X-CT scanning system

一种扫描系统、X-CT的技术,应用在X-CT扫描系统领域,能够解决增加系统硬件复杂性和开销、增加计算量、降低重建速度等问题,达到节省探测器尺寸、减少投影数据量、降低硬件成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

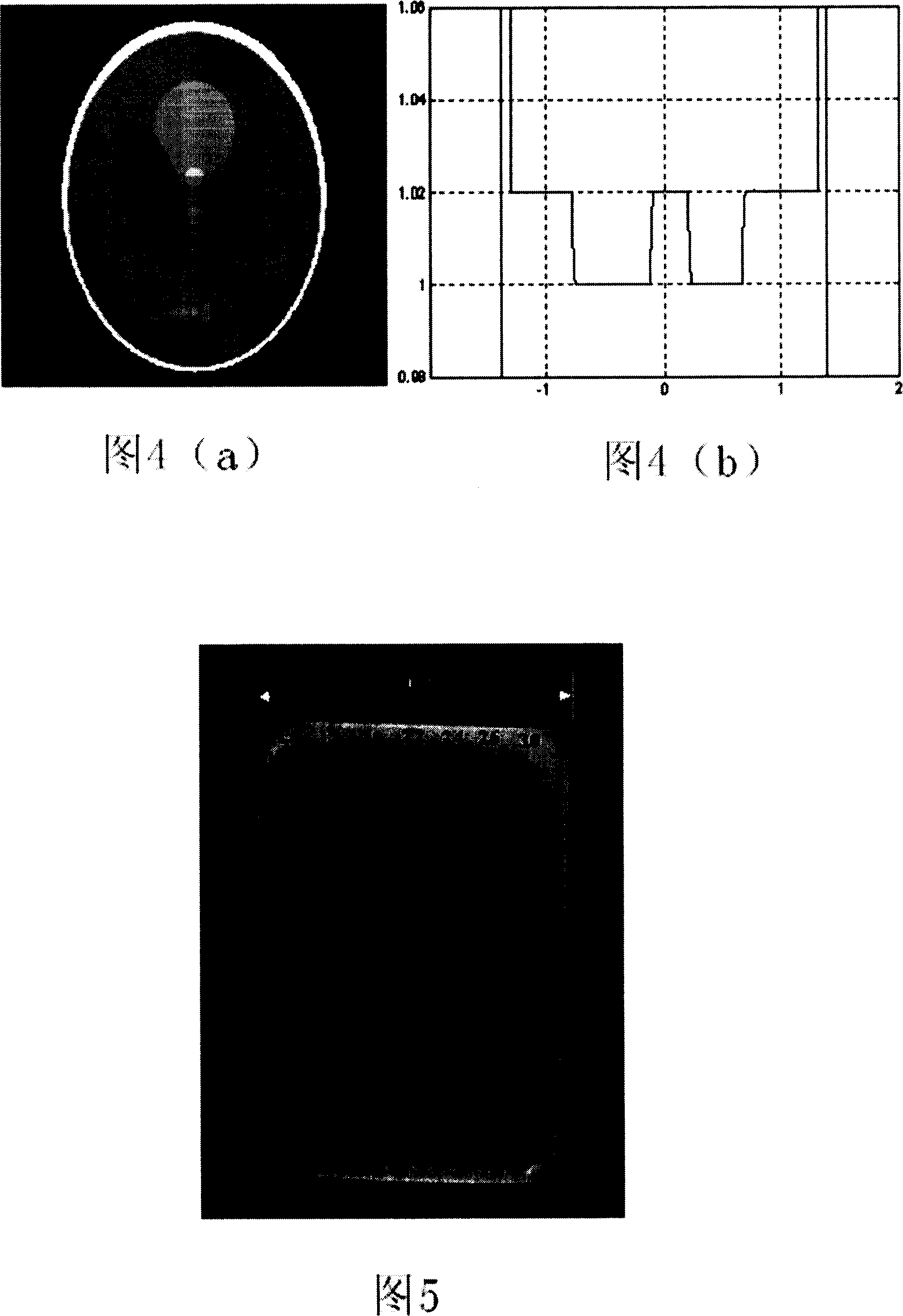

[0023] The following examples are used to illustrate the present invention, but are not intended to limit the protection scope of the present invention.

