Front-loader dishwashing machine with heat recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

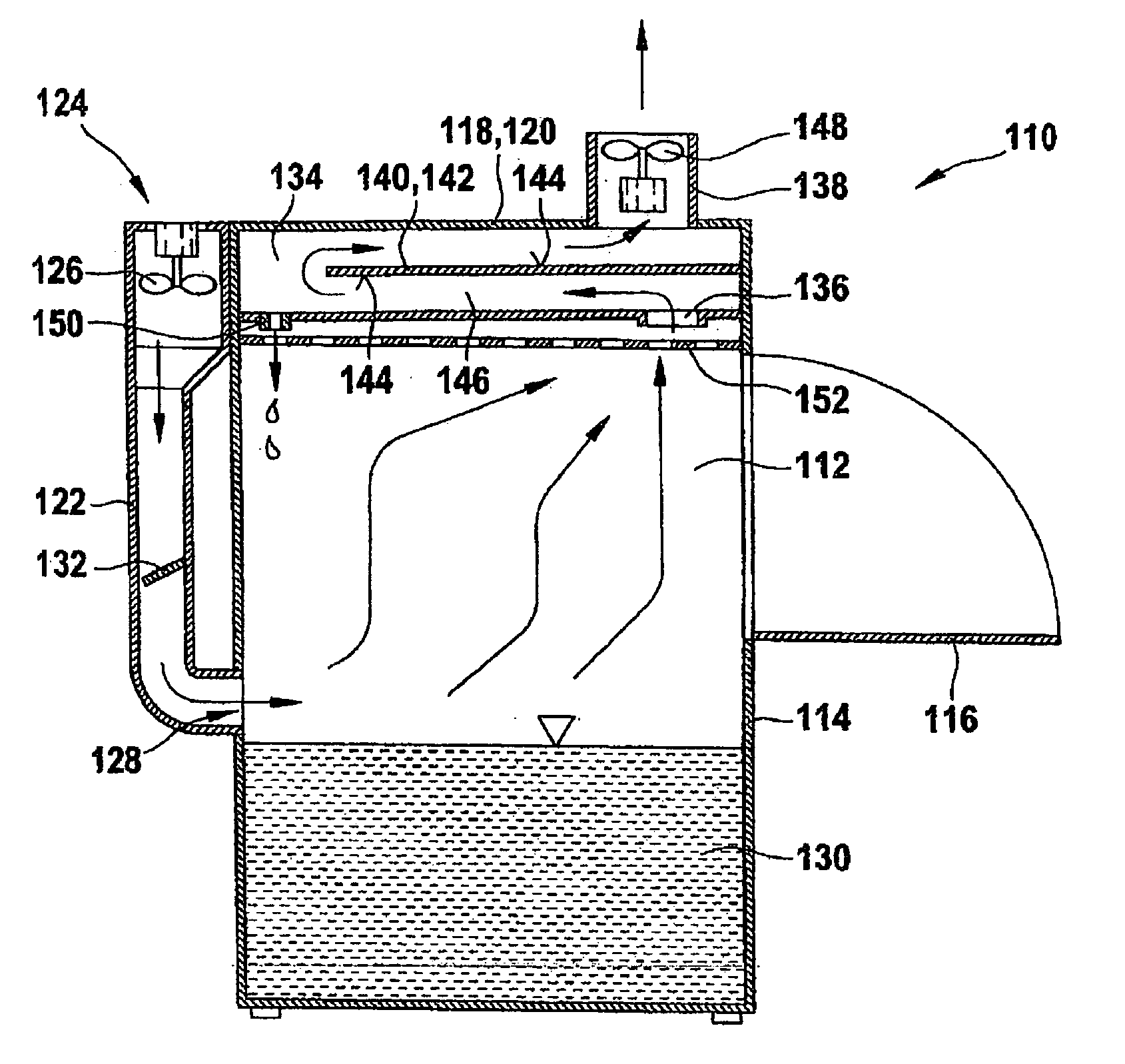

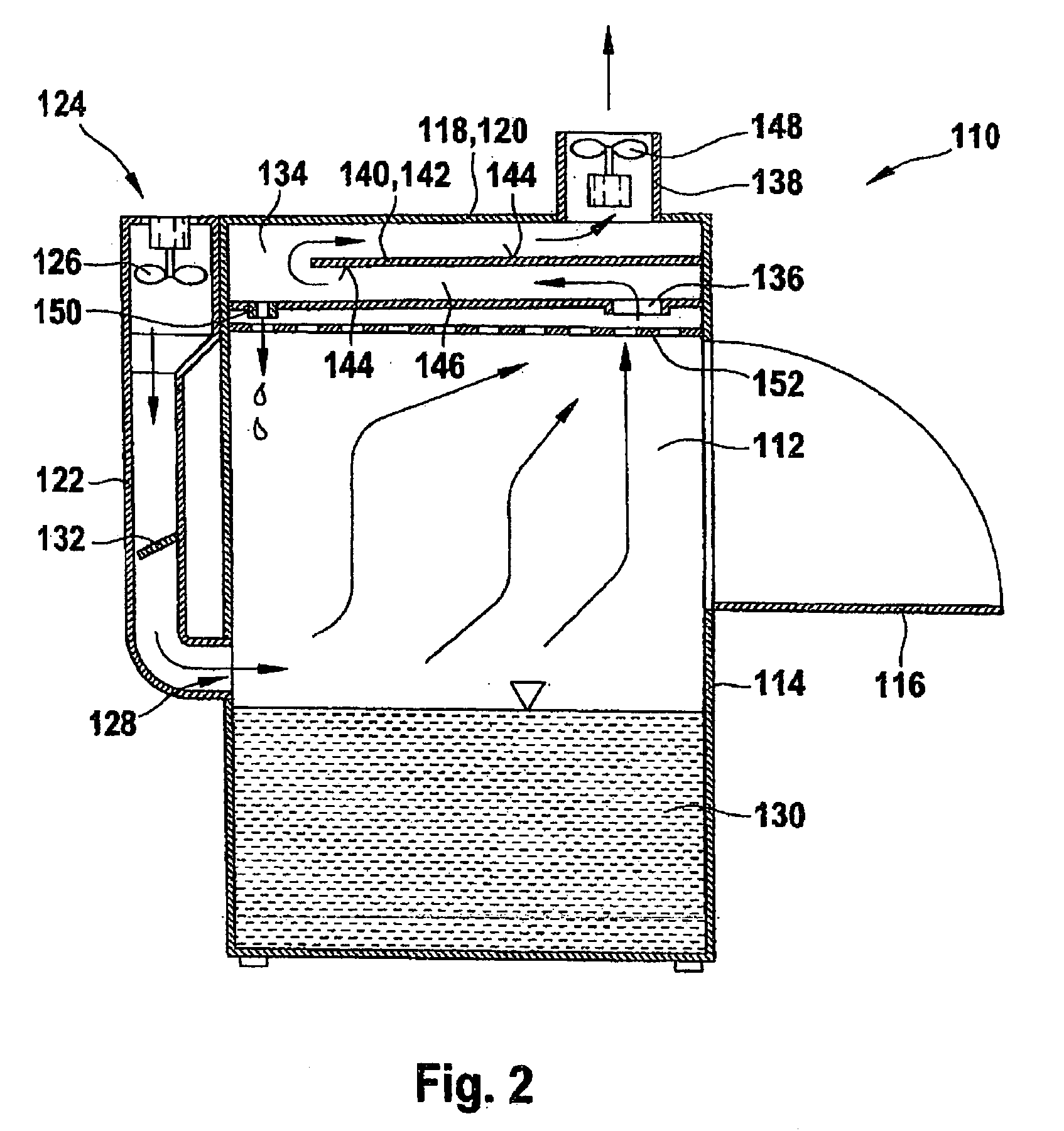

[0040]FIGS. 1 and 2 show an embodiment of a dishwashing machine 110 according to the invention, illustrated schematically. The dishwashing machine 110 is in the form of a front-loader and has a dishwashing chamber 112 with a housing 114. On its front, the housing 114 has a front door 116, which can be folded downward in this embodiment, in order to allow items to be cleaned to be loaded in the dishwashing chamber 112. This loading process can be carried out either directly, by placing items to be cleaned in appropriate holders within the dishwashing chamber 112, or this can be done by the use of baskets for the items to be cleaned. Items to be cleaned and the corresponding devices are not illustrated in FIGS. 1 and 2.

[0041]As can be seen in particular from the section illustration in the form of a side view shown in FIG. 2, the dishwashing machine 110 has a cover part 118 which is in the form of a condensation precipitation device 120. Furthermore, this exemplary embodiment of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com