Transformer for inverter

A technology of transformers and inverters, applied in the direction of transformer/inductor core, transformer/inductor components, transformer/inductor coil/winding/connection, etc., can solve the transformer size limitation and circuit matching cannot be maximized , changes in other characteristics, etc., to achieve the effect of minimizing copper loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

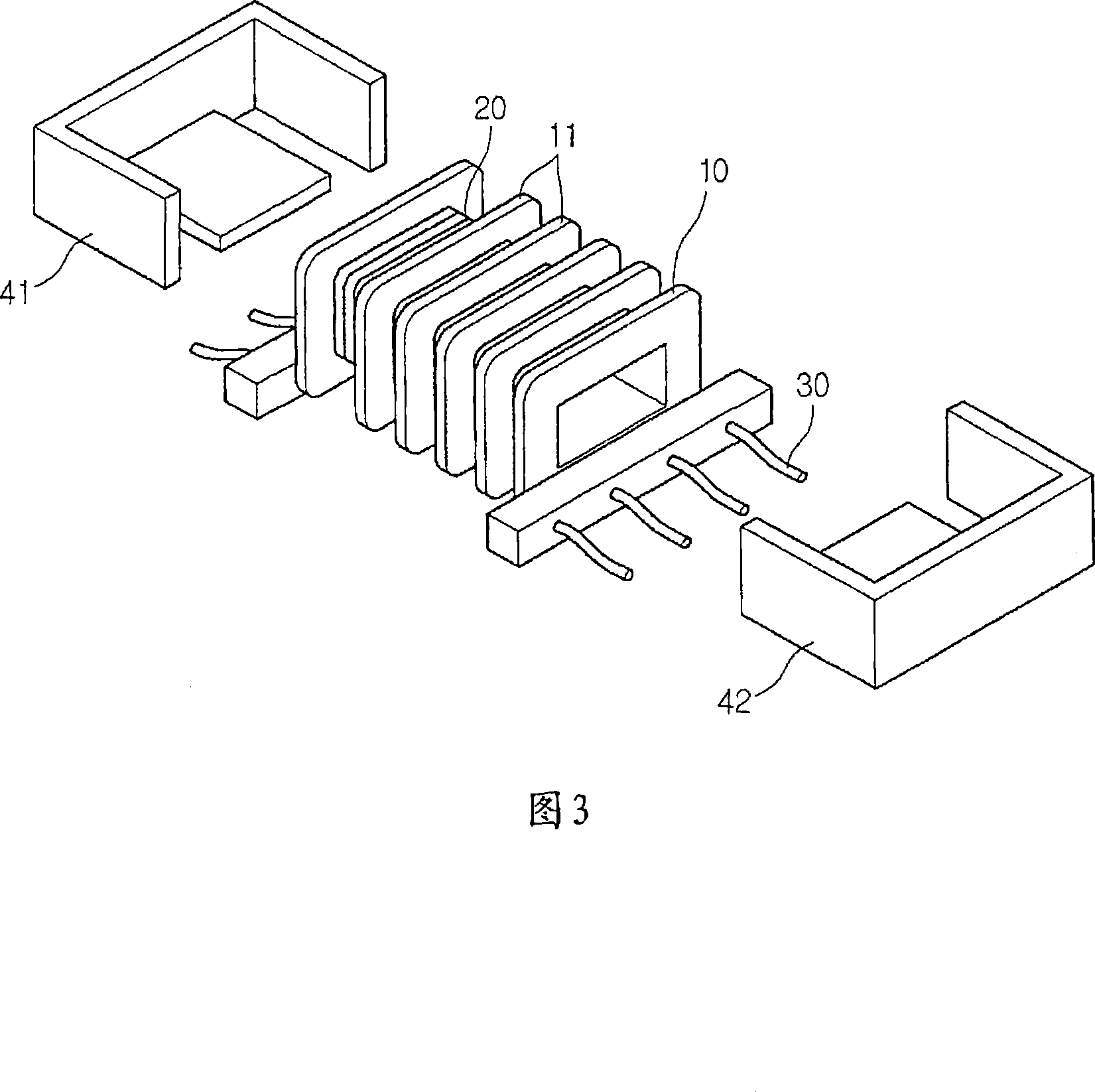

[0036] 3 is an exploded perspective view of a transformer of a lamp driving circuit according to one embodiment of the present invention, and FIG. 4 is a cross-sectional view illustrating a winding method of the transformer of the lamp driving circuit according to one embodiment of the present invention.

