Method for operating an internal combustion engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

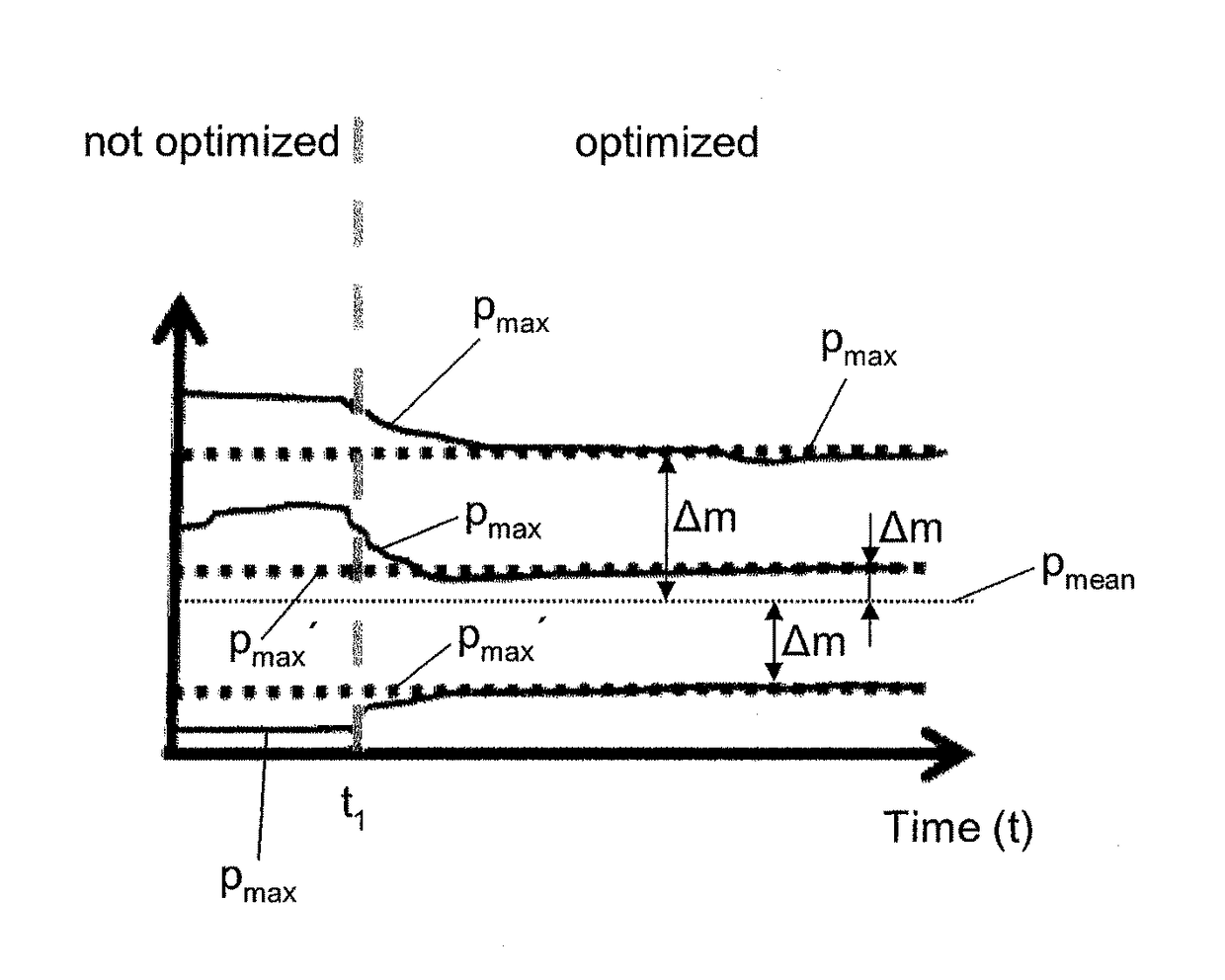

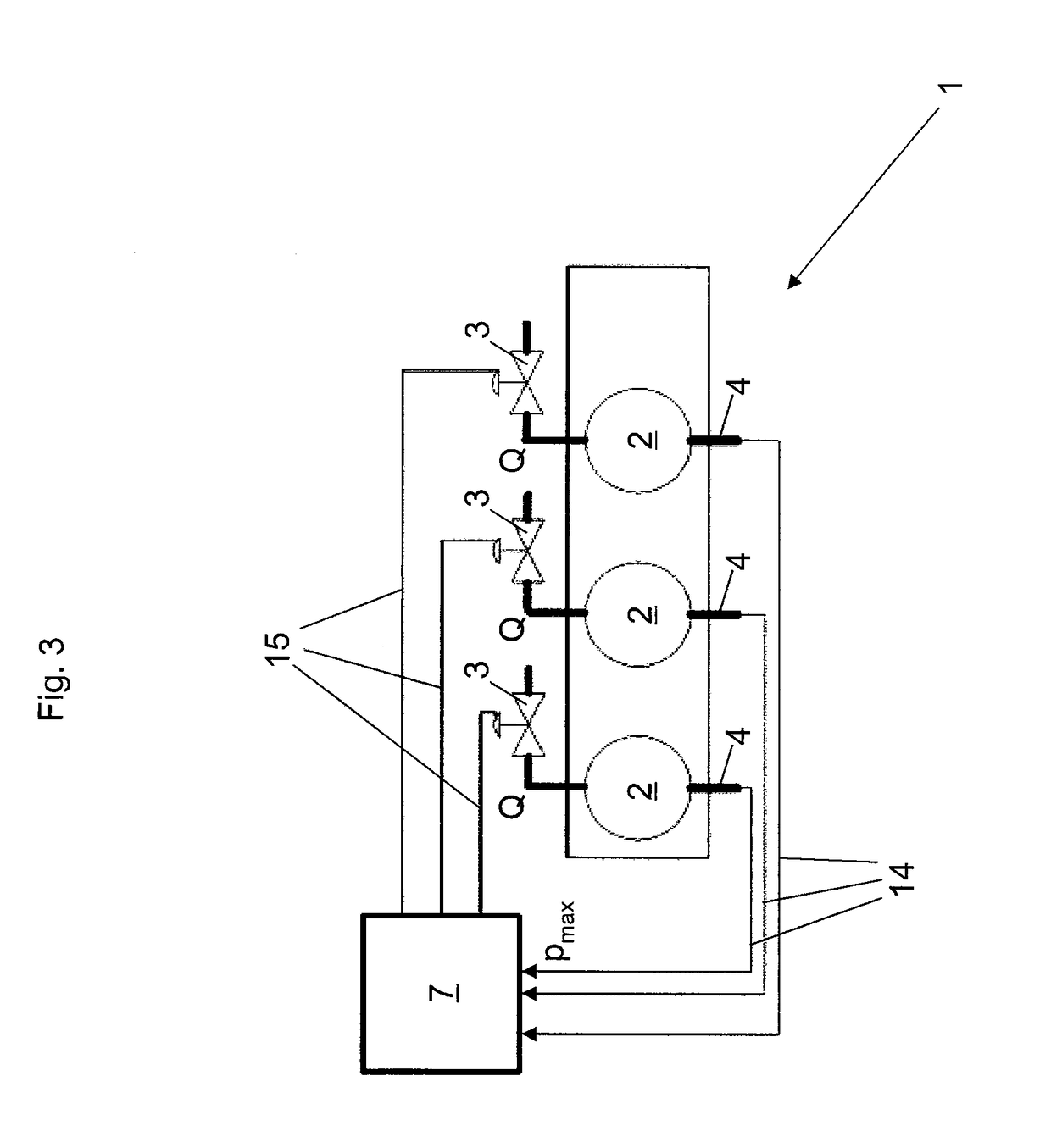

[0061]FIG. 1 shows, by way of example, the cylinder efficiencies ηcyl of two cylinders 2 of an internal combustion engine 1 (see FIG. 3) as a function of their respective NOx emissions Ecyl as well as desired target values to be obtained with the proposed method for the NOx emissions Ecyl′ and for the cylinder efficiencies ηcyl′ of all cylinders 2.

[0062]The profile of a cylinder efficiency ηcyl to be obtained exhibits therein a non-linear dependency on the respective NOx emission Ecyl of the corresponding cylinder 2. The different NOx emissions Ecyl shown and the associated respectively different cylinder efficiencies ηcyl of the cylinders can in particular be caused by cylinder-specific differences in cylinder parameters—such as different air charges, deposits and wear, centers of combustion, or mechanical tolerances of the cylinders 2.

[0063]By means of the proposed method, these different cylinder-specific cylinder parameters can be taken into account, since for each cylinder 2, a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap