Washing machine with high-position lifting directed spraying system

A technology of directional spraying and high-level lifting, applied in the field of washing machines, can solve problems such as low efficiency, no specific structure of atomization device is proposed, and achieve the effect of avoiding uneven distribution of droplets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

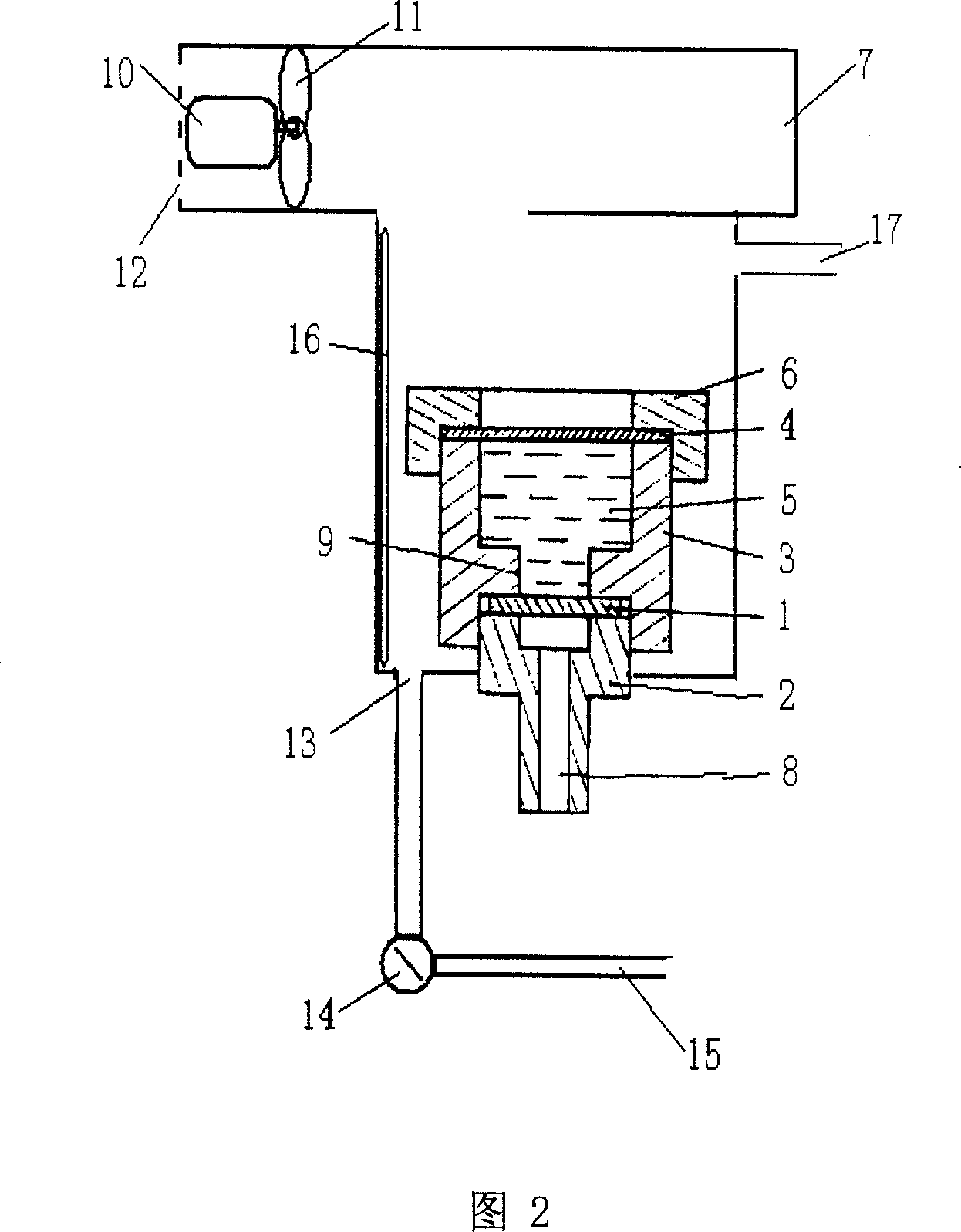

[0013] The specific embodiments of the present invention will be described below with reference to the accompanying drawings. It should be noted that the following embodiments do not limit the technical scope of the present invention.