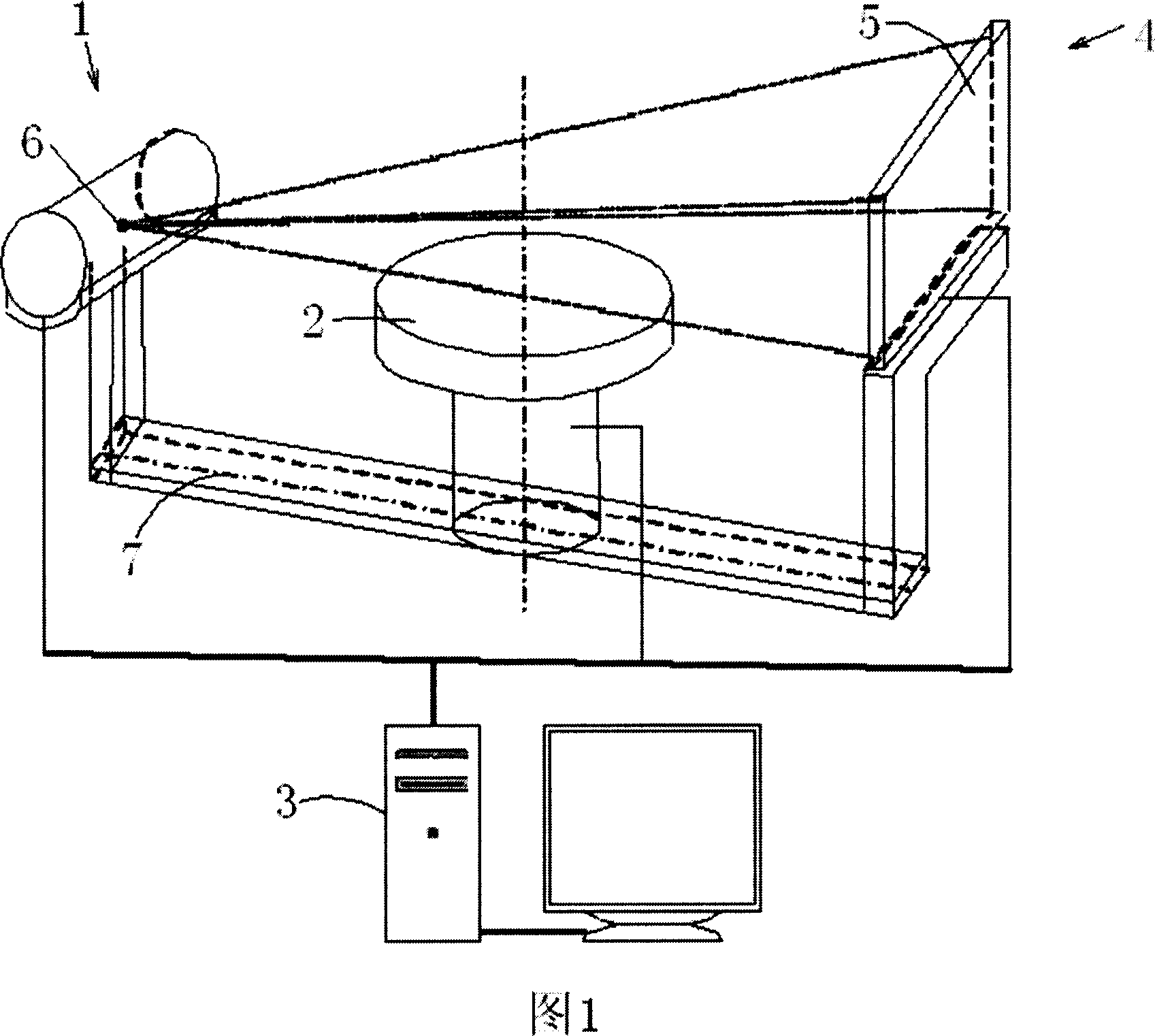

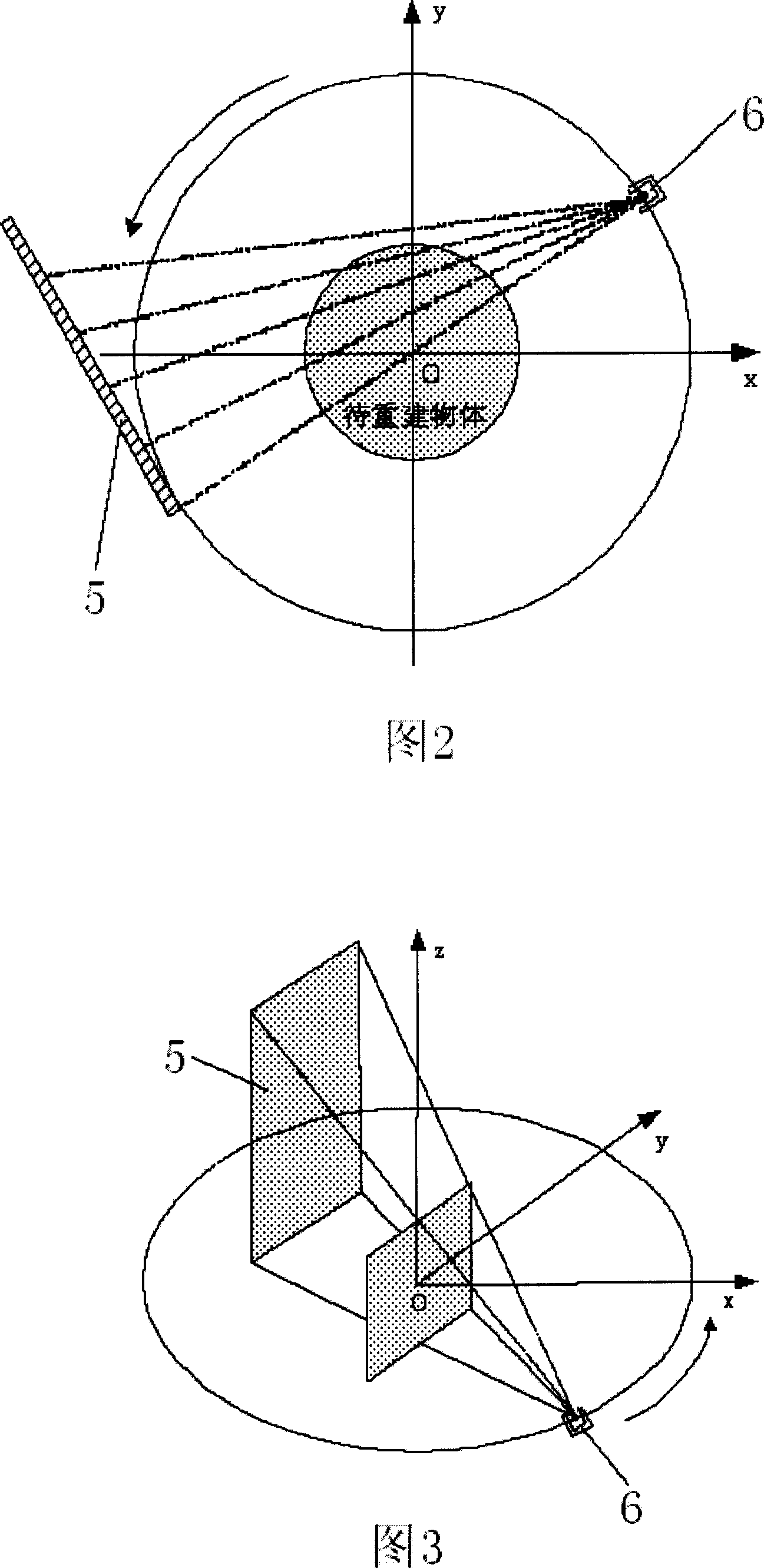

[0024] See Figures 1 and 2. The fan beam X-rays in Figure 2 cover only half of the object to be inspected. The X-CT scanning system of the present invention includes a main control and data processing computer 3, a base 7, an object turntable located in the middle of the base 7 for placing workpieces to be inspected and its mechanical control device 2, and X-ray generators located on both sides of the base 7. Device 1 and data acquisition system. Wherein, the data acquisition system includes a linear array detector, a readout circuit and a logic control unit for detecting X-ray projection data and projection data on the detector, and the main control and data processing computer 3 is used to be responsible for the operation of the X-CT system The main control of the process, and process the projection data obtained by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com