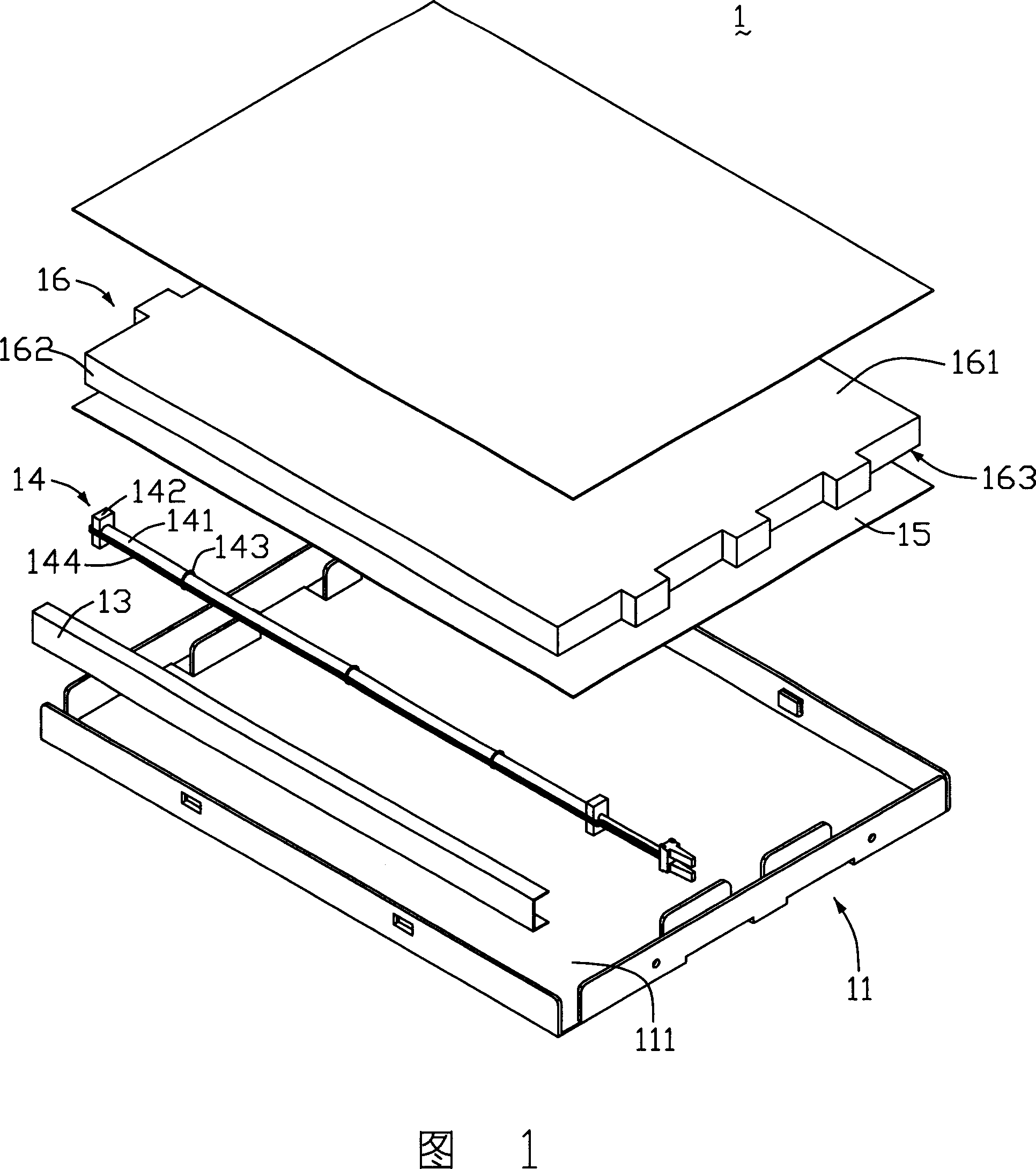

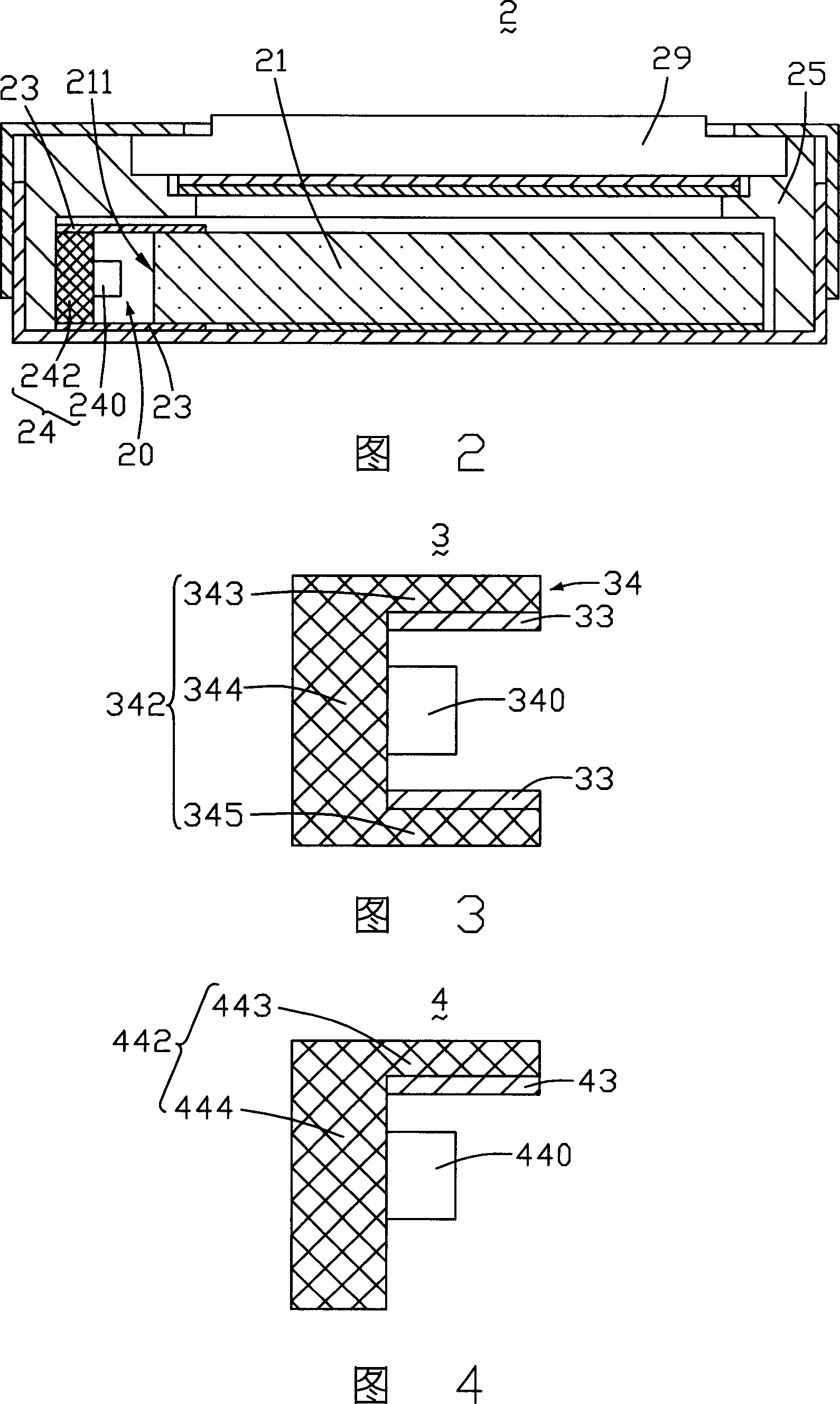

[0018] Please refer to FIG. 2 , which is a cross-sectional view of the first embodiment of the liquid crystal display device of the present invention. The liquid crystal display device 2 includes a backlight module 20 and a liquid crystal panel 29 arranged opposite to the backlight module 20. The backlight module 20 includes a The light guide plate 21 on the light incident surface 211 , a light source 24 disposed adjacent to the light incident surface 211 , and a frame 25 accommodating the light guide plate 21 and the light source 24 .

[0019] The light source 24 includes a strip support 242 , a plurality of LEDs 240 disposed on the strip support 242 , and two reflective elements 23 adjacent to the LEDs 240 . The plurality of LEDs 240 are arranged in a row. The strip-shaped support 242 is a cylinder on which a circuit is arranged, and the external power supply lights up the light-emitting diode 240 through wires (not shown) and the circuit on the strip-shaped support 242 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com