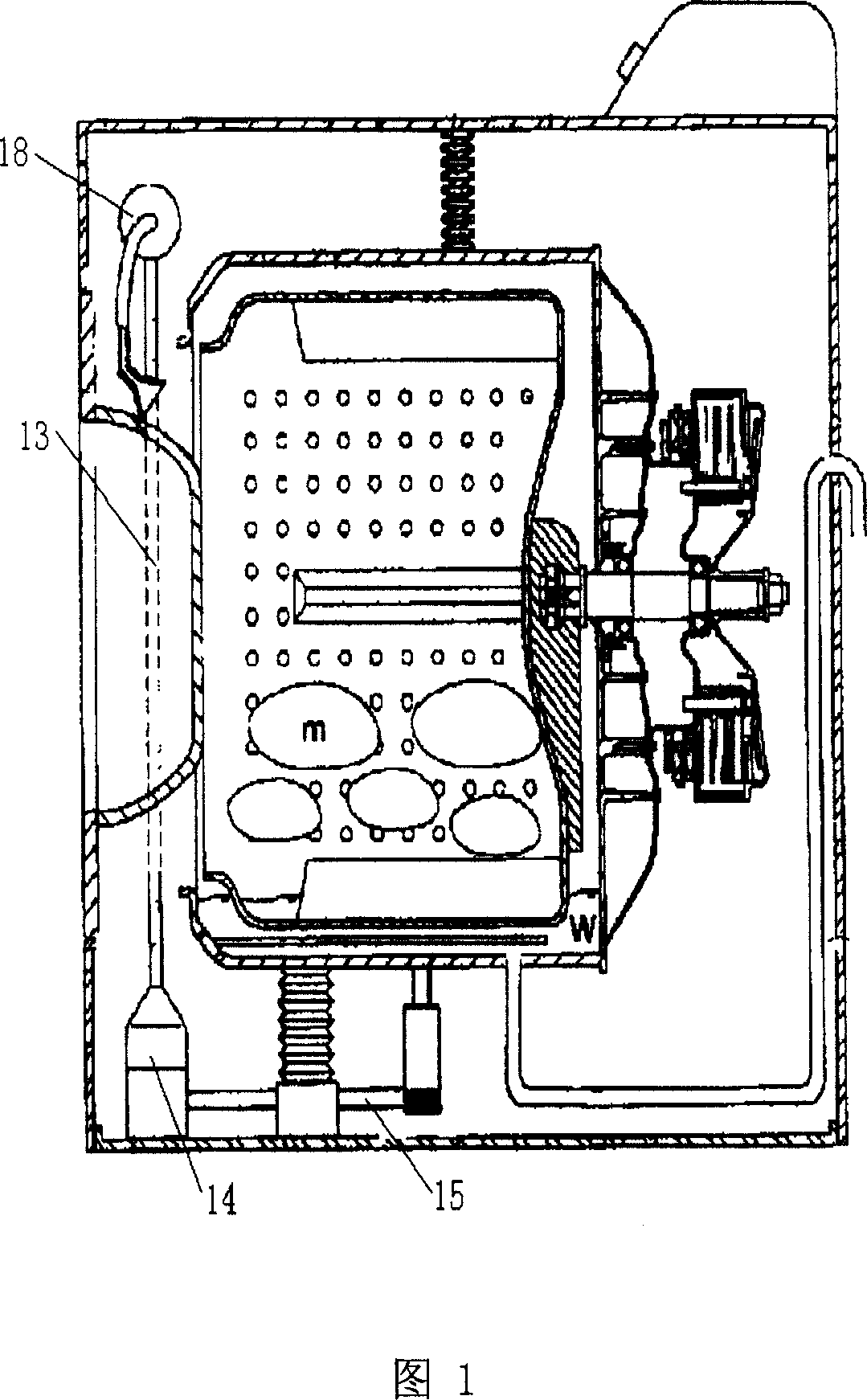

[0014] The washing machine of the high-level lifting directional spraying system according to the present invention mainly consists of the washing machine and the high-level lifting directional spraying system.

[0015] Said washing machine is any type of washing machine in the prior art, as long as such a system is needed, the device of the present invention can be used.

[0016] The high-level lifting directional spraying system of the present invention is mainly composed of three parts, namely high-level lifting, directional spraying and atomization device.

[0017] The high-level lifting described in the present invention adopts the lifting pump 14, and the liquid to be atomized is lifted into the directional spraying system 18 by connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com