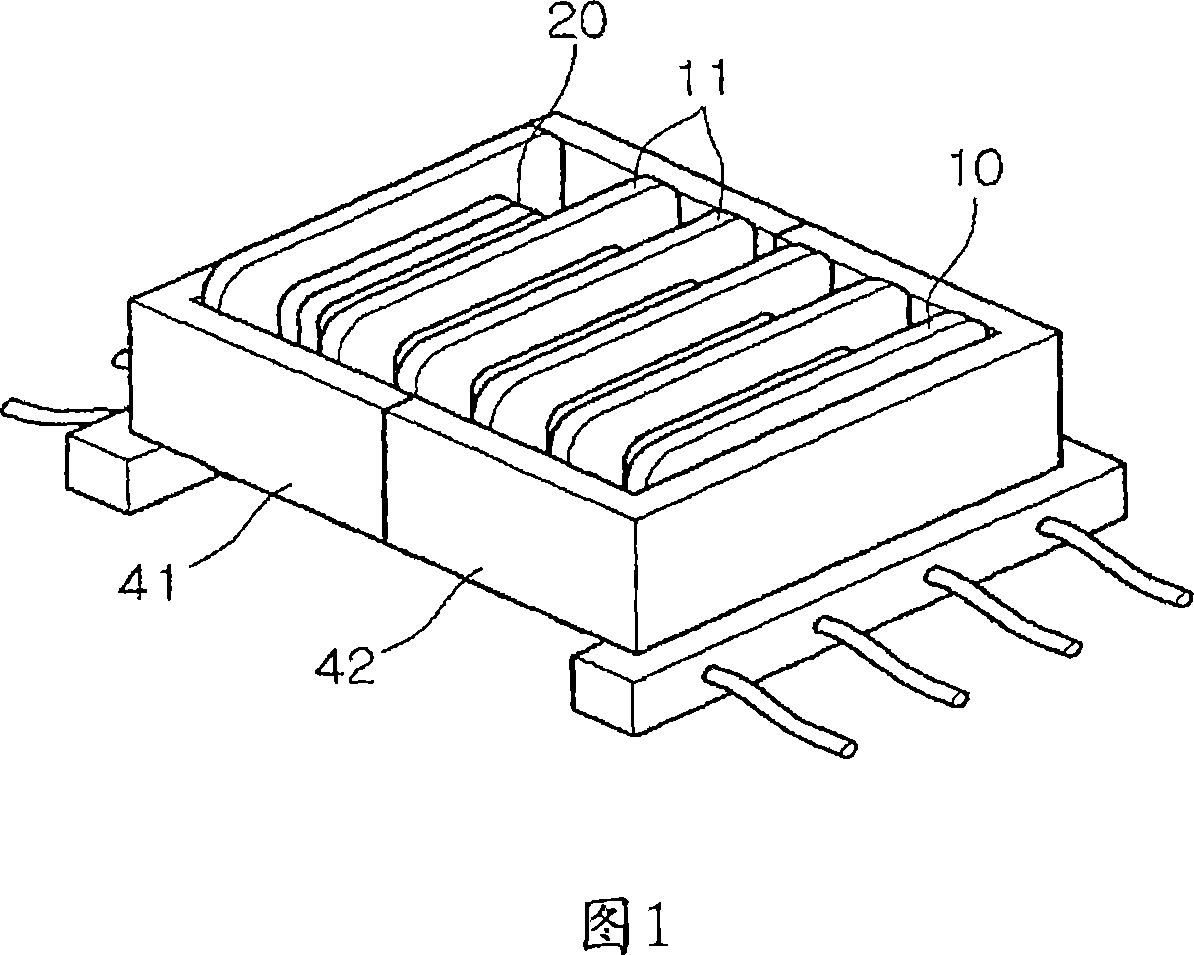

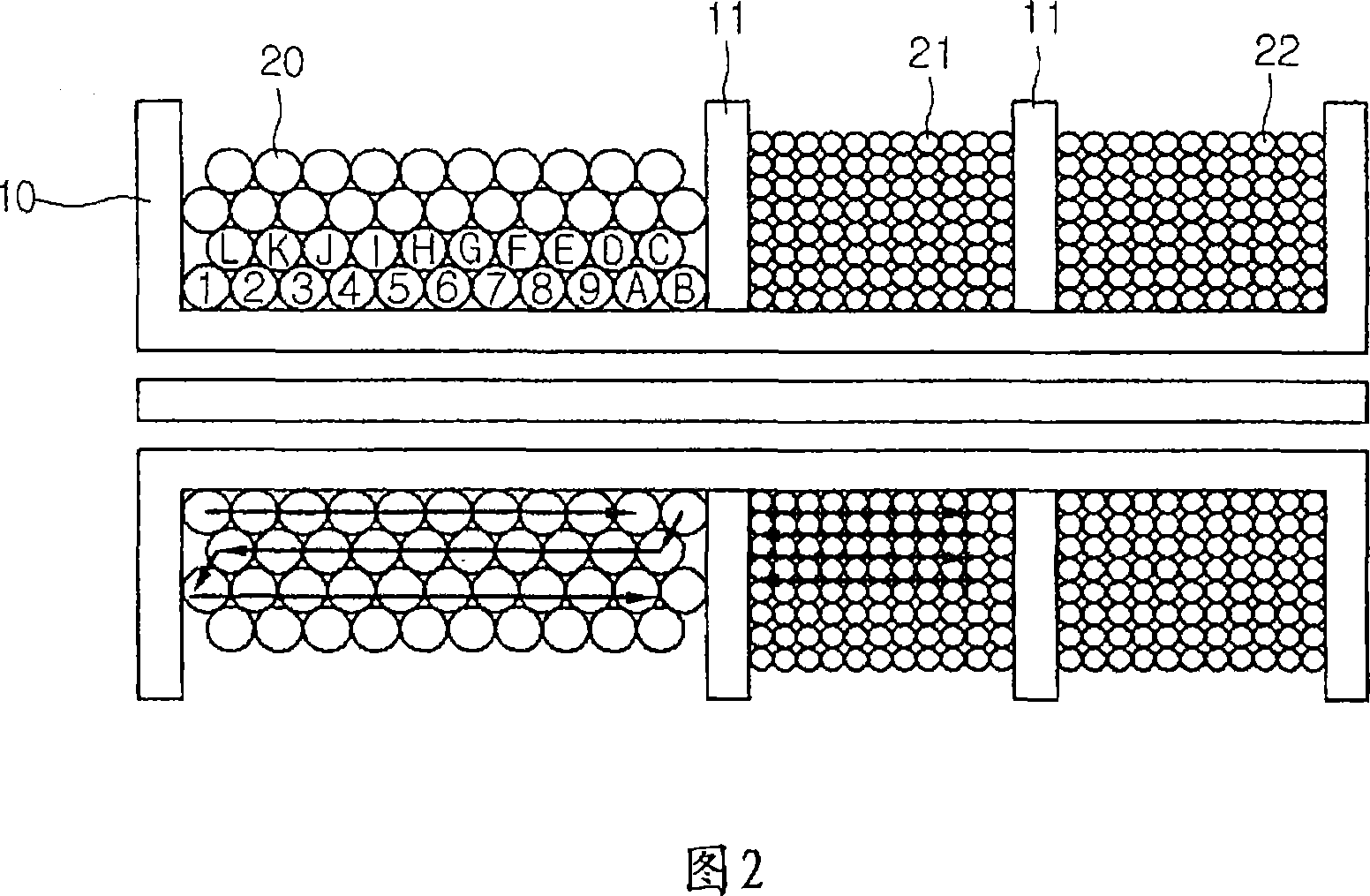

[0037] Referring to FIGS. 3 and 4 , a transformer for an inverter includes a bobbin 10 and ferrite cores 41 and 42 . The coil 20 is wound around the bobbin 10 and the barriers 11 are regularly formed in the bobbin 10 to be spaced apart from each other. Ferrite cores 41 and 42 are inserted into the central portion of the bobbin 10 .

[0038] The bobbin 10 having the barrier rib 11 is an injection-molded product of LCP or phenolic material, and the ferrite cores 41 and 42 are formed of fine oxides of nickel, zinc, or manganese and guide magnetic flux.

[0039] The ferrite cores 41 and 42 are formed in an E-shape, and their central portions pass through the bobbin 10 . The si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com