Refrigeration machine and method for operating refrigeration machine

一种制冷机、制冷剂的技术,应用在热力泵,操作该制冷机领域,能够解决压缩机机械性磨损、破坏、削弱热力泵经济性等问题,达到降低冻结的危险、改善经济性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

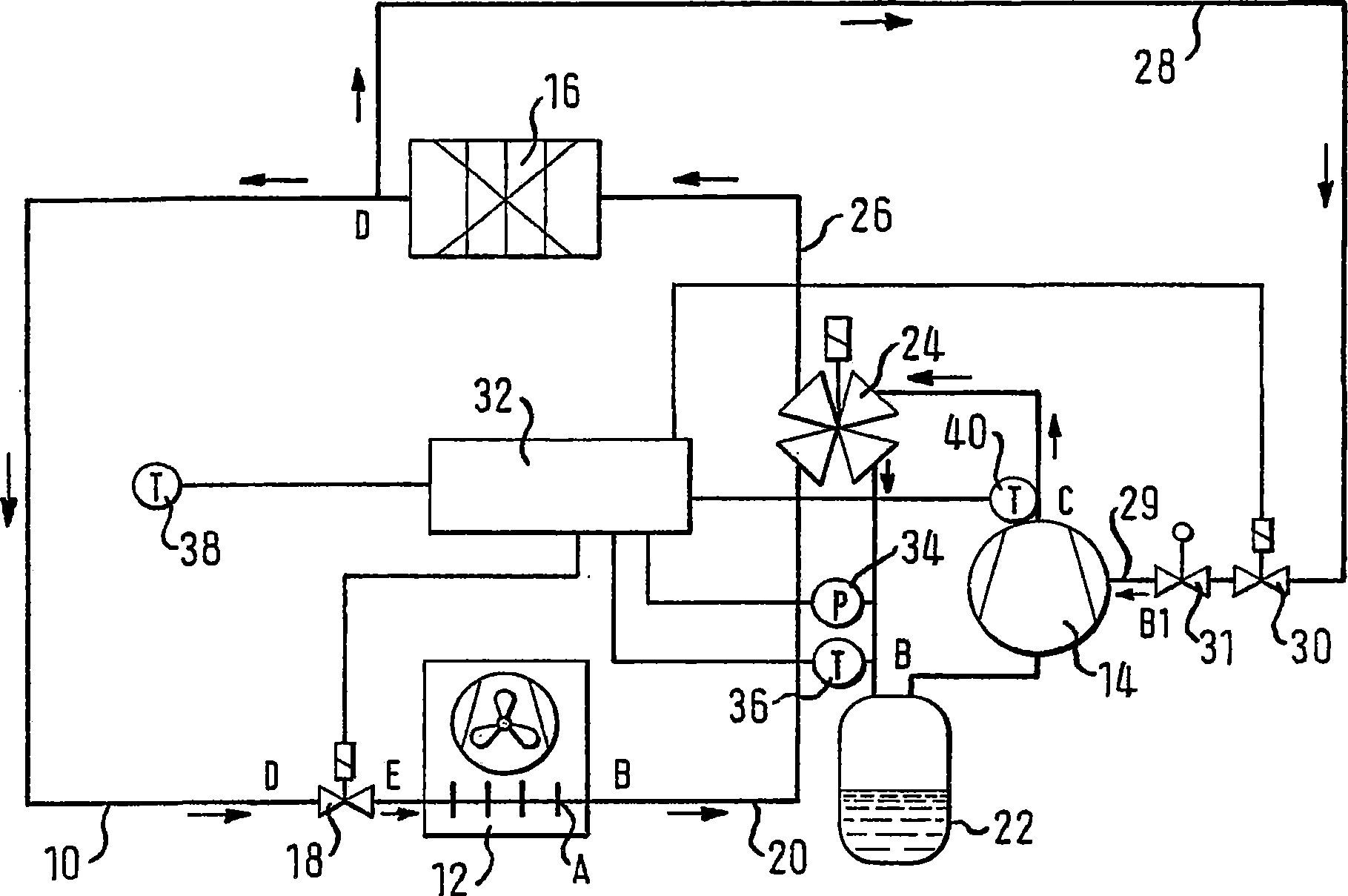

[0036] figure 1 The refrigerator according to the present invention shown in and described here as a function of a heat pump includes a closed loop 10 with a refrigerant. In the refrigerant circuit 10, an evaporator 12, a compressor 14, a condenser 16, and an electrically driven expansion valve 18 are sequentially provided.

[0037] The evaporator 12 and the compressor 14 are connected to each other through an air extraction pipe 20. Because the compressor 14 is designed to compress only evaporated refrigerant and may be damaged by inadvertent leakage of liquid refrigerant, the liquid separator 22 in the suction line 20 is arranged upstream of the compressor 14. The liquid separator separates and collects the liquid refrigerant that has not been completely evaporated in the evaporator 12 and / or has liquefied in the suction line 20 from the refrigerant flow.

[0038] The four-way switching valve 24 in the suction line 20 is provided upstream of the liquid separator 22, and the four...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com