Compressor device and a cooler thereby used

a compressor device and cooler technology, applied in the direction of machines/engines, liquid fuel engines, light and heating apparatus, etc., can solve the problems of affecting the cooling effect of the compressor device, the temperature of the coolant when leaving the compressor device is relatively low, and the parallel supply is not optimal, etc., to achieve the effect of low compression efficiency, good heat recovery possibility, and less emphasis on compression efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

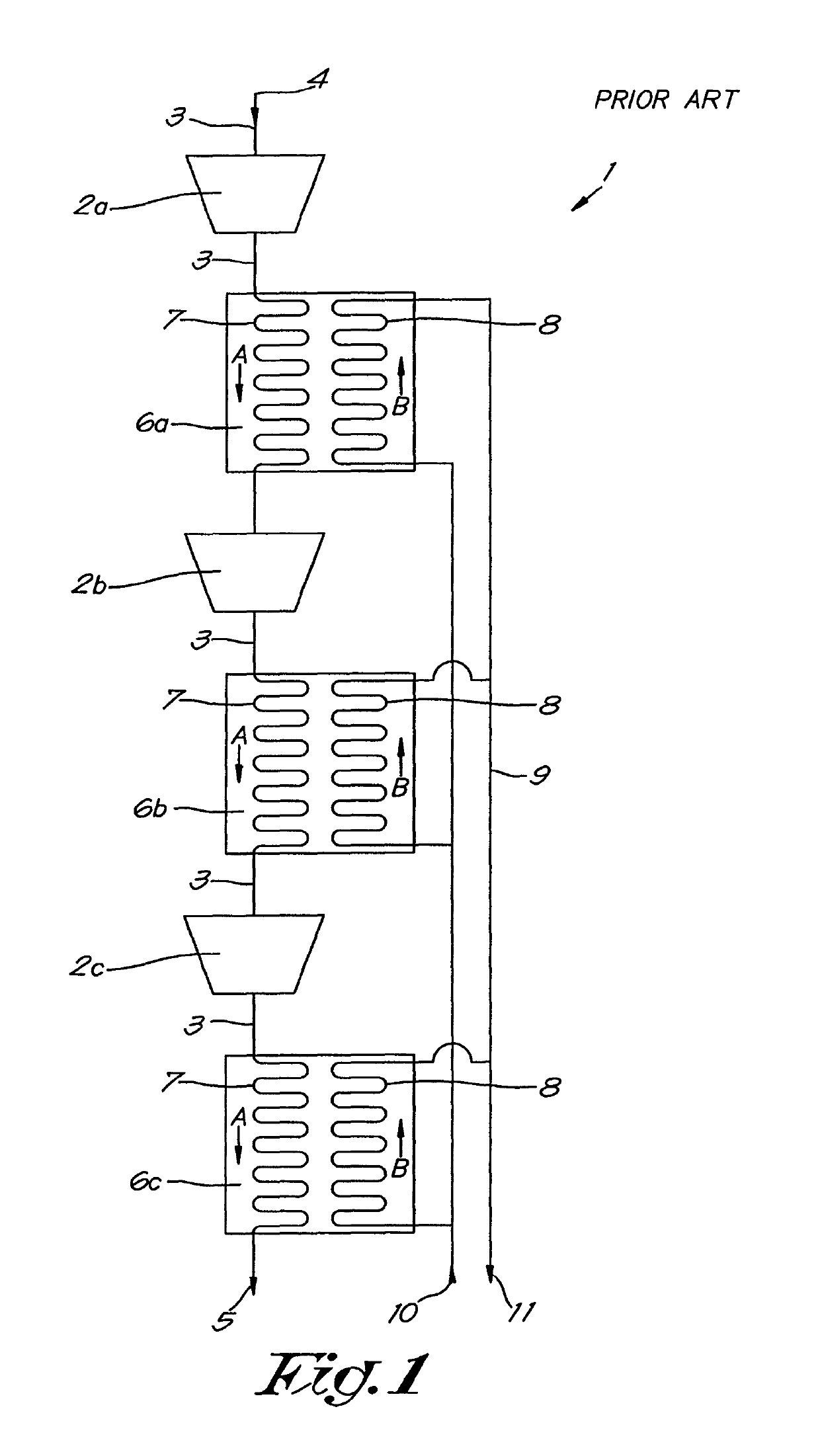

[0043]FIG. 1 shows a conventional compressor device 1 according to the state of the art with three compressor elements 2, respectively 2a, 2b and 2c, which are connected together in series between an inlet 4 and an outlet 5 by means of pipes 3.

[0044]Downstream from each compressor element 2 there is a cooler for cooling the compressed gas, respectively an ‘intercooler’6a between the compressor elements 2a and 2b, an intercooler 6b between the compressor elements 2b and 2c, and an ‘aftercooler’6c after the last compressor element 2c.

[0045]The intercoolers 6a and 6b are thereby intended to cool to a maximum the temperature of the compressed gas from a previous compressor element 2 before being drawn in by a subsequent compressor element 2, and this is to ensure that the efficiency of the compression in the compressor is optimum.

[0046]The aftercooler 6c ensures cooling of the compressed gas before it leaves the compressor device 1 according to the invention via the outlet 5, and this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com